Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318306805 bracket XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Support (Part No. 318306805): Robust Support for Stable Component Operation

In the overall structure of the XCMG XE2000 excavator, the support is a crucial load-bearing component that supports core components and maintains the structural stability of the equipment. The support, part number 318306805, is specifically designed for securing important components of the XE2000 excavator. With its superior structural strength and load-bearing capacity, it provides a robust guarantee for the safe operation of the equipment’s components during high-intensity operations.

This support is integrally welded from high-strength low-alloy structural steel. Key stress-bearing parts have undergone forging reinforcement treatment, achieving high industry standards for yield strength and tensile strength. Facing the gravity, vibration, impact, and workload transmitted by various components during XE2000 excavator operation, the 318306805 bracket evenly distributes the force to the machine body, effectively resisting the risk of deformation and breakage. This ensures the supported components remain in a stable installation position, reducing component displacement and damage caused by bracket failure at its source, and guaranteeing continuous operation of the equipment.

From a structural design perspective, the 318306805 bracket’s load-bearing structure has been optimized through finite element analysis, employing a box-type or I-beam cross-section design. This significantly improves overall rigidity and torsional resistance while reducing its own weight. The bracket’s mounting holes and connection interfaces are precision-machined to perfectly match the connection dimensions of the supported components and the machine body, ensuring no stress concentration after assembly and extending the service life of both components and the bracket. The bracket’s reinforcing ribs are rationally arranged to address the stress characteristics of different operating scenarios, with a focus on strengthening weaker areas to further enhance structural stability.

In terms of load-bearing performance, this bracket has undergone rigorous load testing and can stably withstand the weight of the corresponding components and the additional forces generated during operation. Whether supporting large components like hydraulic tanks and radiators, or fixing precision devices like valve assemblies and motors, this bracket maintains a stable support, preventing components from swaying or shifting during vibration and bumps. This ensures the components maintain their normal operating posture and reduces the risk of performance loss or malfunction due to unstable installation.

Regarding compatibility, the bracket (part number 318306805) is an original accessory for the XCMG XE2000 excavator, precisely matching the installation requirements of the corresponding components. The bracket’s dimensions and installation position strictly adhere to the original manufacturer’s design standards. Installation requires no modifications to the equipment structure; simply tighten the fixing bolts according to the specified steps to complete the assembly. This ensures the coordination between the supported components and the overall machine system, reducing installation and commissioning time and helping the equipment quickly return to operational status.

The 318306805 bracket demonstrates excellent durability and environmental adaptability. The surface undergoes sandblasting and rust removal followed by multi-layer anti-corrosion coating, forming a dense protective coating with a salt spray resistance exceeding 1000 hours. This effectively resists corrosion from harsh environments such as high dust levels in mines, high humidity in wetlands, and high salt spray in coastal areas, ensuring long-term rust and corrosion resistance. All welds undergo non-destructive testing to ensure the absence of defects such as incomplete welds and slag inclusions, fundamentally eliminating the risk of structural fracture and guaranteeing the long-term reliable operation of the support.

In terms of structural details, the edges of the support are ground and blunted to avoid the risk of sharp corners causing scratches to operators or other parts, improving safety. Simultaneously, the support has reserved space for reasonable wiring and conduit routing, ensuring that it will not interfere with the layout of pipelines and wiring harnesses after installation, providing convenience for future maintenance and repair.

When you need to replace the support for your XCMG XE2000 excavator, choosing the original product with part number 318306805 means choosing reliable component support. With its robust load-bearing capacity, sturdy structural design, superior corrosion resistance, and precise adaptability, it ensures the stable operation of the excavator’s core components, reducing downtime caused by support issues. This allows you to operate with peace of mind in various complex construction scenarios, enabling you to fully accelerate project progress.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

318306873 Engine mounting assembly XCMG XE2000 excavator spare parts

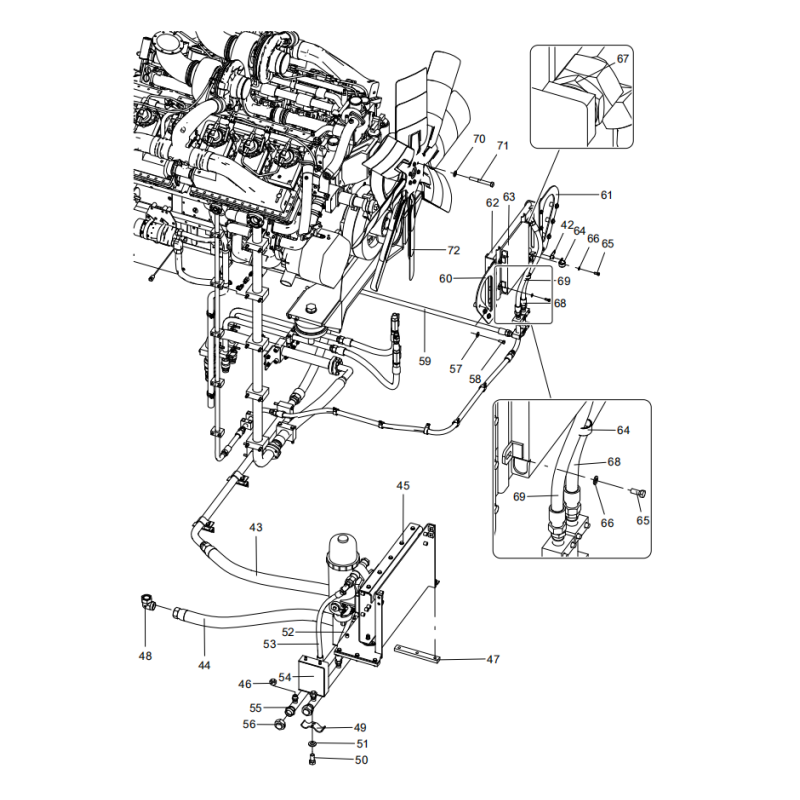

42 318306805 1 BRACKET

43 800171719 1 DIESEL PIPE

44 800166878 1 DIESEL PIPE

45 318300827 1 FUEL FILTER INSTALLATION

46 803177599 4 PLUG

47 318307383 2 PAD

48 803301445 2 CONNECTOR

49 329900503 2 PIPE CLIP

50 805046469 28 BOLT M12×25 GB/T5783-2000

51 805338281 28 WASHER 12 GB/T97.1-2002

52 800175192 1 DIESEL PIPE

53 803419817 1 HOSE ASS’Y

54 318800855 2 STEEL PIPE BRACKETA

55 318800843 2 OIL INLET STEEL PIPEA

56 803173882 2 PLUG

57 329900298 6 THICKENED LARGE WASHER

58 329901414 6 BOLT

59 803419820 1 HOSE ASS’Y

60 318306785 1 BRACKET

61 318306786 1 BRACKET

62 318300819 1 BRACKET

63 800152621 1 FUEL RADIATOR

64 803697900 8 IMPREGNATED HOOP

65 805011330 4 BOLT M10×25 GB/T5783-2000

66 805338279 4 WASHER 10 GB/T97.1-2002

67 800151146 2 CONNECTOR

68 800175156 1 DIESEL PIPE

69 800175154 1 DIESEL PIPE

70 318300796 6 WASHER

71 318300795 6 BOLT

72 800157257 1 FANS