Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800159518 hose XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Hose (Part No. 800159518): A Flexible Transmission Hub for Heavy-Duty Systems

In the global heavy-duty construction field of mining engineering, the XCMG XE2000 excavator, with its 192-ton operating weight, powerful 810kW engine, and large bucket capacity of 10-14m³, has become the “efficiency core” of mining operations. From the high-altitude hard rock mining areas of the Democratic Republic of Congo to the open-pit coal mines of Australia, it consistently conquers extreme working conditions with its stable and efficient performance. Within its complex fluid transmission network, the hose (part no. 800159518), acting as a “flexible transmission hub,” is a key component connecting rigid pipelines and moving parts, providing a flexible and reliable solution for high-pressure media transmission.

I. Core Responsibility of Flexible Media Transmission

High-Pressure Dynamic Media Conduction: The XE2000’s hydraulic system operates at pressures up to 35MPa. During dynamic operations such as boom lifting and slewing, the hose (800159518) undertakes the task of transmitting high-pressure hydraulic oil between moving parts. Its excellent flexibility allows for free expansion and contraction with component movement, maintaining unobstructed media transmission across the entire operating range, with pressure loss controlled within 2.8%. In the intense movements of hard rock excavation, it can stably withstand pulse pressure impacts and high-frequency vibrations, preventing pipe breakage due to rigid connections and ensuring continuous power output of the hydraulic system.

Multi-Scenario Adaptability: This hose is made of oil- and temperature-resistant composite materials, suitable for transmitting not only hydraulic oil but also coolant, lubricating oil, and other media. It maintains good flexibility and sealing performance even in extreme temperature environments ranging from -30℃ to 100℃, without hardening or cracking at low temperatures or aging and leaking at high temperatures. In the high-dust, high-humidity environment of mines, the outer wear-resistant protective layer effectively resists sand and gravel abrasion and moisture erosion, ensuring long-term stable transmission.

II. Superior Performance Designed for Heavy-Duty Operations

High-Strength Structure and Precision Manufacturing: To meet the heavy-duty requirements of the XE2000, the hose (800159518) adopts a multi-layer composite structure design: the inner layer is oil-resistant nitrile rubber, ensuring media compatibility; the middle layer is a high-strength steel wire braided reinforcement layer, with a burst pressure exceeding four times the working pressure (≥140MPa); the outer layer is wear-resistant and weather-resistant neoprene rubber, with a Shore hardness of 75±5A. The connector uses a crimp-type connection process, with crimping accuracy controlled within ±0.1mm, ensuring an integrated structure with the hose and eliminating the risk of leakage under high pressure. The overall bending radius is 20% smaller than ordinary hoses, making it suitable for installation in confined spaces. Dynamically Adaptive Optimized Design: XCMG engineers, through dynamic simulation testing, designed the optimal length and bending allowance for the hose, ensuring it maintains a reasonable stress state throughout the entire operating range of the equipment. The joint adopts a rotary design to reduce torsional stress; key components are equipped with wear-resistant protective sleeves to reduce frictional wear with other parts. This optimized design increases the hose’s dynamic fatigue life to over 1 million cycles, far exceeding industry standards.

III. Quality and Service Assurance Under Rigorous Testing

Comprehensive Performance Limit Testing: Every batch of hoses (800159518) undergoes multiple rigorous tests before leaving the factory: a water pressure burst test at 4 times the working pressure (30 minutes without rupture), a high and low temperature cycle test from -40℃ to 120℃ (600 cycles without cracking), a 1.5 million-cycle bending fatigue test (simulating 8 years of operating conditions), and an oil aging resistance test (immersion in hydraulic oil for 1000 hours without swelling). A series of stringent tests ensure the long-term reliability of the product under extreme operating conditions. Under the operational philosophy of “flexibility equals reliability” in mining construction, the XCMG XE2000 excavator hose (part number 800159518) provides reliable support for equipment in dynamic operating conditions with its superior flexible transmission performance. Choosing this original equipment manufacturer (OEM) custom hose not only reduces the risk of failure in moving parts connections but also improves the response speed and stability of the hydraulic system, continuously creating value for mining production. Let XCMG’s original quality become the flexible support for your heavy-duty construction.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

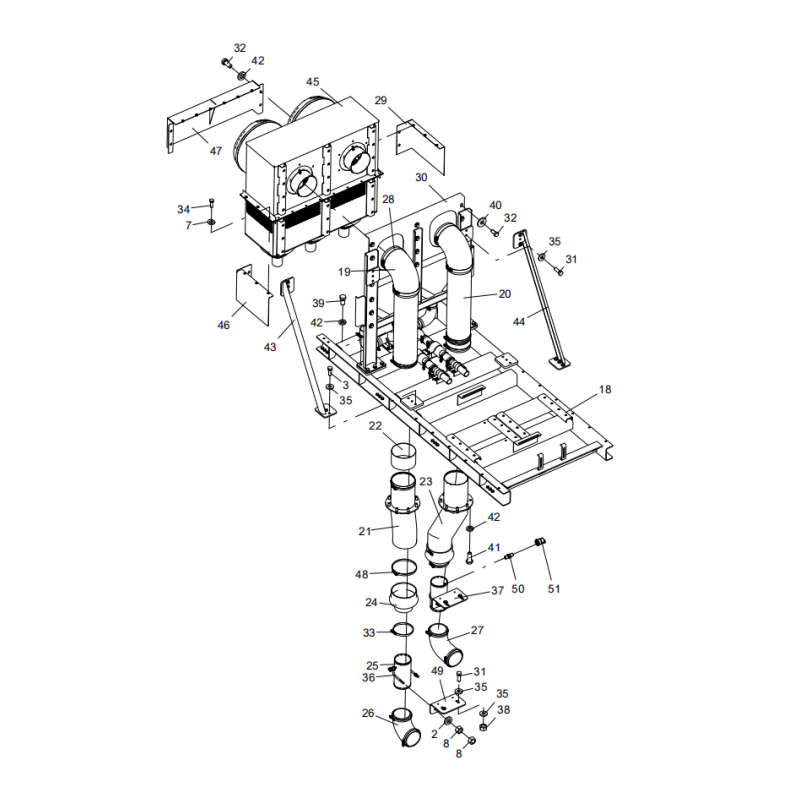

318302434 engine air intake system XCMG XE2000 excavator spare parts

18 318302435 1 BRACKET

19 800159567 2 HOSE

20 318306893 2 STEEL PIPE

21 318306895 1 INLET STEEL PIPE COMPONENT

22 800159518 2 HOSE

23 318306891 1 INLET STEEL PIPE ASSEMBLY

24 800152634 2 INTAKE FILTER PIPE

25 318302440 2 AIR INLET ASSEMBLY

26 800167479 1 INTAKE HOSE

27 800167478 1 INTAKE HOSE

28 800163870 4 HOOP

29 318302443 1 BRACKET

30 318600969 1 BRACKET

31 805006413 10 BOLT M12×35 GB/T5783-2000

32 318601034 23 BOLT

33 800164162 6 HOOP

34 805046416 10 BOLT M10×30 GB/T5783-2000

35 329900298 20 THICKENED LARGE WASHER

36 318302442 2 U-BOLT

37 318302441 1 BRACKET

38 805239270 4 NUT M12 GB/T6170-2000

39 805006417 12 BOLT M16×30 GB/T5783-2000

40 329900300 19 THICKENED LARGE WASHER

41 329901065 16 BOLT

42 329900304 32 THICKENED FLAT WASHER

43 318302438 1 BRACKET

44 318601026 1 BRACKET

45 800158698 1 FILTER OF AIR

46 318302445 1 BRACKET

47 318302444 1 BRACKET

48 800164160 6 HOOP

49 318306787 1 BRACKET

50 800105475 2 CONNECTOR