Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318301766 pipe clamp assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Pipe Clamp Assembly (Part No. 318301766): A System-Level Guardian of Pipeline Safety

In the global heavy-duty construction field of mining engineering, the XCMG XE2000 excavator, with its 192-ton operating weight, powerful 810kW engine, and ultra-large bucket capacity of 10-14m³, has become the “performance flagship” of mining operations. From the high-altitude hard rock mining areas of the Democratic Republic of Congo to the open-pit coal mines of Australia, it consistently conquers extreme working conditions with its stable and efficient performance. Within its intricate pipeline system, the pipe clamp assembly (part no. 318301766), as a “system-level solution” for pipeline fixing, is a core component ensuring the safe operation of critical pipelines such as hydraulic and fuel lines.

I. Bearing the Heavy Responsibility of Stabilizing Pipeline Clusters

Multi-Pipeline Coordinated Fixing: The XE2000’s hydraulic system includes multiple pipelines such as the main oil circuit, return oil circuit, and control oil circuit, simultaneously withstanding 35MPa high pressure and severe vibration during high-intensity operations. The pipe clamp assembly (318301766) adopts a modular design, achieving cluster fixation of pipelines of different diameters through adjustable clamping units. It can organize complex pipelines by functional zones, avoiding mutual friction or resonance between pipelines. In heavy-duty crushing operations after hard rock blasting, the equipment vibration amplitude is 2-3 times that of conventional working conditions. This assembly can disperse vibration stress through the overall rigid frame, preventing individual pipelines from breaking due to excessive local stress. Extreme Environment Protection: Designed for the harsh environments of mines, characterized by high dust, high humidity, and fluctuating temperatures, the pipe clamp assembly (318301766) employs differentiated fixing solutions for different pipelines. Hydraulic pipelines are equipped with high-strength metal clamps, fuel pipelines feature an added insulating and shock-absorbing pad, and cooling pipelines have pre-reserved heat dissipation space. This precise adaptation design ensures that within a temperature range of -30℃ to 50℃, the pipelines maintain a stable connection without affecting media transmission efficiency, while minimizing the impact of dust accumulation on pipeline heat dissipation.

II. Superior Performance Designed for Heavy-Duty Systems

High-Strength Materials and Precision Manufacturing: To meet the heavy-duty requirements of the XE2000, the main body of the pipe clamp assembly (318301766) is made of high-strength alloy steel plate by stamping, with a tensile strength exceeding 560MPa. Key connecting bolts utilize grade 8.8 high-strength fasteners. The inner side of the clamping arm is inlaid with an oil-resistant rubber buffer layer, ensuring both clamping firmness and preventing wear on the pipe surface. The rubber material has undergone 1000 hours of oil resistance testing without aging or deformation. After being treated with a zinc-nickel alloy plating, the surface can withstand more than 1000 hours of salt spray testing, providing long-term resistance to corrosion in high-humidity mining environments. Vibration and noise reduction structural optimization: XCMG engineers optimized the support point layout and elastic coefficient of the pipe clamp assembly through dynamic simulation analysis. The connection between the bracket and the machine body adopts an elastic damping structure, which can reduce the pipe vibration transmission rate by more than 40%. Buffer layers are set between multiple pipe clamping units to prevent the transmission of vibration between pipes, reducing the overall pipe system operating noise by 12%. This optimized design increases the fatigue life of the pipe clamp assembly to 1.2 million cycles, far exceeding industry standards.

III. Quality and Service Assurance Under Rigorous Testing

System-level Performance Verification: Every batch of pipe clamp components (318301766) undergoes comprehensive testing before leaving the factory: static load test at 1.5 times the rated load (no deformation for 60 minutes), 1 million cycles of random vibration test (simulating 8 years of working conditions), high and low temperature cycle test from -40℃ to 120℃ (no functional failure after 500 cycles), and oil corrosion resistance test (no component failure after 1000 hours of immersion in hydraulic oil). Rigorous testing ensures the long-term reliability of the product under extreme working conditions.

In mining construction, where “details determine reliability,” the XCMG XE2000 excavator pipe clamp component (part number 318301766) provides a systematic fixing solution to safeguard the safe operation of the pipeline system. Choosing this original equipment manufacturer (OEM) customized component not only reduces the risk of downtime due to pipeline failures but also extends the overall service life of the equipment, continuously creating value for mining production. Let XCMG’s original factory quality be your reliable guarantee for heavy-duty construction.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

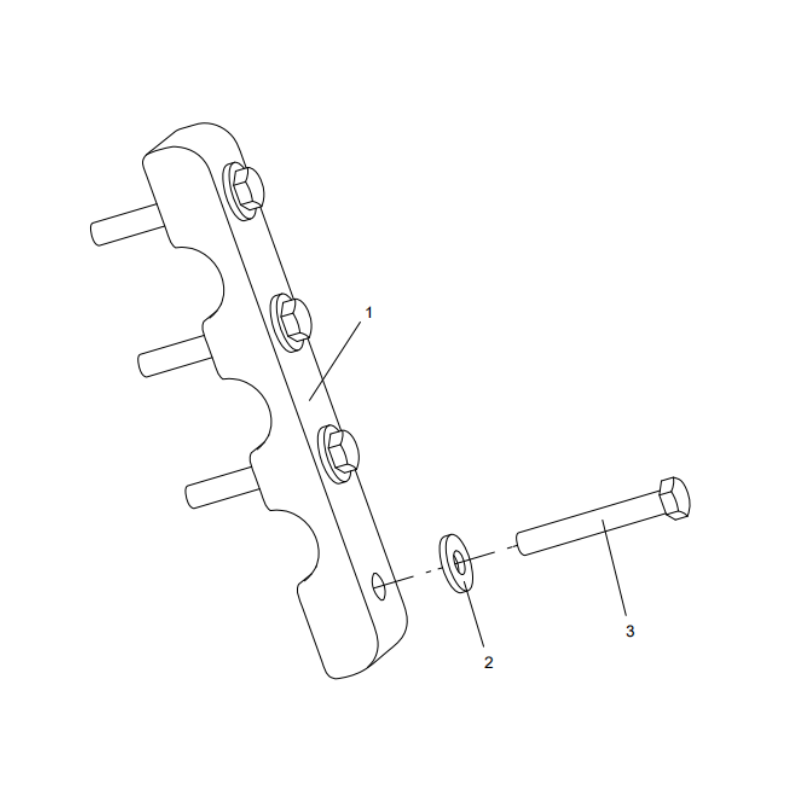

318301766 pipe clamp assembly XCMG XE2000 excavator spare parts

1 318301771 1 PIPE CLIP

2 329900297 4 THICKENED LARGE WASHER

3 805046622 4 BOLT M10×70 GB/T5782-2000