Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803379383 connector XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Connector (Part No. 803379383): The Safety Core of Heavy-Duty Connections

In the global heavy-duty construction field of mining engineering, the XCMG XE2000 excavator, with its 192-ton operating weight, powerful 810kW engine, and large bucket capacity of 10-14m³, has become the “performance leader” in mining operations. From the high-altitude hard rock mining areas of the Democratic Republic of Congo to the open-pit coal mines of Australia, it consistently handles various extreme working conditions with stable and efficient performance. Within its complex and precise mechanical system, the connector (part no. 803379383), as the “connecting bridge” between various core components, is a key component ensuring the safe and stable transmission of power and signal interaction.

I. Core Function of Supporting Multiple Connections

Safety Hub for Power Transmission: In high-intensity excavation operations, the XE2000’s hydraulic system, transmission system, and other core components require efficient power transmission, and the connector (803379383) is the critical node connecting these systems. It can stably withstand hydraulic system pressures up to 35MPa, ensuring lossless power transmission between the main pump, main valve, and actuator cylinders. In heavy-duty breaking operations following hard rock blasting, this connector can withstand continuous power impacts, preventing power interruptions due to connection failure and ensuring the continuity and efficiency of excavation operations.

Precise Signal and Control Interaction: In addition to power transmission, this connector also handles signal interaction between various control systems of the equipment. During automated operation, it accurately transmits sensor signals and control commands, ensuring the coordinated operation of the equipment’s intelligent monitoring and control systems. In environments prone to signal interference, such as high-altitude mining areas, its excellent anti-interference performance guarantees stable signal transmission, allowing operators to have a clear understanding of the equipment’s operating status and respond promptly to various changes in operating conditions.

II. Superior Performance Designed for Heavy-Duty Operations

High-Strength Materials and Precision Machining: To meet the heavy-duty requirements of the XE2000, the connector (803379383) is forged from high-strength alloy steel, achieving a tensile strength exceeding 800MPa, far surpassing the standards of ordinary engineering machinery connectors. Its connection interface undergoes precision machining, with tolerances controlled within ±0.03mm, ensuring a tight fit and eliminating the risk of leakage. After special wear-resistant and corrosion-resistant treatment, the surface not only resists dust and oil corrosion in the mining environment but also maintains stable performance in extreme temperatures ranging from -40℃ to 120℃.

Vibration-Resistant and Anti-Loss Structure: XCMG engineers designed a unique vibration-resistant and anti-loosening structure for this connector specifically for the severe vibration environment of mining operations. Through multiple locking devices and elastic buffer design, the impact of vibration on the connection points is effectively reduced, preventing loosening or detachment during high-frequency vibration operation of the equipment. Compared to traditional connectors, its vibration resistance is improved by over 40%, ensuring a reliable connection throughout the equipment’s full-range operation.

III. Quality and Service Guarantee Under Stringent Testing

Comprehensive Performance Limit Testing: Every batch of connectors (803379383) undergoes rigorous testing before leaving the factory: a pressure withstand test of 1.5 times the rated pressure (no leakage for 60 minutes), a vibration fatigue test of 1 million cycles (simulating 8 years of operating conditions), a high and low temperature cycle test from -40℃ to 120℃ (no abnormalities after 500 cycles), and a salt spray corrosion test (no rust after 1000 hours). This series of strict tests ensures the long-term reliability of the product under extreme operating conditions.

In the mining construction industry, where “safety first, efficiency paramount” is the guiding principle, the XCMG XE2000 excavator connector (part number 803379383) safeguards the safe and efficient operation of equipment with its superior connection performance. Choosing this original equipment manufacturer (OEM) custom connector not only reduces the risk of equipment failure but also improves the overall efficiency of mining construction, continuously creating value for your mining production. Let XCMG’s original quality be a reliable guarantee for your heavy-duty construction.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

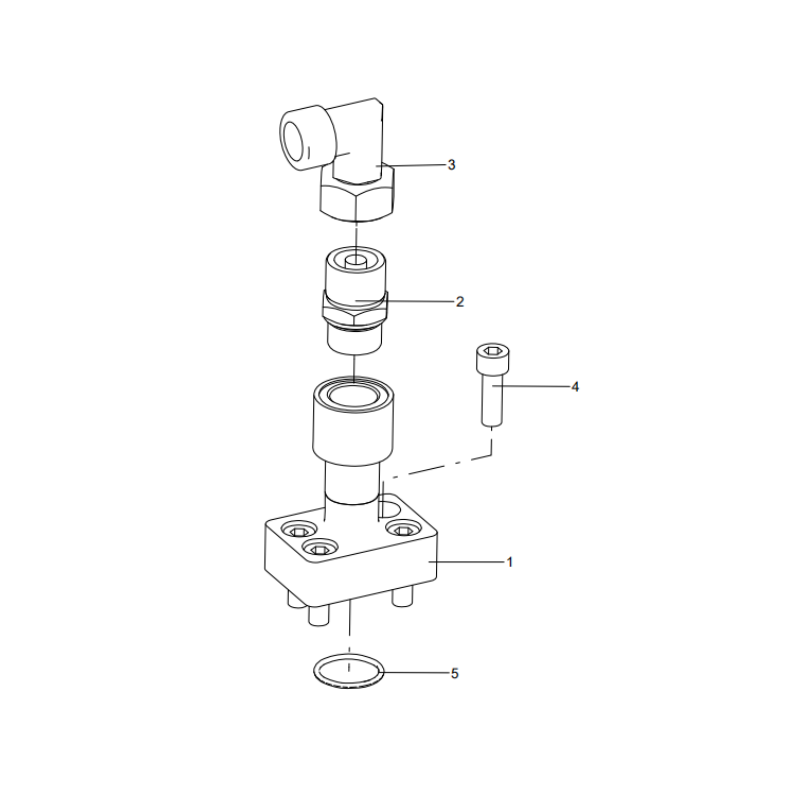

318307881 steel pipe assembly XCMG XE2000 excavator spare parts

1 318307921 1 WELDED STEEL PIPE

2 803103345 1 CONNECTOR

3 803379383 1 CONNECTOR

4 805047567 4 SCREW M10×30 GB/T70.1-2008

5 803192477 1 ORING 30×2.65 GB/T3452.1-2005