Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318810075 pipe clip XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Steel Pipe Assembly (Part No. 318810075): The Steel Artery of Heavy-Duty Power Transmission

On the harsh battlefields of global mining engineering, the XCMG XE2000 excavator, with its 192-ton operating weight, powerful 810kW engine, and ultra-large bucket capacity of 10-14m³, has become the “performance benchmark” for heavy-duty construction. From the high-altitude hard rock mining areas of the Democratic Republic of Congo to the open-pit coal mines of Australia, this equipment has consistently conquered extreme working conditions with its stable and efficient performance. Within its complex and precise mechanical system, the steel pipe assembly (part no. 318810075), as the “steel artery” of hydraulic and power transmission, is a core component ensuring the continuous output of powerful performance from the equipment.

I. The Power Transmission Hub Bearing Extreme Pressure

Key Channel of the High-Pressure Hydraulic System: The XE2000’s hydraulic system operates at pressures up to 35MPa. During high-intensity excavation operations, the steel pipe assembly (318810075) bears the heavy responsibility of transmitting high-pressure hydraulic oil between the main pump, main valve, and boom and stick cylinders. Its optimized pipe diameter design and smooth pipeline layout minimize hydraulic oil flow resistance, ensuring explosive force and responsiveness in excavation operations. In heavy-duty breaking operations after hard rock blasting, this assembly can stably withstand continuous high-pressure impacts, preventing equipment downtime due to pipeline rupture and ensuring construction continuity.

Multi-System Coordination Transmission Link: In addition to hydraulic transmission, this steel pipe assembly also integrates key pipeline functions such as fuel supply and coolant circulation. In extreme temperature environments ranging from -30℃ to 50℃, the assembly’s high and low temperature resistance ensures smooth fuel delivery at low temperatures and efficient coolant circulation at high temperatures, providing a fundamental guarantee for stable engine operation. In the high-humidity environment of the Indonesian rainforest mining area, its moisture-proof and corrosion-resistant design effectively prevents internal scaling and blockage of pipelines, ensuring smooth operation of multiple systems.

II. Superior Design Customized for Heavy-Duty Conditions

High-Strength Materials and Precision Manufacturing: To match the heavy-duty requirements of the XE2000, the steel pipe assembly (318810075) is made of high-strength seamless alloy steel pipe with a tensile strength exceeding 650MPa, far exceeding the standards of ordinary engineering machinery pipelines. Pipeline interfaces utilize precision forging and laser welding technology, controlling the flatness error of the sealing surface to within 0.02mm, completely eliminating the risk of leakage under high pressure. After multi-layer composite anti-corrosion treatment, the surface can withstand salt spray testing for over 1200 hours, providing long-term resistance to rust in the high-humidity, high-salinity coastal mining environment.

Optimized Layout for Overall Machine Adaptation: XCMG engineers, through 3D simulation and thousands of on-site working condition tests, tailored the layout of the steel pipe assembly for the XE2000. The piping cleverly avoids interference areas such as the boom and slewing mechanisms, and is fixed with specialized shock-absorbing brackets to reduce vibration and wear, extending the piping’s service life by over 60%. This high degree of adaptability to the overall machine structure ensures that the piping maintains a stable transmission state during full-range operation, avoiding malfunctions caused by bending and friction.

III. A Quality Assurance System Exceeding Industry Standards

Comprehensive Testing Under Extreme Conditions: Every batch of steel pipe components (318810075) undergoes four rigorous tests before leaving the factory: a water pressure burst test at 2.5 times the working pressure (60 minutes without leakage), a high and low temperature cyclic impact test from -40℃ to 120℃ (800 cycles without cracking), a 1.5 million-cycle vibration fatigue test (simulating 8 years of operating conditions), and a chemical corrosion resistance test (immersion in hydraulic oil and mining coolant for 300 hours without swelling or deformation). These stringent testing standards ensure the long-term reliability of the product under extreme operating conditions. In the high-intensity operations of mining construction where “time is money,” the XCMG XE2000 excavator steel pipe assembly (part number 318810075) provides a stable and reliable power transmission system with military-grade quality. Choosing this original equipment manufacturer (OEM) component not only reduces equipment failure rates but also extends the service life of core components, continuously creating value for mining production. Let XCMG’s OEM quality be your solid guarantee for heavy-duty construction.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

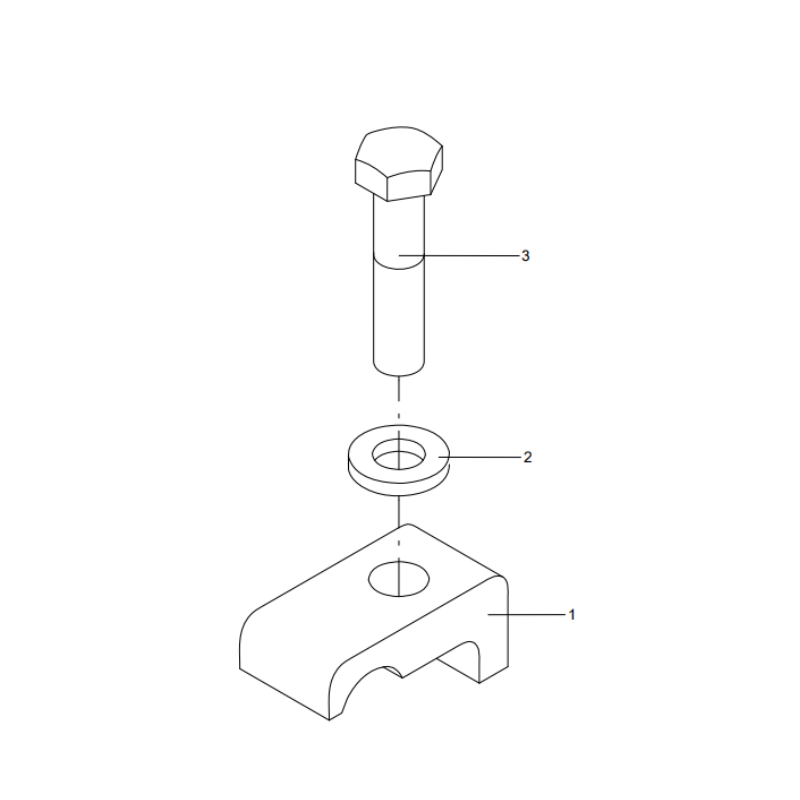

318809985 PIPE CLAMP ASSEMBLY

1 318810075 1 PIPE CLIP

2 329900302 1 THICKENED FLAT WASHER

3 805046772 1 BOLT M10×45 GB/T5782-2000