Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803195587 connector XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Impregnated Ring (Part No. 803195587): The Core of Sealing Protection Under Extreme Working Conditions

As a “juggernaut” in heavy-duty mining operations, the XCMG XE2000 excavator, with its 192-ton operating weight, powerful 810kW engine, and massive bucket capacity of 10-14m³, holds a significant position in the global mining market. From the high-altitude hard rock mines of the Democratic Republic of Congo to the humid rainforest mines of Indonesia, this equipment consistently meets various extreme challenges with outstanding stability. Within its sophisticated mechanical structure, the impregnated ring (part no. 803195587), as a key sealing component, acts like a “protective shield,” providing durable and reliable sealing protection for core components.

I. The Crucial Responsibility of Sealing Core Components

Leak Prevention Barrier for the Hydraulic System: The XE2000’s hydraulic system operates at pressures up to 35MPa. During high-intensity excavation operations, the sealing performance of hydraulic components directly impacts equipment efficiency. Impregnated rings (803195587) precisely fit the sealing grooves of key hydraulic components such as main pumps, main valves, and cylinders. The elastic sealing surface formed through a special impregnation process can tightly adhere to the sealing contact surface under high pressure, effectively preventing hydraulic oil leakage. In crushing operations after hard rock blasting, even when the equipment is subjected to severe vibration, the impregnated ring can maintain a stable seal, avoiding power loss due to hydraulic oil leakage. A guardian against dust and corrosion: Dust, slag, and corrosive media permeating the mining environment pose a serious threat to the metal components of equipment. Impregnated rings (803195587), with their excellent wear resistance and chemical corrosion resistance, form an effective isolation layer in the gaps of moving parts such as slewing bearings and travel drives, preventing contaminants from penetrating the bearing and gear meshing areas. In high-humidity, high-salinity environments such as coastal mining areas, its corrosion resistance can reduce the rust rate of components and extend the maintenance cycle by more than 30%.

II. Superior Performance Tailored for Heavy-Duty Operations

High-Strength Impregnating Material Formula: Designed specifically for the heavy-duty characteristics of the XE2000, this impregnating ring uses imported high-strength fiber substrate, impregnated and cured with a special resin. It achieves a Shore A hardness of 75±5 and a tensile strength ≥15MPa, far exceeding the standards of ordinary industrial seals. The material maintains stable elasticity within a temperature range of -40℃ to 120℃, adapting to extreme temperature variations from the Siberian permafrost to the edge of the Sahara Desert, ensuring sealing performance is unaffected by temperature fluctuations.

Precision-Made Structural Design: XCMG engineers replicated the precise dimensions of the XE2000 sealing groove using 3D scanning technology and manufactured the impregnating ring (803195587) using a compression molding process, ensuring its cross-sectional tolerance is controlled within ±0.05mm. The unique lip seal structure design creates dynamic sealing compensation during component movement, reducing frictional resistance and improving sealing reliability. Compared to traditional seals, its coefficient of friction is reduced by 20%, effectively reducing power loss and component wear.

III. Quality Assurance System Exceeding Industry Standards

Full-Dimensional Extreme Performance Testing: Every batch of impregnated rings (803195587) undergoes four rigorous tests: 1000-hour high-pressure sealing test (no leakage under 35MPa pressure), 5000 cycles of thermal cycling (-40℃ to 120℃), 100,000 cycles of dynamic friction testing (simulating a 5-year service life), and chemical corrosion resistance test (immersion in hydraulic oil and mining coolant for 200 hours without swelling or deformation). These stringent testing standards ensure the long-term reliability of the product under extreme operating conditions.

In the high-intensity work rhythm of mining construction, where “downtime equals loss,” the XCMG XE2000 excavator impregnated ring (part number 803195587) provides military-grade sealing performance to safeguard the core components of the equipment. Choosing this original factory-customized impregnated ring not only reduces equipment failure rates but also extends the service life of core components, continuously creating value for mining production. Let XCMG’s original factory quality be your reliable support for heavy-duty construction.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

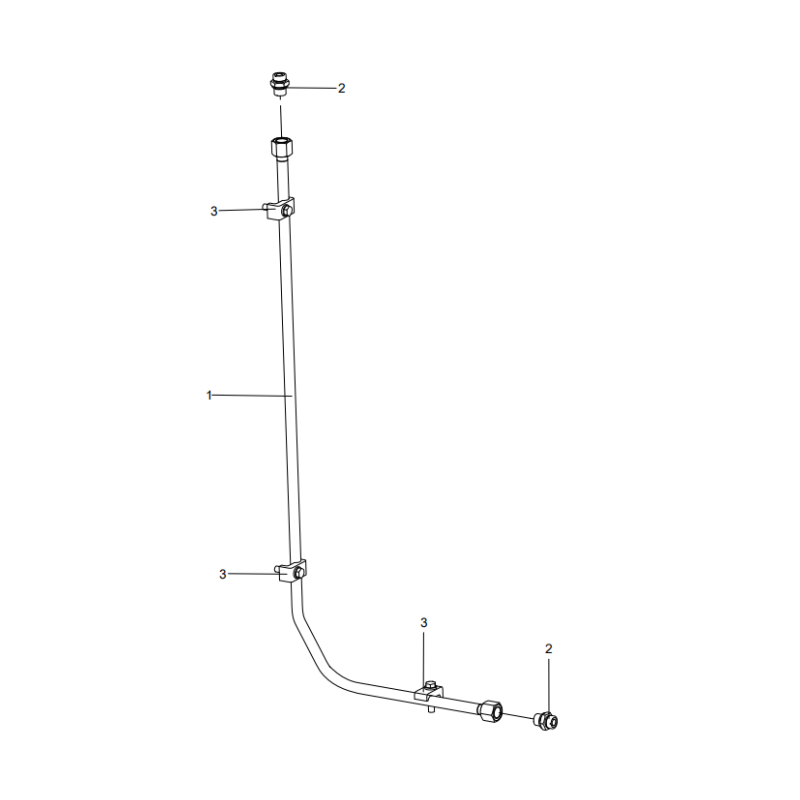

318307852 steel pipe assembly XCMG XE2000 excavator spare parts

1 318307863 1 WELDED STEEL PIPE

2 803195587 2 CONNECTOR

3 318809985 3 PIPE CLAMP ASSEMBLY