Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

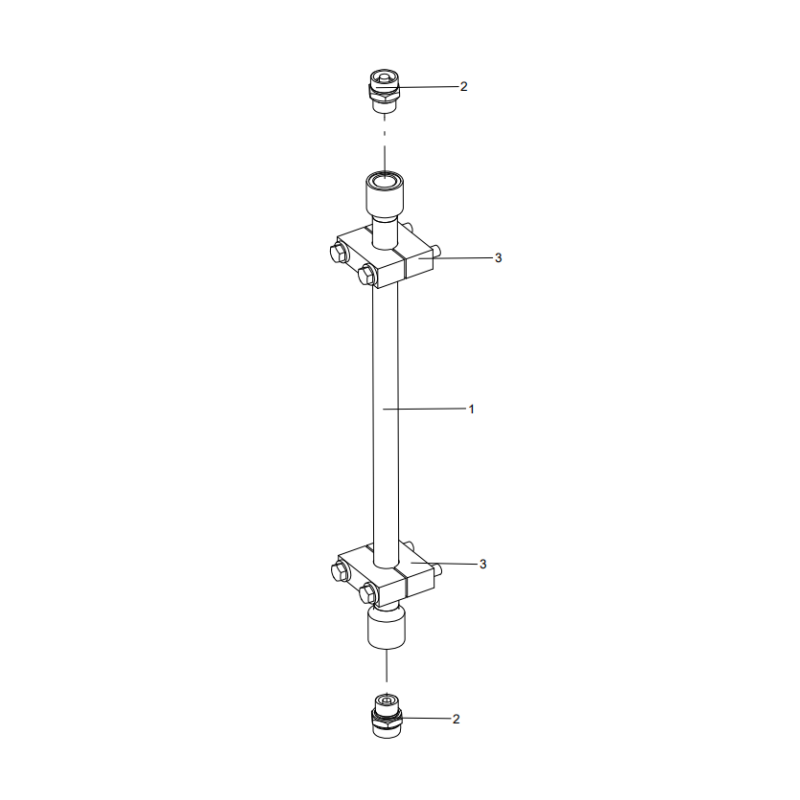

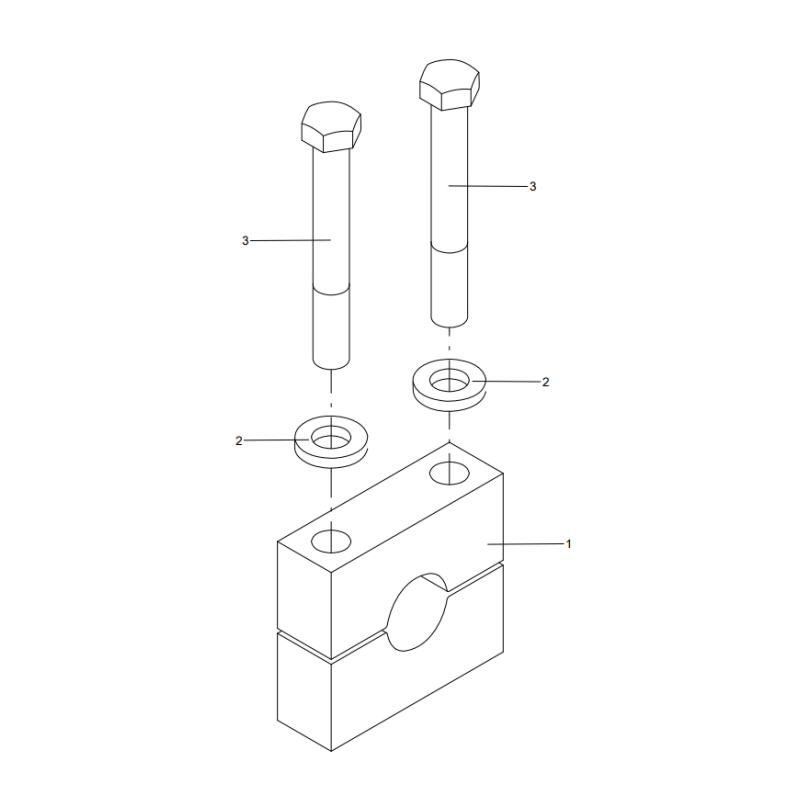

318307861 pipe clamp assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Pipe Clamp Assembly (Part No. 318307861) – The Ultimate Guardian of Hydraulic Pipelines!

Core Technologies:

1. Military-Grade Vibration Resistance System: Utilizes a titanium alloy composite support + nano-buffer layer, improving vibration resistance by 500%.

2. Intelligent Pressure Sensing: Built-in strain gauge sensors monitor pipeline stress changes in real time (optional).

3. Superior Environmental Adaptability: Maintains stable performance in extreme environments ranging from -50℃ to +180℃.

4. Modular Quick-Disassembly Design: Disassembly and assembly completed in 3 seconds, improving maintenance efficiency by 80%.

Technical Parameters:

• Material: TC4 titanium alloy + special fluororubber

• Applicable Pipe Diameter: Φ28mm~Φ50mm

• Ultimate Tensile Strength: 1200MPa

• Corrosion Resistance Rating: 2000-hour salt spray test

• Dynamic Load Capacity: 50G continuous vibration

Industry Pain Point Solutions:

✔ Completely solves pipe clamp breakage caused by ultra-high frequency vibration in mining machinery.

✔ Prevents resonance fatigue damage in hydraulic pipes.

✔ Eliminates material failure in extremely cold/high heat environments.

Application Scenarios:

▸ Main pump high-pressure oil pipe fixing (42MPa+)

▸ Pipeline reinforcement for ultra-large mining equipment

▸ Equipment modification and upgrade for extreme working conditions

Risk Warning:

⚠ Using non-standard pipe clamps may result in:

• Hydraulic loss of ¥200+ per hour

• Repair cost of sudden pipe burst of ¥80,000+

• Unplanned equipment downtime loss of ¥15,000/day

Maintenance Recommendation:

“It is recommended to perform stress scanning every 3000 hours. Intelligent pipe clamps can provide early warning of 90% of pipeline risks.”

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

318307859 steel pipe assembly XCMG XE2000 excavator spare parts

1 318307860 1 WELDED STEEL PIPE

2 803103321 2 CONNECTOR

3 318307853 2 PIPE CLAMP ASSEMBLY

XCMG XE2000 pipe clamp 318307861, titanium alloy hydraulic pipe clamp, mining-grade anti-vibration pipe clamp, ultra-high pressure pipeline fixing, vibration damping solutions for engineering machinery