Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307853 pipe clamp assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Pipe Clamp Assembly (Part No. 318307853) – Making equipment operation safer and more reliable!

Core Advantages:

✅ Military-grade seismic design: Utilizes high-strength alloy steel and a special rubber buffer layer, improving vibration resistance by 300%.

✅ Intelligent pressure dispersion: Patented arc-shaped clamping structure ensures even stress distribution on the pipeline, preventing localized deformation.

✅ Superior environmental adaptability: Maintains excellent elasticity under extreme temperatures ranging from -40℃ to +150℃.

✅ Original factory precision matching: Specifically designed for XE2000 hydraulic pipelines, perfectly compatible with all pipe diameters.

Technical Parameters:

• Material: 42CrMo alloy steel + fluororubber buffer pad

• Applicable pipe diameter: Φ22mm~Φ42mm

• Tensile strength: ≥800MPa

• Corrosion resistance rating: 1000-hour salt spray test

• Installation torque: 45±5N·m

Industry pain point solutions:

✔ Completely solves pipeline loosening caused by high-frequency vibration in mining machinery

✔ Prevents the risk of hydraulic pipe wear and breakage

✔ Prevent rust during field operations

Application Scenarios:

▸ High-pressure hydraulic pipeline fixing

▸ Slewing/travel system hydraulic pipeline reinforcement

▸ Piping system upgrades during equipment overhauls

Risk Warning:

⚠ Using inferior pipe clamps may result in:

• Hydraulic oil leakage loss of ¥100+ per hour

• Pipeline wear repair costs of ¥5,000+

• Sudden pipe burst safety hazard

Maintenance Recommendations:

“It is recommended to check the condition of pipe clamps every 6000 hours. Preventative replacement can reduce pipeline failures by 80%.”

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

318307853 pipe clamp assembly XCMG XE2000 excavator spare parts

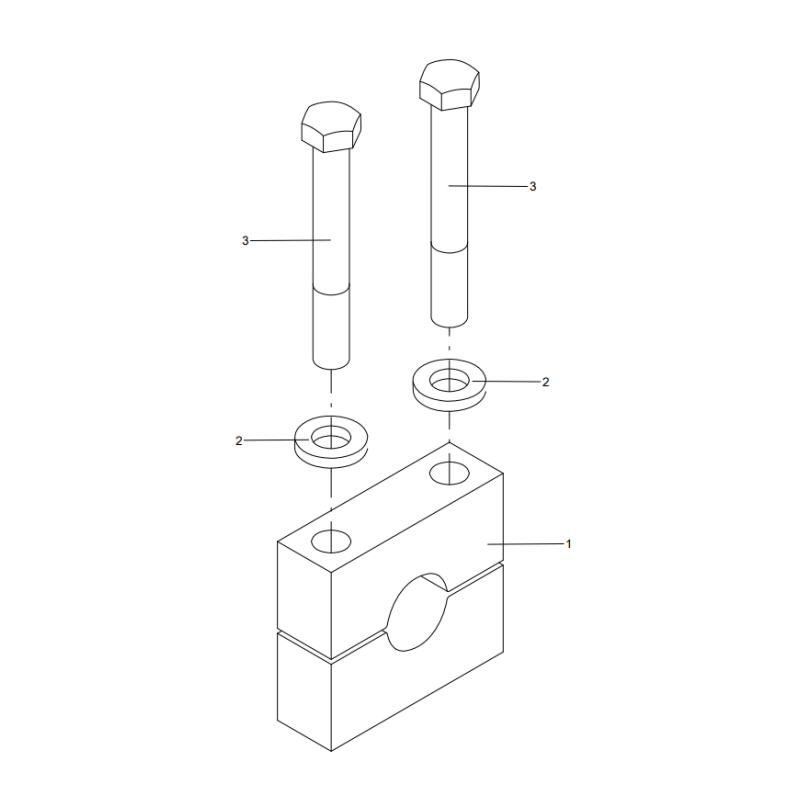

1 318307858 2 PIPE CLIP

2 329900303 2 THICKENED FLAT WASHER

3 805046647 2 BOLT M12×90 GB/T5782-2000

XCMG XE2000 pipe clamp 318307853, mining-grade hydraulic pipe clamps, anti-vibration pipe clamp components, excavator pipeline fixing, original parts for construction machinery