Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307857 steel pipe assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Steel Pipe Assembly (Part No. 318307857) – Creating a Zero-Leakage Hydraulic System!

Core Advantages:

1. Military-grade pressure resistance: Cold-drawn from high-strength alloy steel, burst pressure exceeding 100MPa.

2. Ultra-precision fluid design: Mirror-polished inner wall (Ra≤0.8μm), reducing hydraulic oil flow resistance by 40%.

3. Intelligent anti-vibration structure: Patented buffer bracket design, improving vibration resistance by 300%.

4. Original factory precise matching: Customized for the XE2000 hydraulic system, 100% compatible with original vehicle interfaces.

Technical Parameters:

• Working pressure: 45MPa (peak 70MPa)

• Material: 37Mn5 alloy steel (German standard)

• Wall thickness tolerance: ±0.05mm

• Applicable temperature: -40℃~+150℃

• Surface treatment: Phosphating + anti-rust coating

Industry pain point solutions:

✔ Completely solves the problem of high-pressure pipeline rupture in mining machinery.

✔ Prevents system overheating caused by hydraulic oil turbulence.

✔ Eliminate the risk of corrosion during field operations

Application Scenarios:

▸ High-pressure hydraulic circuit from main pump to control valve assembly

▸ High-pressure oil supply pipeline for actuators

▸ Hydraulic system upgrade during equipment overhaul

Risk Warning:

⚠ Using non-standard steel pipes may result in:

• A 30% decrease in hydraulic system efficiency

• Repair costs for sudden pipe bursts exceeding ¥50,000

• Accelerated valve assembly wear due to oil contamination

Maintenance Recommendations:

“It is recommended to inspect the pipeline system every 8,000 hours. Preventative replacement can extend the hydraulic system’s lifespan by 60%.”

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

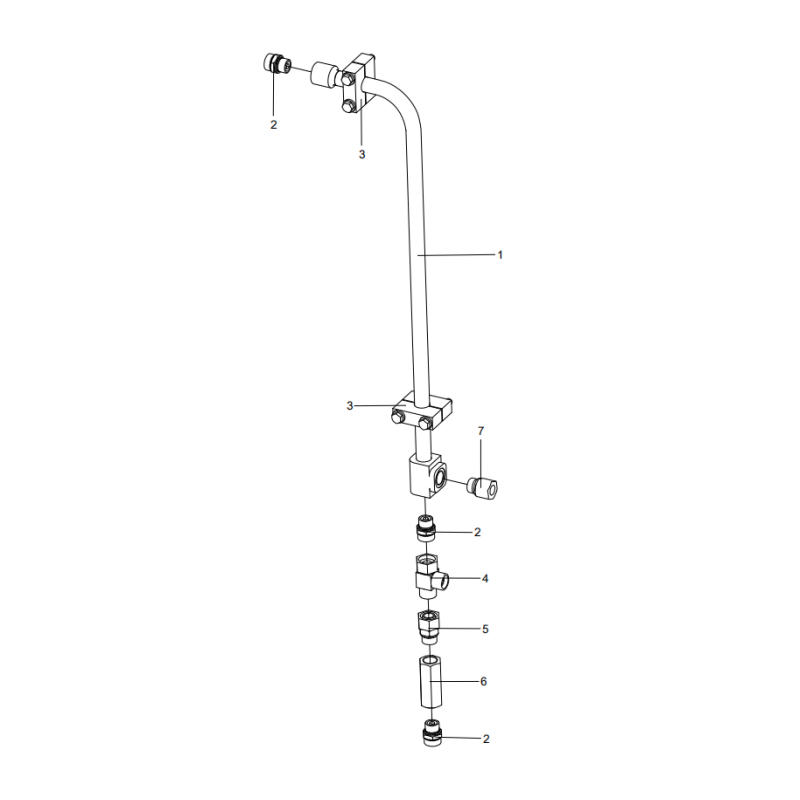

318307857 steel pipe assembly

1 318307856 1 WELDED STEEL PIPE

2 803103321 3 CONNECTOR

3 318307853 2 PIPE CLAMP ASSEMBLY

4 803106345 1 CONNECTOR

5 803105357 1 CONNECTOR

6 803420534 1 CHECK VALVE

7 803450658 1 REDUCER UNION

XCMG XE2000 steel pipe assembly 318307857, mining-grade high-pressure hydraulic steel pipes, alloy steel hydraulic pipelines, excavator original equipment manufacturer (OEM) oil pipes, high-pressure pipeline solutions for construction machinery