Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

860172287 o-ring XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 excavator O-rings (part number 860172287) – Protecting every critical connection in the hydraulic system!

Core Technologies:

1. Aerospace-grade Sealing Material: Utilizes fluororubber (FKM), improving oil resistance and high-temperature resistance by 300%.

2. Ultra-precise Dimensional Tolerance: 0.01mm-level machining accuracy ensures 100% sealing performance.

3. Intelligent Memory Structure: Maintains perfect resilience under dynamic operating conditions.

4. Extreme Environment Adaptability: Stable performance under operating conditions from -50℃ to +200℃.

Technical Parameters:

• Material: Imported fluororubber (DuPont™ Viton® grade)

• Hardness: 75±2 Shore A

• Tensile Strength: ≥18MPa

• Compression Set: ≤15% (200℃×72h)

• Applicable Media: Hydraulic oil/gear oil/lubricating oil

Industry Pain Point Solutions:

✔ Completely solves leakage problems in high-pressure hydraulic systems

✔ Prevents oil contamination caused by seal aging

✔ Eliminates seal failure under extreme temperature differences

Application Scenarios:

▸ Hydraulic Cylinder Piston Seal

▸ Multi-way Valve Assembly Interface Seal

▸ Pump/Motor End Cover Seal

Risk Warning:

⚠ Using non-standard seals may result in:

• 0.5-1L hydraulic oil leakage per hour

• 10-15% system pressure loss

• Repair costs for seal failure exceeding ¥8,000

Maintenance Recommendation:

“It is recommended to inspect and replace seals every 6000 hours. Preventative maintenance can reduce hydraulic leakage failures by 70%.”

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

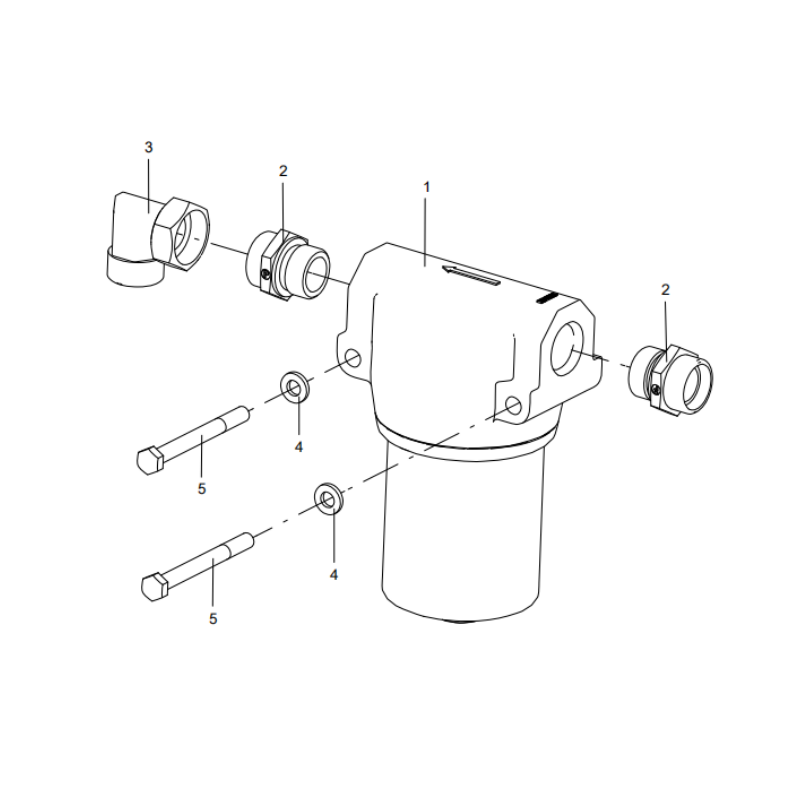

803389540 GEAR OIL FILTER ASSEMBLY

1 803399832 1 FILTER ELEMENT

2 860172287 1 ORING

3 860172284 1 HOLD WASHER