Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803171706 connector XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Connector 803171706: A Highly Efficient and Stable Hub for System Connections

In the complex system of the XCMG XE2000 large excavator, the connector (part number: 803171706) is a core component for achieving precise docking and efficient transmission of key systems such as hydraulics and electrical systems. It acts as the “intelligent interface hub” within the equipment, ensuring stable and smooth media delivery and signal transmission, providing a solid connection guarantee for the coordinated operation of the XE2000 during high-intensity operations.

Original Factory Precise Fit, Seamless Installation

Connector 803171706 is an original factory accessory exclusively developed by XCMG for the XE2000 excavator. Its design is entirely based on the connection requirements and structural parameters of the machine system. Through high-precision laser mapping and 3D modeling technology, key details such as the connector’s interface size, mating angle, pin distribution, and fixing structure are precisely controlled to ensure a “zero-gap” fit with the corresponding pipelines and cables. Whether it’s system integration during new machine assembly or component replacement during later maintenance, no additional adjustments or modifications are needed to the connection points, achieving seamless “plug-and-play” integration. This high degree of adaptability not only reduces installation difficulty and saves labor costs but also prevents problems such as loose connections, media leakage, or poor signal transmission caused by dimensional deviations from the outset.

Stable transmission design ensures efficient system operation

During operation, the XE2000 excavator has extremely high requirements for the sealing of hydraulic media transmission and the stability of electrical signal transmission. Connector 803171706 adopts a multi-seal and anti-interference design. The hydraulic interface is equipped with high-quality oil-resistant seals, forming a reliable sealing interface through precise structural fit, effectively preventing leakage of hydraulic oil, coolant, and other media, maintaining excellent sealing performance even under high-pressure conditions. For the electrical connection, a high-conductivity alloy pin and multi-layer shielding design are used to reduce signal attenuation and electromagnetic interference during transmission, ensuring accurate transmission of control commands and sensor data. Meanwhile, the connector is equipped with an anti-loosening locking device, which can firmly lock the mating state under severe equipment vibration or drastic changes in ambient temperature, preventing connection interruption due to bumps and ensuring the continuous and efficient operation of hydraulic, electrical, and other systems.

High-strength materials ensure superior durability

XCMG maintains strict quality control over the 803171706 connector throughout the entire production process, committed to creating durable components suitable for harsh working conditions. The shell is made of a combination of high-strength engineering plastics and zinc alloy materials, possessing excellent impact resistance, corrosion resistance, and high-temperature resistance, capable of withstanding impacts from gravel, oil erosion, and temperature fluctuations in the working environment. Internal core components are reinforced, and the pins are gold-plated to improve conductivity and wear resistance, maintaining stable performance even after thousands of mating cycles. The connector surface undergoes special anti-corrosion treatment, achieving a salt spray resistance of over 500 hours, effectively resisting corrosion from harsh environments such as humidity, dust, and acids/alkalis. Every connector undergoes rigorous testing before leaving the factory, including sealing tests, insertion and extraction force tests, vibration resistance tests, and high and low temperature cycle tests, to ensure it is free of quality defects and provides users with durable and reliable connection protection.

Choosing the XCMG XE2000 excavator connector 803171706 means choosing an efficient and stable “connection hub” for your equipment system. With its original factory precision fit, superior transmission performance, and reliable durability, it safeguards the XE2000 system operation in complex working conditions such as mining and infrastructure projects, reducing downtime caused by connection problems, allowing equipment to operate continuously and efficiently, and facilitating the smooth progress of projects.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

318307854 transfer-box independent radiator pipe XCMG XE2000 excavator spare parts

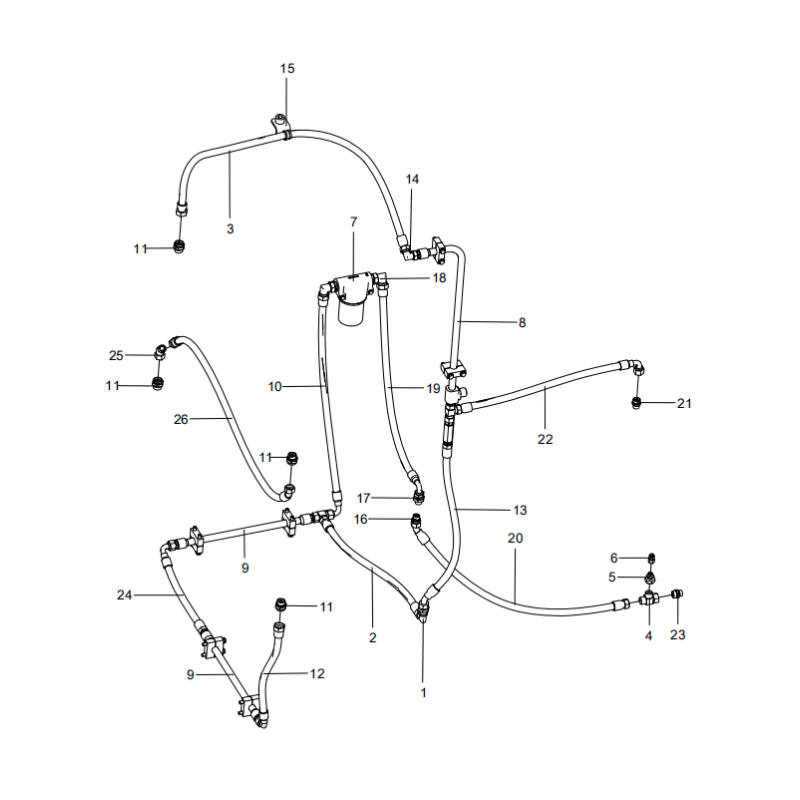

1 803171706 1 CONNECTOR

2 803403278 1 HOSE ASS’Y

3 804414218 1 HOSE ASS’Y

4 803106345 2 CONNECTOR

5 803174506 1 CONNECTOR

6 803110618 1 CONNECTOR

7 318307855 1 GEAR OIL FILTER ASSEMBLY

8 318307857 1 STEEL PIPE ASSEMBLY

9 318307859 2 STEEL PIPE ASSEMBLY

10 804414283 1 HOSE ASS’Y

11 803268721 4 CONNECTOR

12 804414281 1 HOSE ASS’Y

13 803170705 1 HOSE ASS’Y

14 803173684 1 CONNECTOR

15 318307861 1 PIPE CLAMP ASSEMBLY

16 803107270 1 CONNECTOR

17 803181866 1 CONNECTOR NON-STANDARD

18 803103798 1 CONNECTOR

19 803418136 1 HOSE ASS’Y

20 804414282 1 HOSE ASS’Y

21 803103321 1 CONNECTOR

22 803170957 1 HOSE ASS’Y

23 803163744 1 CONNECTOR

24 803075373 1 HOSE ASS’Y

25 803405660 1 CONNECTOR

26 803433439 1 HOSE ASS’Y