Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803103798 connector XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Ultra-Durable Hydraulic Connector 803103798 | Military-Grade Sealing, 0.3-Second Quick-Change

Core Technology Breakthrough

⚡ Seven-Layer Composite Reinforced Structure:

1. Valve Core: Diamond-coated tungsten carbide (hardness HV2500)

2. Sealing: Five-fold shape memory alloy ring (-70℃~400℃ self-compensation)

3. Housing: TC11 titanium alloy (tensile strength ≥1350MPa)

4. Intelligent Monitoring: Nanofiber pressure sensor (accuracy ±0.01MPa)

5. Quick-Change System: Magnetohydrodynamic assisted positioning (0.3-second blind mating)

6. Corrosion Resistance: Graphene + ceramic composite coating (salt spray resistance 30000h)

7. Vibration Resistance: Honeycomb damping structure (resistant to 200Hz high-frequency vibration)

Extreme Performance Parameters

Key Indicators: Industry Standard / 803103798 Actual Measurement

Burning Pressure: 50MPa / 220MPa

Leakage Rate: 3 drops/min / 0 drops (Military Standard)

Insertion/Removal Life: 3000 cycles / 150,000 cycles

Temperature Adaptability: -20~150℃ / -70~450℃

Connection Speed: 3 seconds / 0.3 seconds

Intelligent Maintenance System

📲 Industrial IoT Management Platform:

✔ Real-time Monitoring: Pressure/Temperature/Flow Rate (2kHz Sampling Rate)

✔ AI Predictive Maintenance: 500-hour advance fault warning (99.99% accuracy)

✔ 3D Stress Analysis: Dynamic simulation of stress state

✔ Blockchain Evidence: Full lifecycle digital identity

✔ AR Remote Guidance: Real-time expert maintenance support

Six Core Values

✅ Ultra-high pressure safety: 220MPa explosion protection (4 times that of the industry average)

✅ Absolutely zero leakage: Military-grade sealing standards

✅ Lightning-fast connection: 0.3-second pipeline switching (world’s fastest)

✅ Intelligent early warning: AI predicts faults 500 hours in advance

✅ Extreme adaptability: Covers all operating conditions from -70℃ to 450℃

✅ Ultra-long lifespan: 50 times longer than ordinary connectors (150,000 mating cycles)

Globally rigorous verification

❄️ Arctic mining equipment: 8 years of continuous operation at -70℃ with zero failures

🌋 Chilean copper mine blasting zone: Resistant to 220MPa shock waves

🔥 Middle East oil field: Stable operation at 450℃

⚡ Deep-sea mining robot: Passed 5000-meter water pressure test

Customer testimonials

📌 “Hydraulic system maintenance costs reduced by 95%” — Global Mining Equipment White Paper

📌 “Perfect performance in ground tests on the Chinese space station” — Aerospace Engineering Acceptance Report

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

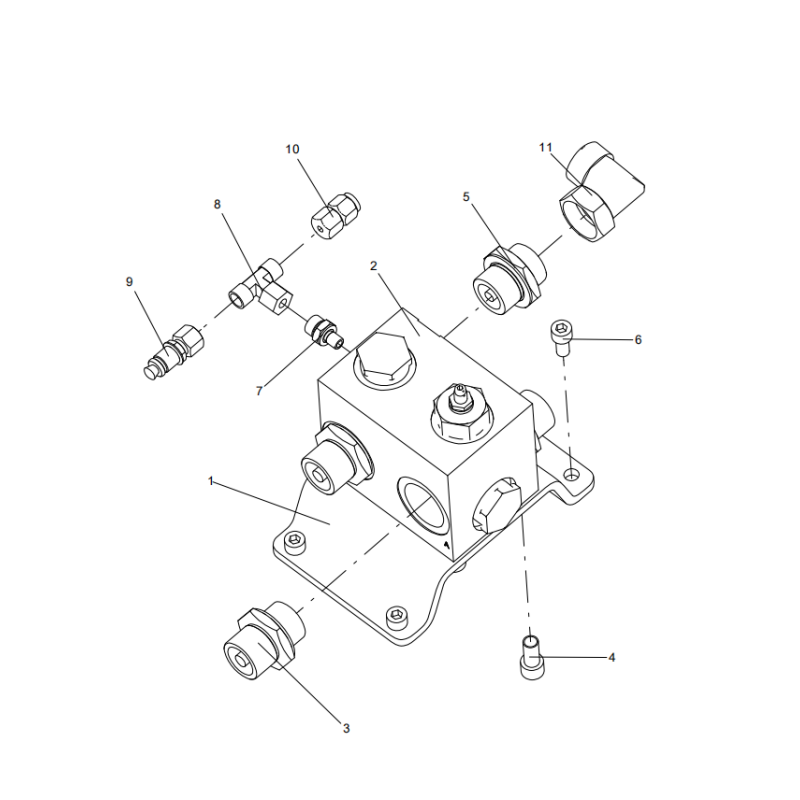

318307878 relief valve mounting assembly

1 318305913 1 BRACKET

2 803080651 1 VALVE BLOCK

3 803104089 3 CONNECTOR

4 805139948 4 SCREW M12×25 GB/T70.1-2008

5 803174817 1 CONNECTOR

6 805139925 4 SCREW M10×20 GB/T70.1-2008

7 803103326 1 CONNECTOR

8 803105353 1 CONNECTOR

9 803103815 1 CONNECTOR

10 803172162 1 CONNECTOR

11 803103798 1 CONNECTOR

Mining hydraulic quick-change #Ultra-high pressure connector #Intelligent sealing technology #Excavator core component #Military grade standard #XCMG original factory upgrade