Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803172162 connector XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Connector 803172162: The Stable Core of System Connection

In the precision system of the XCMG XE2000 large excavator, the connector (part number: 803172162) serves as the “bridge” for efficient connection of key systems such as hydraulics and electrical systems. With precise adaptability and reliable transmission performance, it ensures the coordinated operation of all components, providing a solid connection guarantee for the stable performance of the XE2000 during high-intensity operations.

Original Factory Exclusive Fit, Precise and Efficient Installation

Connector 803172162 is an original factory accessory custom-designed by XCMG for the XE2000 excavator. Its design is perfectly tailored to the system layout and connection requirements of the model. Utilizing high-precision 3D scanning and computer-aided design technology, the interface size, mating angle, and fixing structure are precisely determined to ensure a seamless match with the corresponding pipes and cables. Whether it’s system setup during new machine assembly or component replacement during later maintenance, no additional processing or adjustment is required at the connection points, achieving seamless “plug-and-play” integration. This high degree of adaptability not only reduces installation difficulty and shortens operation time but also prevents loose connections or functional failures caused by dimensional deviations from the outset.

Enhanced transmission design ensures smooth system operation

When operating under complex conditions, the XE2000 excavator has extremely high requirements for the sealing of media transmission and the stability of signal transmission. Connector 803172162 adopts a multi-seal structure design, equipped with high-quality seals at the interface. Through precise structural fit, a reliable sealing barrier is formed, effectively preventing leakage of media such as hydraulic oil and coolant, maintaining excellent sealing performance even under high-pressure environments. For the electrical connection, high-conductivity materials and anti-interference design are used to reduce signal loss and interference during transmission, ensuring accurate transmission of control commands and sensor data. Meanwhile, the connector is equipped with an anti-loosening locking device, which firmly secures the mating state during severe vibration or bumps, preventing connection interruption and ensuring the continuous and stable operation of the hydraulic and electrical systems.

Superior Materials and Craftsmanship, Outstanding Durability

XCMG maintains strict quality control over the 803172162 connector throughout the entire production process, committed to creating durable components suitable for harsh working conditions. The shell is made of high-strength alloy and engineering plastic composite, possessing excellent impact resistance, corrosion resistance, and high-temperature resistance, capable of withstanding impacts from gravel, oil erosion, and temperature changes in the working environment. Internal core components are reinforced, possessing excellent fatigue resistance, maintaining stable performance even after thousands of mating cycles. The connector surface undergoes professional anti-corrosion treatment, with a salt spray resistance of over 500 hours, effectively resisting corrosion from humid, dusty, and other harsh environments. Each connector undergoes multiple rigorous inspections before leaving the factory, including sealing tests, insertion and extraction force tests, and vibration tests, to ensure no quality defects and provide users with a long-lasting and reliable connection guarantee. Choosing the XCMG XE2000 excavator connector 803172162 means selecting a highly efficient and stable “connection hub” for your equipment system. With its original manufacturer-specific compatibility, enhanced transmission performance, and outstanding durability, it safeguards the XE2000’s system operation in complex scenarios such as mining and infrastructure construction, reducing downtime caused by connection problems and ensuring the equipment always operates at high efficiency, facilitating the smooth progress of projects.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

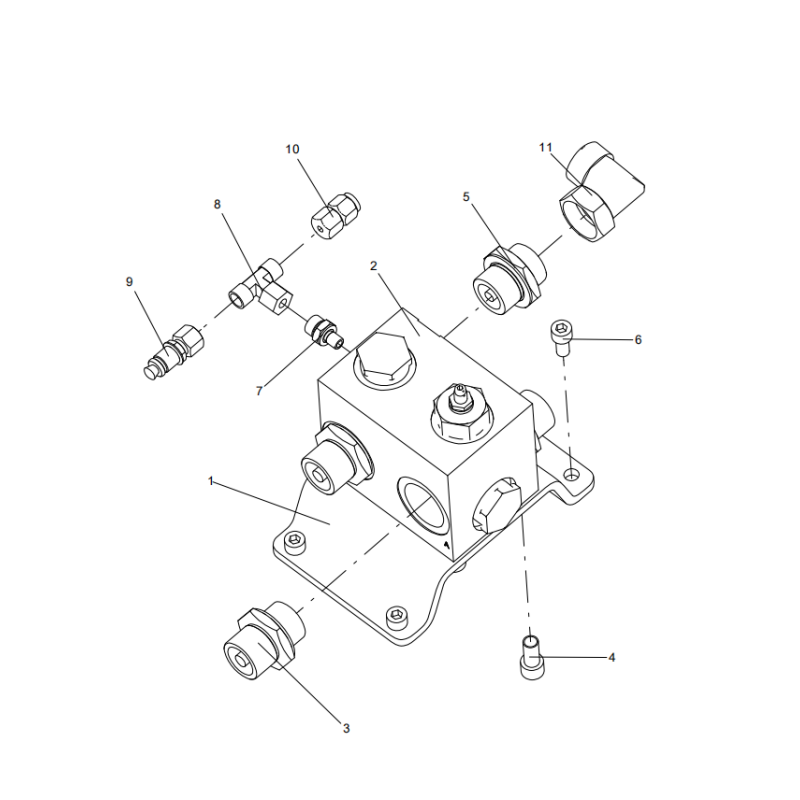

318307878 relief valve mounting assembly

1 318305913 1 BRACKET

2 803080651 1 VALVE BLOCK

3 803104089 3 CONNECTOR

4 805139948 4 SCREW M12×25 GB/T70.1-2008

5 803174817 1 CONNECTOR

6 805139925 4 SCREW M10×20 GB/T70.1-2008

7 803103326 1 CONNECTOR

8 803105353 1 CONNECTOR

9 803103815 1 CONNECTOR

10 803172162 1 CONNECTOR

11 803103798 1 CONNECTOR