Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307833 confluent block XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Manifold Block (318307833): The Precision Control Core of the Mining Hydraulic System

In key mining regions worldwide, such as Indonesia, the Democratic Republic of Congo, and Brazil, the XCMG XE2000 mining excavator, with its massive 12-cubic-meter bucket capacity and over 93% mobility, has become a core piece of equipment for efficient mining operations. Within the hydraulic system of this “mining giant,” the manifold block (part number 318307833) acts as the “central nervous system” of the hydraulic system, responsible for the distribution, merging, and pressure control of multiple hydraulic oil channels. It is a crucial hydraulic component ensuring precise and coordinated machine movements and efficient power output.

Original factory precision fit, perfectly matching the hydraulic system layout

The XCMG XE2000 manifold (318307833) was specifically designed by the XCMG R&D team for the flow parameters and pipeline layout of the XE2000 hydraulic system, and has undergone fluid dynamics simulation and actual machine pressure testing verification. Its interface size accuracy is controlled within ±0.01mm, oil passage diameter tolerance is less than 0.02mm, and installation positioning error is ≤0.05mm, perfectly matching the interface parameters of core hydraulic components such as the main pump, main valve, and cylinder. Whether in high-pressure hydraulic oil diversion control or in multi-action complex operation flow distribution scenarios, it can achieve precise docking and installation, completely eliminating oil passage blockage or pressure loss problems caused by dimensional deviations, creating a “highly efficient and smooth” control center for the hydraulic system.

High-strength Material and Manufacturing Process, Ensuring Durability Under Extreme Conditions

Made from high-strength alloy forged steel (40Cr), this manifold boasts a tensile strength exceeding 800MPa and a hardness of HRC28-32 after tempering heat treatment, exhibiting excellent compressive strength and fatigue resistance. The internal oil passages are machined using precision deep-hole drilling and honing processes, achieving a surface roughness Ra≤0.8μm to minimize hydraulic oil flow resistance. The surface undergoes phosphating and multi-layer chrome plating protection, resulting in uniform plating thickness and strong adhesion. It has passed over 500 hours of salt spray testing, demonstrating over 40% improved corrosion resistance and more than 3 times longer service life compared to ordinary manifolds in high-humidity, dusty, and oil-contaminated mining environments.

Optimized Flow Channel Design, Enhancing Hydraulic Control Efficiency

The manifold features a streamlined oil passage design. Finite element analysis was used to optimize the oil passage layout, reducing pressure loss by over 15%. Its integrated valve assembly mounting holes allow for a compact layout of multi-way valves, shortening pipeline connection distances and reducing hydraulic shock and vibration noise. When the XE2000 excavator is operating at full load, it can precisely control hydraulic oil flow and pressure, ensuring coordinated movements such as boom lifting, stick extension, and bucket digging, improving response speed by 10%. This provides stable hydraulic power support for efficient operation of the 12 cubic meter bucket, avoiding sluggish movements or power waste caused by uneven flow distribution.

For mining companies pursuing efficient operation, the XCMG XE2000 manifold (318307833) is not only a high-quality hydraulic component but also the “core hub” ensuring precise control of the hydraulic system. Choosing original equipment manufacturer (OEM) parts means choosing reliability that perfectly matches the performance of the XE2000 excavator’s hydraulic system, providing a solid hydraulic control guarantee for efficient mining operations.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

318307832 high-pressure filter assembly

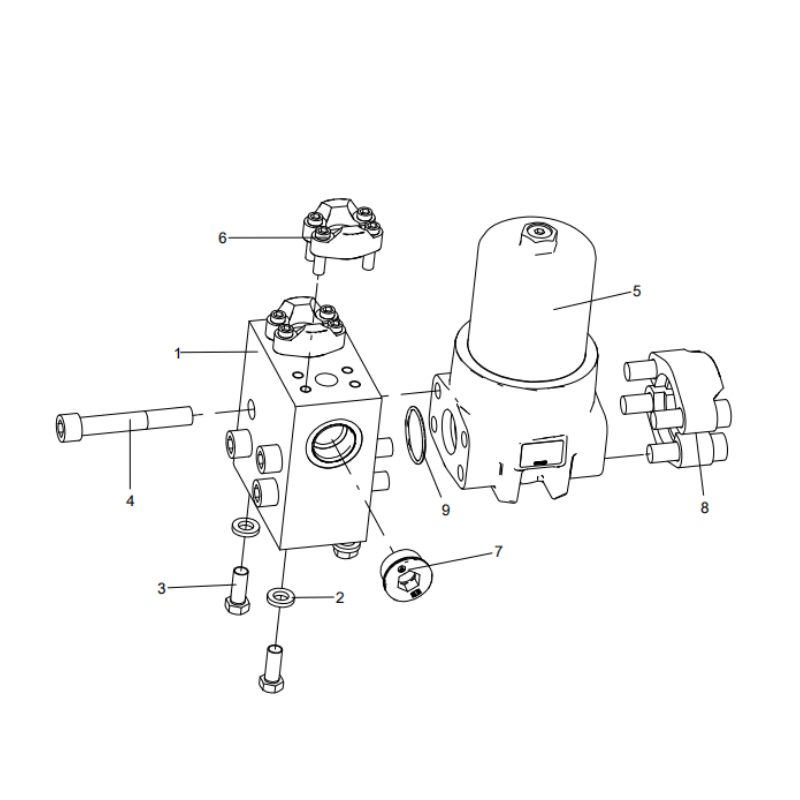

1 318307833 1 CONFLUENT BLOCK

2 329900304 4 THICKENED FLAT WASHER

3 805048287 4 BOLT M16×40 GB/T5782-2000

4 805141175 4 SCREW M20×130 GB/T70.1-2008

5 801139334 1 FILTER SERIES

6 803201542 2 FLANGE ASSEMBLY

7 803436991 2 PLUG

8 803418697 1 FLANGE ASSEMBLY

9 803303446 1 ORING 56.74×3.53-S AS568