Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307825 welding bracket XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Welded Support (318307825): Structural Support for Heavy-Duty Mining Equipment

In core mining regions worldwide, such as Indonesia, the Democratic Republic of Congo, and Brazil, the XCMG XE2000 mining excavator, with its 12-cubic-meter super-large bucket capacity and over 93% mobility, has become a core piece of equipment for efficient mining operations. Within this “mining giant’s” structural system, the welded support (part number 318307825) acts as a “load-bearing skeleton,” undertaking the tasks of fixing and supporting key components and transferring loads. It is a core structural component ensuring the stability of the entire machine and operational safety.

Precise Original Factory Fit, Perfectly Matching the Overall Machine’s Stress Layout

The XCMG XE2000 welded support (318307825) was specifically developed by the XCMG R&D team for the overall structural design and mechanical distribution of the XE2000, undergoing finite element simulation analysis and thousands of heavy-duty tests for verification. Its dimensional accuracy is controlled within ±0.4mm, and the tolerance of the mounting holes is less than 0.2mm, perfectly matching the connection interfaces with key components such as the boom, cylinder base, and frame. Whether under dynamic impact during excavation or static load support when the equipment is stationary, precise installation is achieved, completely eliminating structural misalignment or stress concentration problems caused by dimensional deviations, providing a seamless support foundation for the entire machine structure.

High-strength welding process, durable core under extreme conditions

Using low-alloy high-strength structural steel (Q355ND) as the base material, it is formed through a fully automated robotic welding process. Key welds adopt a double-bevel design, with uniform weld leg height and sufficient penetration. After 100% non-destructive testing, the welds are free of defects such as porosity and slag inclusions. The weld strength is consistent with the base material, with an overall tensile strength exceeding 560MPa and a yield strength ≥360MPa. The surface undergoes sandblasting (rust removal grade Sa2.5) followed by a double-layer anti-corrosion treatment with epoxy primer and topcoat, achieving a coating thickness of over 80μm. It has passed over 500 hours of salt spray testing. In the high humidity and dusty mining environment, its rust resistance is more than 50% higher than ordinary welded supports, and its service life is extended by more than 3.5 times.

Optimized mechanical structure enhances load-bearing and fatigue resistance

Through topology optimization and biomimetic mechanical design, the support achieves lightweight construction while ensuring strength, reducing its weight by 10% compared to traditional designs. Its multi-directional support grid structure evenly distributes concentrated loads during heavy-duty operations across the entire frame, capable of withstanding instantaneous impact forces up to 1300kN without plastic deformation. When the XE2000 excavator is operating at full load in hard rock, it effectively stabilizes the installation positions of critical components such as hydraulic lines and control valve groups, reducing vibration-induced component wear, indirectly improving equipment mobility, and ensuring uninterrupted continuous operation. For mining companies seeking efficient operations, the XCMG XE2000 welded support (318307825) is not only a high-quality structural component but also a “steel pillar” ensuring the safety of heavy-duty equipment operations. Choosing original equipment manufacturer (OEM) parts means choosing structural reliability that perfectly matches the performance of the XE2000 excavator, providing solid structural support for efficient mining operations.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

318307824 pipe clamp assembly

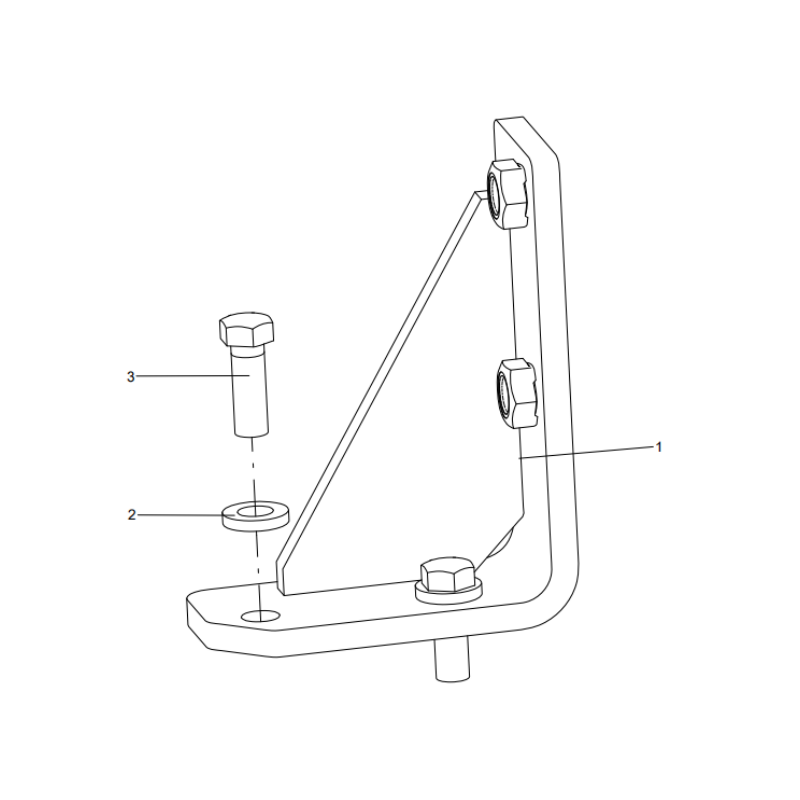

1 318307825 1 WELDING BRACKET

2 329900303 2 THICKENED FLAT WASHER

3 805046632 2 BOLT M12×35 GB/T5782-2000