Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

804414139 hose assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Hose Assembly (804414139): The Flexible Transmission Hub of the Hydraulic System

In the hydraulic power transmission network of the XE2000 large mining excavator, the hose assembly serves as a “flexible bridge” connecting fixed pipelines and moving actuators. Its performance directly affects the power output efficiency of the hydraulic system and the safety of equipment operation. XCMG’s original hose assembly (part number: 804414139) is specially designed and developed for the heavy-duty working conditions of this model. With its superior high-pressure resistance, precise dynamic adaptability, and excellent environmental adaptability, it becomes the core guarantee for efficient hydraulic oil transmission. Multi-layer reinforced pressure-resistant structure ensures safe and reliable high-pressure transmission.

The XE2000 excavator’s hydraulic system operates at pressures up to 35MPa, with instantaneous impact pressures reaching 45MPa, placing stringent requirements on the pressure resistance of the hoses. This hose assembly features a six-layer composite reinforced structure: the inner tube uses high-performance hydrogenated nitrile butadiene rubber (HNBR), treated with a special cross-linking process, improving oil penetration resistance by 45% and providing long-term resistance to high-pressure hydraulic oil corrosion; the middle layer is reinforced with double-layer high-strength galvanized steel wire braiding, with the braiding angle precisely controlled at 54°44′ and a braiding density exceeding 93%, achieving a burst pressure exceeding 115MPa, far exceeding the actual working pressure requirements of the system; the outer layer is covered with a wear-resistant neoprene rubber protective layer, reinforced with tear-resistant carbon fiber, achieving an impact strength of 32kN/m, effectively resisting mechanical damage such as rock impacts and friction scratches in mining operations. Under high-frequency pressure impact conditions, the hose radial expansion is ≤1.8%, ensuring leak-free hydraulic oil transmission and completely eliminating the risk of equipment downtime due to hose rupture.

Dynamic simulation optimization design, flexible layout for precise adaptation

The large-range movement of components such as the boom, stick, and slewing mechanism in the hydraulic system requires the hose to possess excellent flexibility and dimensional stability. The 804414139 hose assembly employs a 3D dynamic simulation optimization design. Finite element analysis simulates the entire machine’s motion trajectory under all working conditions, precisely customizing hose length and bending parameters: length tolerance is strictly controlled within ±1.5mm, and bending radius error ≤4mm, perfectly matching the dynamic layout requirements of the XE2000 excavator’s hydraulic piping. For the maximum displacement of moving parts, the minimum bending radius of the hose is optimized to 2.8 times the nominal diameter, maintaining a natural bending state even under extreme working conditions, avoiding structural fatigue caused by excessive stretching or torsion. The hose end connectors utilize CNC precision crimping technology, with a crimping depth error ≤0.08mm, ensuring a permanent and reliable connection between the connector and the hose, preventing loosening or detachment under high-frequency vibration environments, and guaranteeing continuous and stable hydraulic power transmission.

Deeply compatible with original factory parameters, enhancing system synergy efficiency

As a core flexible transmission component of the XE2000 excavator’s hydraulic system, the flow characteristics and interface parameters of this hose assembly have undergone full-process calibration by the original factory. To address the viscosity variations and flow requirements of hydraulic oil, the hose’s inner diameter is precisely controlled within ±0.15mm, and the inner bore undergoes a mirror-polishing process (surface roughness ≤Ra0.3μm). This reduces hydraulic oil flow resistance by more than 18% compared to ordinary hoses, minimizing pressure loss. The hose interface dimensions are seamlessly compatible with steel pipe assemblies (fitter number 318307798) and transition joints (fitter number 803150690), forming a low-resistance hydraulic transmission network and avoiding turbulent losses caused by size mismatches. Through integrated testing of the entire hydraulic system, this hose assembly accurately adapts to flow variations under different operating conditions, improving the response speed of hydraulic actuators by 10% and significantly enhancing equipment operating efficiency.

All-condition weather resistance protection, significantly extended service life

The extreme temperatures, dust, and oil content of mining environments pose a severe challenge to the hose’s weather resistance. The 804414139 hose assembly undergoes comprehensive environmental adaptability enhancement: its temperature resistance ranges from -55℃ to 135℃, maintaining excellent flexibility even in extremely cold environments (low-temperature brittleness temperature ≤ -65℃), and exhibiting no softening or deformation under high-temperature conditions. Its oil aging resistance is demonstrated by a 1800-hour immersion test in 120℃ hydraulic oil, with a volume change rate ≤ 2.5% and a hardness change ≤ 4 Shore A. The outer rubber layer incorporates UV stabilizers and anti-aging agents, showing no cracking or hardening after a 2500-hour UV aging test. In dusty mining environments, the hose’s outer layer features a nano-anti-stick coating, reducing dust adhesion by 65%. Combined with highly wear-resistant rubber, its service life is extended by over 90% compared to ordinary hoses, significantly reducing replacement frequency.

Strict quality control throughout the entire process ensures reliable performance

XCMG implements full life-cycle quality control for the 804414139 hose assembly, requiring 28 professional tests from raw material selection to finished product delivery. Each hose undergoes 100% high-pressure testing (55MPa for 10 minutes), helium mass spectrometry leak detection (leakage rate ≤1×10⁻¹⁰ Pa・m³/s), and burst testing to ensure no quality defects. The assembly also passes 1.8 million pulse fatigue tests (pressure range 0-35MPa), 1.2 million bending fatigue tests, and vibration tests (10-3000Hz) to verify structural stability under long-term dynamic operating conditions. The product fully complies with international standards such as ISO 1436 and SAE J517, providing multiple safety guarantees for high-pressure operation of the hydraulic system.

XCMG XE2000 excavator hose assembly (part number 804414139) – with its multi-layered reinforced structure to withstand extreme high pressure, dynamic design to adapt to complex working conditions, and comprehensive protection to extend service life, it is an indispensable flexible transmission hub for the hydraulic system of large mining excavators.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

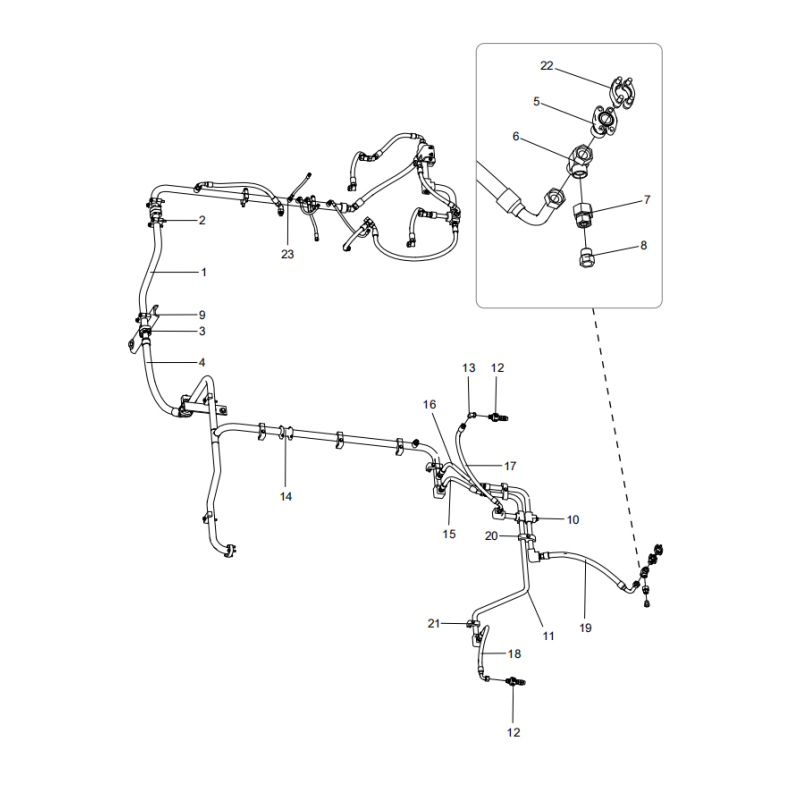

318307823 drain oil pipeline

1 318307798 1 STEEL PIPE ASSEMBLY

2 318006991 1 PIPE CLAMP ASSEMBLY

3 803164240 1 FLANGE ASSEMBLY

4 804414138 1 HOSE ASS’Y

5 803164697 1 BLIND FLANGE

6 803103777 1 CONNECTOR

7 803131927 1 CONNECTOR

8 803150690 1 CONNECTOR

9 318307802 1 PIPE CLAMP ASSEMBLY

10 318307822 1 STEEL PIPE ASSEMBLY

11 318307821 1 STEEL PIPE ASSEMBLY

12 318307819 2 CONNECTOR ASSEMBLY

13 803100741 1 CONNECTOR

14 318307815 1 STEEL PIPE ASSEMBLY

15 803382159 1 HOSE ASS’Y

16 803194411 1 HOSE ASS’Y

17 804414141 1 HOSE ASS’Y

18 803281494 1 HOSE ASS’Y

19 804414139 1 HOSE ASS’Y

20 318307812 2 CLAMP ASSEMBLY

21 318307811 1 PIPE CLAMP ASSEMBLY

22 803164234 1 FLANGE ASSEMBLY

23 318307808 1 MAIN PUMP OIL DRAIN PIPELINE

##