Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803150690 connector XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Connector (803150690): A Reliable Connection Node for Hydraulic Pipelines

In the hydraulic transmission system of the XE2000 large mining excavator, the connector is a key component for achieving precise connection between different pipelines and ensuring leak-free hydraulic oil transmission. Its sealing performance and structural stability directly affect the efficiency and safety of the entire machine’s hydraulic system. The XCMG original connector (part number: 803150690) is specifically designed for the high-pressure hydraulic pipelines of this model. With its precise sealing structure, strong pressure-bearing capacity, and original factory precision fit, it becomes a reliable core for hydraulic pipeline connections. Precision Sealing Structure, Zero Leakage in High-Pressure Transmission

The XE2000 excavator’s hydraulic system operates at pressures up to 35MPa, with instantaneous impact pressures reaching 42MPa, placing extreme demands on the sealing performance of the connectors. This connector features a double-seal design, with a high-precision conical metal seal and a high-pressure resistant O-ring (fluororubber) at the interface. The combination of a hard metal seal and a soft rubber seal creates an absolutely reliable sealing interface. The connector threads are machined using a high-precision rolling process, achieving a thread accuracy of 6g/6h. Combined with a special sealant coating, it maintains a reliable seal even under high-pressure hydraulic impact. High-pressure testing has verified that it can withstand continuous pressure at 45MPa water pressure for 1 hour without leakage, ensuring zero loss in hydraulic oil transmission and effectively preventing oil waste and environmental pollution caused by leakage.

High-strength material construction, excellent pressure resistance

Connectors in hydraulic systems must withstand high-pressure impacts and vibration loads for extended periods, requiring stringent material strength. The 803150690 connector is made of high-strength alloy structural steel (40Cr), integrally forged, with a tensile strength ≥980MPa and a yield strength ≥785MPa. After overall tempering heat treatment, its hardness reaches HRC28-32, exhibiting excellent fatigue resistance and impact toughness. Key load-bearing components have undergone structural optimization through finite element analysis, reducing stress concentration by 30%. This ensures no cracking or deformation occurs under high-frequency vibration and instantaneous high-pressure conditions, with an overall pressure resistance exceeding 55MPa, far surpassing the system’s actual working pressure requirements and providing a robust guarantee for hydraulic pipeline connections.

Original factory precision fitting ensures seamless pipeline connections

As a core hydraulic connection component of the XE2000 excavator, the connector’s dimensions and connection type have been fully calibrated by the original factory. Considering the layout characteristics of the machine’s hydraulic pipelines, the connector’s nominal diameter, connection angle, thread specifications, and other parameters are strictly matched to the interface requirements of components such as the steel pipe assembly (fitter number 318307798) and hose assembly (fitter number 804414138), ensuring seamless connection of pipelines of different diameters and materials. The installation and positioning accuracy of the connector is controlled within 0.1mm. Specialized tooling ensures the coaxiality of the connected pipelines, preventing additional stress caused by uneven force distribution and effectively reducing early wear on the pipelines and connectors. This ensures a reasonable pipeline layout and minimal flow resistance in the hydraulic system.

Precision machining process ensures stable and reliable performance

The machining accuracy of the connector directly affects the connection reliability and flow characteristics. This connector is precision-manufactured using a multi-axis linkage machining center. The surface roughness of the sealing surface is ≤Ra0.8μm, and the flatness error is ≤0.01mm/100mm, ensuring a tight seal. The inner bore is honed, with a surface roughness ≤Ra0.4μm, effectively reducing hydraulic oil flow resistance and pressure loss. All connectors undergo 100% hydrostatic testing, magnetic particle inspection, and dimensional inspection to ensure the absence of defects such as sand holes and cracks. The performance consistency of each batch of products reaches over 99.5%, providing reliable support for the stable operation of the hydraulic system. Full-cycle weather resistance, adaptable to extreme environments. Dust, oil, humidity, and temperature fluctuations in mining environments test the weather resistance of joints. The 803150690 joint surface undergoes multi-layer protective treatment: a bottom phosphate film enhances adhesion, a middle layer of electroplated hard chrome (≥15μm thickness) improves wear and corrosion resistance, and an outer layer is coated with oil-resistant and rust-proof paint, achieving an overall salt spray resistance of over 720 hours. Within a temperature range of -30℃ to 120℃, material properties and sealing performance remain stable without change, preventing seal failure due to alternating hot and cold temperatures. Verified in actual mining conditions, after long-term operation in dusty and high-humidity environments, the joint shows no rust or blockage, ensuring hydraulic oil cleanliness and transmission efficiency. XCMG XE2000 excavator connector (part number 803150690) – Featuring precision sealing to eliminate leakage risks, high-strength materials to withstand high-pressure loads, and original equipment manufacturer (OEM) fitment for seamless pipeline operation, this is an indispensable and reliable connection node for the hydraulic system of large mining excavators.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

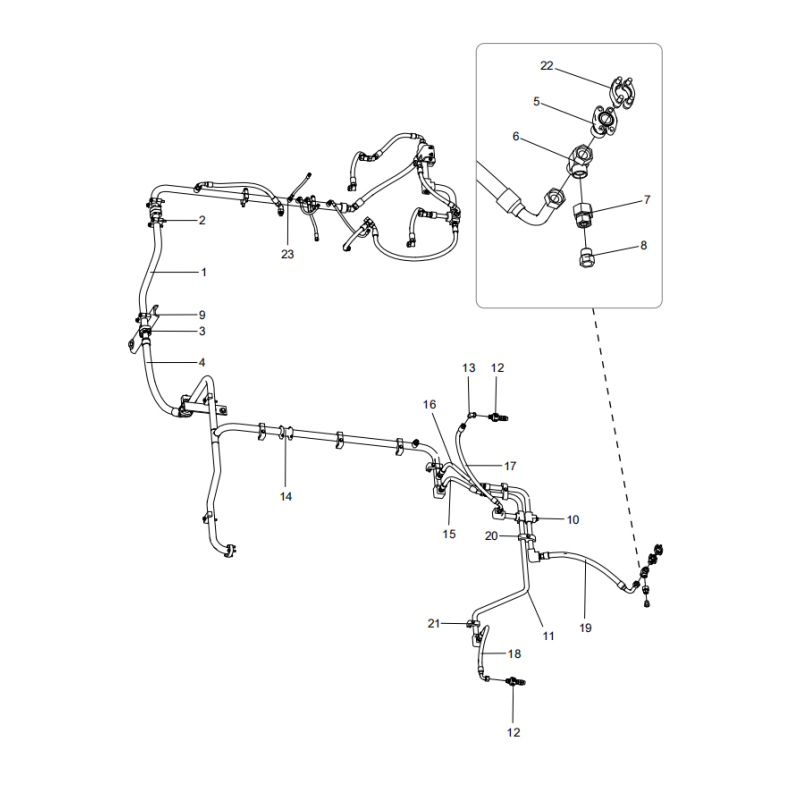

318307823 drain oil pipeline

1 318307798 1 STEEL PIPE ASSEMBLY

2 318006991 1 PIPE CLAMP ASSEMBLY

3 803164240 1 FLANGE ASSEMBLY

4 804414138 1 HOSE ASS’Y

5 803164697 1 BLIND FLANGE

6 803103777 1 CONNECTOR

7 803131927 1 CONNECTOR

8 803150690 1 CONNECTOR

9 318307802 1 PIPE CLAMP ASSEMBLY

10 318307822 1 STEEL PIPE ASSEMBLY

11 318307821 1 STEEL PIPE ASSEMBLY

12 318307819 2 CONNECTOR ASSEMBLY

13 803100741 1 CONNECTOR

14 318307815 1 STEEL PIPE ASSEMBLY

15 803382159 1 HOSE ASS’Y

16 803194411 1 HOSE ASS’Y

17 804414141 1 HOSE ASS’Y

18 803281494 1 HOSE ASS’Y

19 804414139 1 HOSE ASS’Y

20 318307812 2 CLAMP ASSEMBLY

21 318307811 1 PIPE CLAMP ASSEMBLY

22 803164234 1 FLANGE ASSEMBLY

23 318307808 1 MAIN PUMP OIL DRAIN PIPELINE

##