Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307468 main pump mounting XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Main Pump Bracket (318307468): The Solid Support Core for Main Pump Operation

In the power transmission system of the XE2000 large mining excavator, the main pump bracket is a key structural component that fixes the main pump and bears the power load. Its stability directly affects the operating accuracy of the main pump and the safety of the entire machine’s hydraulic system. The XCMG original main pump bracket (part number: 318307468) is specially customized and developed for this model. With its strong structural strength, precise installation positioning, and excellent durability, it becomes a solid guarantee for the efficient and stable operation of the main pump.

High-strength structural design, excellent load-bearing capacity

The XE2000 excavator’s main pump needs to withstand huge power impacts and vibration loads during operation, placing extremely high demands on the structural strength of the bracket. This main pump bracket adopts an integral casting process, using high-strength alloy cast steel (tensile strength ≥800MPa), and after age hardening treatment, its hardness reaches HB230-260, with an overall load-bearing capacity of over 50kN. The optimized mechanical structure, achieved through finite element analysis, increases the strength of stress concentration areas by 30%, maintaining structural stability even under high-frequency vibration and instantaneous impact conditions of the main pump. This effectively prevents deformation and breakage, ensuring the main pump remains in a precise working position and guaranteeing efficient and lossless hydraulic power transmission.

Precision machining process ensures zero-error installation and positioning

Precise docking between the main pump and engine is crucial for ensuring power transmission efficiency, placing stringent requirements on the machining precision of the bracket. The 318307468 main pump bracket is precision-manufactured using a five-axis linkage machining center, with a flatness error of ≤0.05mm/m for the mounting reference surface and a positional error of ≤0.1mm for the positioning holes, achieving a perfect match with the connection interfaces of the main pump and engine. The bracket surface undergoes phosphate anti-rust treatment and paint protection, improving corrosion resistance and ensuring the flatness of the mounting surface, reducing additional vibration during main pump operation. Precise installation and positioning control the coaxiality error between the main pump and engine within 0.1mm, effectively reducing energy loss and component wear during power transmission and extending the service life of the main pump.

Original Factory Parameter Adaptation, Seamless System Integration

As a core structural component of the XE2000 excavator, the main pump bracket’s dimensions and mechanical properties have been fully calibrated by the original factory. Specifically optimized for the main pump’s weight distribution, vibration frequency, and power transmission characteristics, the bracket’s stiffness and damping characteristics effectively absorb and buffer the vibration energy generated by the main pump’s operation, reducing vibration transmission to the entire machine structure. The bracket’s mounting holes and load-bearing supports strictly adhere to original factory design specifications. The connection method with the main pump and engine block has undergone fatigue strength verification, ensuring that the connecting bolts remain secure and the bracket remains crack-free under long-term high-intensity operation. This guarantees the coordinated operation of all components of the power system and avoids abnormal wear of the main pump or hydraulic system failure due to poor bracket compatibility.

Full Lifecycle Weather Resistance, Adaptable to Extreme Working Conditions

Dust, humidity, and temperature differences in the mining environment pose a challenge to the bracket’s weather resistance. This main pump bracket features a multi-layered protective treatment: a bottom phosphate coating enhances adhesion, a middle epoxy resin primer provides rust prevention, and an outer wear-resistant topcoat resists impact. Overall, it boasts a salt spray resistance of over 500 hours. Within a temperature range of -30℃ to 60℃, the material’s physical properties remain stable without change, preventing stress cracking due to alternating hot and cold temperatures. Verified in actual mining conditions, under 16 hours of high-intensity operation per day in dusty and humid environments, the bracket can achieve over 8000 hours of trouble-free operation, significantly reducing maintenance and replacement frequency.

The XCMG XE2000 excavator main pump bracket (part number 318307468) – with its high-strength structure bearing the power load, precision machining ensuring accurate connection, and original equipment manufacturer (OEM) compatibility achieving system synergy, it is an indispensable and robust support core for the stable operation of the main pump in large mining excavators.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

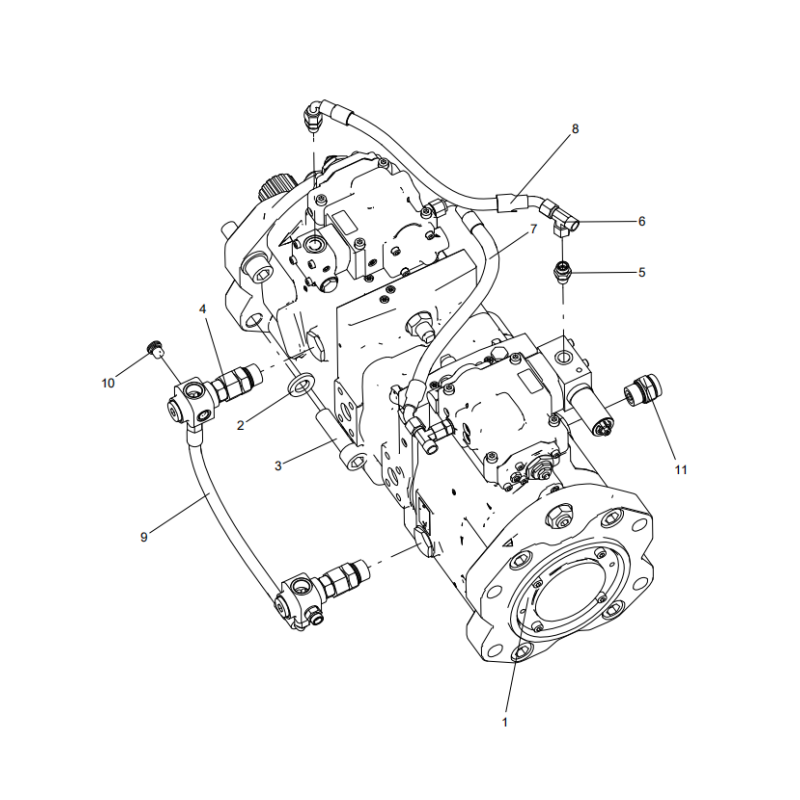

318307468 main pump mounting

1 804001727 1 MAIN PUMP

2 329900385 4 THICKENED FLAT WASHER

3 805140490 4 SCREW M20×70 GB/T70.1-2008

4 318307471 2 TRANSITION JOINT ASSEMBLY

5 803172014 5 CONNECTOR

6 803105353 2 CONNECTOR

7 804414170 1 HOSE ASS’Y

8 804414169 1 HOSE ASS’Y

9 803381671 1 HOSE ASS’Y

10 803172186 1 PLUG

11 803107270 2 CONNECTOR

##