Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803402034 connector XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Connector (803402034): The High-Efficiency Connection Hub of the Circuit System

In the complex circuit network of the XE2000 large mining excavator, connectors are key nodes ensuring stable transmission of electrical signals and power. XCMG’s original connector (part number: 803402034) is custom-developed for this model, leveraging its precise connection technology, robust environmental adaptability, and original equipment manufacturer (OEM) compatibility to become the core guarantee for the reliable operation of the circuit system under high-intensity mining operations.

Micro-precision contact technology for efficient and lossless signal transmission

The XE2000 excavator’s intelligent control system relies on real-time signal interaction between multiple modules, requiring extremely high connection precision. This connector adopts a micro-precision pinhole contact design, with pins made of high-purity oxygen-free copper. After multi-layer gold plating, the surface roughness is ≤0.02μm, and the contact resistance is stably controlled within 3mΩ, achieving low-loss transmission of electrical signals. The flexible contact structure, coupled with a 0.05mm tolerance, maintains continuous and stable contact even under high-frequency vibration conditions, effectively preventing signal interruption and delay. Whether it’s hydraulic system pressure feedback, engine condition monitoring, or operational command transmission, millisecond-level response is achieved, ensuring an overall machine control precision improvement of over 15%.

Military-grade protection system, confidently handling extreme environments

The harsh environments of mining operations, including dust, oil, and extreme temperatures, pose stringent challenges to the connector’s protective performance. The 803402034 connector shell uses a reinforced PBT engineering plastic and metal insert composite structure, achieving an impact strength of 20kJ/m² and passing UL94 V0 flame retardant certification. The interface features a triple-seal design, with built-in fluororubber sealing rings, dust plugs, and metal locking rings, achieving an IP6K9K protection rating, completely resisting high-pressure water jets, oil immersion, and dust intrusion. Verified through extreme environment testing, this connector exhibits stable performance within a temperature range of -45℃ to 130℃, shows no rust after 500 hours of salt spray testing, and boasts an 80% longer service life than ordinary connectors, effectively reducing the risk of failure due to environmental corrosion.

Original factory precise fit, seamless system compatibility

As a core component of the XE2000 excavator, this connector’s electrical parameters and mechanical dimensions have been fully calibrated by the original manufacturer. Designed for the machine’s 12V/24V mixed circuit architecture, it has a rated current of 25A and an insulation withstand voltage ≥1000V, perfectly matching the electrical requirements of key equipment such as the main controller, sensor clusters, and actuators. The modular positioning design of the mounting interface ensures a fit error of ≤0.02mm with the equipment’s circuit interface, allowing for rapid assembly without additional adjustments. Compatibility testing with the entire machine’s circuit system completely avoids signal interference and component burnout caused by parameter mismatches, ensuring efficient and coordinated operation of the circuit system.

Full-process quality control, multiple safety guarantees

XCMG implements stringent full-lifecycle quality control for its 803402034 connector, requiring 20 professional tests from raw material selection to finished product delivery. Each batch of products undergoes vibration testing (10-3000Hz), shock testing (1500G acceleration), and damp heat cycling testing (-40℃ to 85℃, 95% humidity) to ensure structural stability and electrical performance under extreme conditions. The product complies with IEC 60529 protection standards and mining equipment safety specifications, and features built-in overcurrent protection design, which can quickly cut off the circuit in abnormal situations such as short circuits and overloads, providing multiple guarantees for the safety of operators and equipment.

The XCMG XE2000 excavator connector (part number 803402034) – ensuring smooth signal transmission with micro-precision contacts, withstanding environmental challenges with military-grade protection, and ensuring system compatibility with original equipment manufacturer (OEM) adapters – is an indispensable and efficient connection hub for the electrical systems of large mining excavators.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

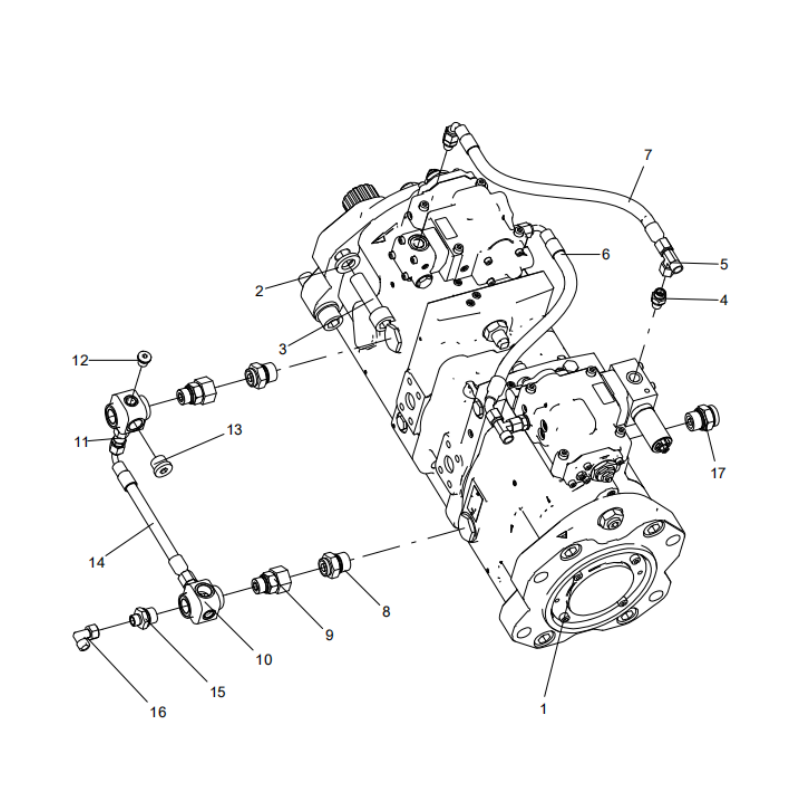

318307467 main pump mounting

1 804001727 1 MAIN PUMP

2 329900385 4 THICKENED FLAT WASHER

3 805140490 4 SCREW M20×70 GB/T70.1-2008

4 803172014 6 CONNECTOR

5 803105353 2 CONNECTOR

6 804414170 1 HOSE ASS’Y

7 803170872 1 HOSE ASS’Y

8 803413396 2 CONNECTOR

9 803012821 2 CONNECTOR

10 318811022 2 TRANSIT JOINT

11 803402034 1 CONNECTOR

12 803172186 2 PLUG

13 803189850 1 PLUG

14 803101926 1 HOSE ASS’Y

15 803164250 1 CONNECTOR

16 803103351 1 CONNECTOR

17 803107270 2 CONNECTOR

#XCMG XE2000 hydraulic transition joint, excavator pipeline joint 318811022, high-pressure hydraulic accessories, ISO standard joints, excavator pipeline modification#