Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803170872 hose assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Hoses (803170872): A High-Efficiency Transmission Channel for the Hydraulic System

In the hydraulic system of the XE2000 large mining excavator, the hose assembly is the “blood vessel” connecting various core components and ensuring efficient hydraulic oil transmission. XCMG’s original hose assembly (part number: 803170872) is specially customized for this model, offering superior pressure resistance, wear resistance, and precise fit, making it a key guarantee for the stable operation of the hydraulic system.

High-Pressure Tolerance Design Ensures Efficient Power Transmission

The XE2000 excavator’s hydraulic system operates at pressures up to 35MPa, placing stringent requirements on the pressure resistance of the hoses. This hose assembly features a multi-layer reinforced structure design. The inner tube is made of high-pressure resistant synthetic rubber, the middle layer is reinforced with high-strength braided steel wire, and the outer layer is covered with a wear-resistant protective rubber layer. With a rated working pressure of 40MPa, far exceeding the actual system requirements, it can easily cope with the instantaneous high pressure brought by hydraulic shocks. Under extreme working conditions such as hard rock excavation and heavy-duty hoisting, it maintains leak-free and expansion-free pipelines, ensuring efficient transmission of hydraulic oil from the main pump to the actuators and guaranteeing precise and powerful operation of the working device.

Weather-resistant and wear-resistant material, adaptable to harsh mining environments

In mining operations, hoses must withstand multiple challenges, including oil erosion, mechanical friction, and extreme temperature variations. The outer layer of the 803170872 hose assembly uses a special formula rubber that is oil-resistant and ozone-resistant, improving anti-aging performance by more than 50% and providing long-term resistance to corrosion from mineral oil and hydraulic oil. The middle steel wire braided layer uses high-tensile-strength galvanized steel wire, processed with a precision braiding technique, achieving a tensile strength of 1800 N/mm², effectively resisting fatigue damage caused by pipeline vibration. Verified through high and low temperature cycle testing from -40℃ to 120℃, it maintains good flexibility even in extreme temperature environments in mining areas, avoiding low-temperature embrittlement or high-temperature softening, extending its service life by 60% compared to ordinary hoses. Precise Size Fit, Optimized and Efficient Piping Layout

As a core component of XCMG’s original equipment manufacturer (OEM), the length, diameter, and connector angle of this hose assembly are precisely designed according to the layout of the XE2000 hydraulic system. Customized bending radius designs are used to address the installation space requirements of different locations, avoiding pressure loss or fatigue fracture caused by excessive pipe bending. The connectors are made of high-strength forged steel, precision machined and chrome-plated. The crimping process with the hose is completed using automated equipment, with crimping accuracy controlled within ±0.1mm to ensure reliable sealing performance. After installation, it perfectly connects with the interfaces of the main pump, main valve, cylinder, and other components. The compact and reasonable piping layout reduces hydraulic oil flow resistance and improves system response speed.

Full-Process Quality Control, Worry-Free Safety

XCMG implements full life-cycle quality control for the 803170872 hose assembly, requiring 12 rigorous testing procedures from raw material procurement to finished product delivery. Each hose undergoes a water pressure test at 1.5 times its rated pressure, a pulse fatigue test, and a leak detection test to ensure there are no sand holes, air bubbles, or loose joints, thus eliminating potential quality issues. The product complies with ISO 1436 standards and mining equipment safety regulations, preventing hose bursts or detachments during high-pressure operations, providing robust protection for operator and equipment safety.

XCMG XE2000 Excavator Hoses (Part No. 803170872) – Ensuring power transmission with high-pressure resistance, resisting environmental corrosion with weather-resistant materials, and optimizing system efficiency with precise fit, it is an indispensable and reliable transmission channel for the hydraulic systems of large mining excavators.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

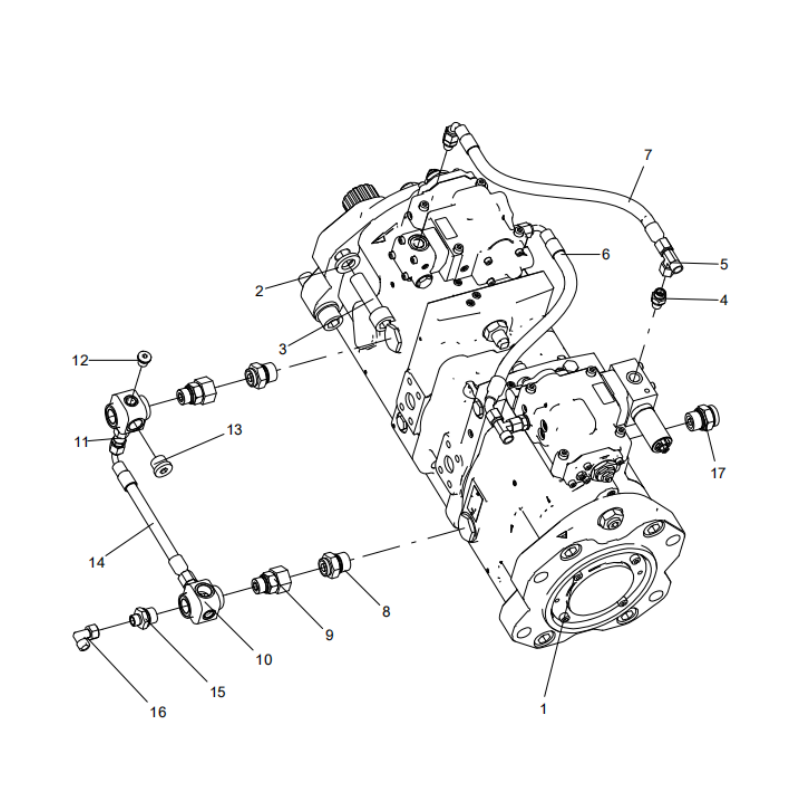

318307467 main pump mounting

1 804001727 1 MAIN PUMP

2 329900385 4 THICKENED FLAT WASHER

3 805140490 4 SCREW M20×70 GB/T70.1-2008

4 803172014 6 CONNECTOR

5 803105353 2 CONNECTOR

6 804414170 1 HOSE ASS’Y

7 803170872 1 HOSE ASS’Y

8 803413396 2 CONNECTOR

9 803012821 2 CONNECTOR

10 318811022 2 TRANSIT JOINT

11 803402034 1 CONNECTOR

12 803172186 2 PLUG

13 803189850 1 PLUG

14 803101926 1 HOSE ASS’Y

15 803164250 1 CONNECTOR

16 803103351 1 CONNECTOR

17 803107270 2 CONNECTOR

##