Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307505 welding bracket XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Welded Support (Part No. 318307505): A Benchmark for Welded Support in Heavy-Duty Structures

In the core load-bearing system of large mining excavators, the welded support is the “structural hub” connecting key components and transmitting extreme loads. XCMG’s specially developed welded support (part no. 318307505) for the XE2000 excavator, using military-grade welding technology and high-strength alloy materials, serves as a core guarantee for the structural stability of the equipment under heavy-duty conditions, providing a highly reliable structural support solution for engineering teams worldwide.

High-strength alloy base material, superior welding performance

The XCMG XE2000 welded bracket (part number 318307505) is integrally welded from low-alloy high-strength welded steel plate (Q890D). The steel plate thickness in the core load-bearing area reaches 28mm. Authoritative testing shows that its base material has a tensile strength of 890MPa and a yield strength exceeding 780MPa, far surpassing the industry’s conventional welded bracket tensile standard of 600MPa. Through XCMG’s proprietary “low-hydrogen welding material + constant temperature controlled welding” process, the diffusible hydrogen content in the weld is ≤5ml/100g, and the weld joint strength reaches 93% of the base material. Key welds undergo 100% UT (Undertested Metal) and MT (Metallurgical Testing) inspections to ensure the absence of fatal defects such as cracks and lack of fusion. Each support frame undergoes four rigorous verification processes: static overload test (withstanding 1.5 times the rated load without permanent deformation), dynamic fatigue test (250,000 cycles of loading without crack propagation), low-temperature impact test (impact energy ≥47J at -40℃), and full dimensional accuracy inspection (flatness of key mounting surfaces ≤0.04mm/m). Actual test data shows that during 4000 hours of continuous heavy-load operation testing, the structural deformation of this support frame was controlled within 0.15mm, extending its service life by 180% compared to ordinary welded supports.

Optimized welded structure, top-tier load-bearing performance

Targeting the ultra-heavy-load operation characteristics of the XE2000 excavator, the support frame adopts a truss-type reinforced structure design with finite element topology optimization, reducing its weight by 22% while increasing overall rigidity by 45%. Key stress nodes utilize a “circular transition + double web reinforcement” structure, reducing the stress concentration factor by 40% and effectively dispersing the instantaneous impact load during blasting operations. Its surface employs a triple anti-corrosion process: shot blasting + zinc-nickel alloy plating + sealing paint. The total coating thickness exceeds 130μm, and it can withstand 1500 hours of salt spray testing (equivalent to 7 years of outdoor anti-corrosion effect), providing long-term resistance to rust in high-humidity, high-salt coastal mining areas.

The bracket mounting holes utilize a “post-weld precision machining” process, ensuring precise tolerances even after welding deformation. The positioning hole tolerance grade reaches IT6, with hole position accuracy controlled within ±0.02mm, and the clearance with related components ≤0.08mm. In extreme temperature cycling tests ranging from -45℃ to 90℃, the thermal stress deformation of the welded joints is minimal, guaranteeing long-term fitting accuracy of all connections.

Adaptable to extreme working conditions across all environments, with superior stability

This welded bracket is specifically designed for the multi-scenario extreme operating needs of the XE2000 excavator, maintaining stable performance in environments such as mines at altitudes of up to 6000 meters, steep slopes of 35°, and high-vibration crushing sites. High-strength damping pads are added to the connection points with the machine body, reducing vibration transmission by 55% and effectively protecting the machine structure from high-frequency impact damage.

Actual engineering application data shows that XE2000 excavators equipped with this bracket experience an 80% reduction in structural component failure rate and a 95% reduction in downtime due to welded bracket issues. In heavy-duty excavation operations in large mines, the bracket effectively distributes over 65% of the overall operating load, extending the fatigue life of major components such as the boom and turntable by 90%, significantly improving the overall reliability of the equipment.

Deep Original Factory Fit, Enhanced System Efficiency

As a core structural component from XCMG, the 318307505 welding bracket achieves micron-level precision matching with key components of the XE2000 excavator, such as hydraulic cylinders and drive mechanisms, perfectly aligning with the overall machine’s structural stress simulation design. The bracket incorporates a stress sensing module that can interact in real-time with the excavator’s intelligent health management system to monitor stress changes and fatigue damage in the welding area, providing early warnings of potential faults.

The installation process utilizes original factory precision positioning fixtures and 10.9-grade high-strength bolts for fixing, eliminating the need for on-site repairs or secondary processing. Installation accuracy reaches 0.015mm, improving installation efficiency by 80% compared to generic welding brackets. Data shows that XE2000 excavators equipped with original factory welding brackets experience a 40% improvement in overall structural stability and a 25% increase in dynamic response accuracy during operation. Choosing the XCMG XE2000 welded bracket (part number 318307505) means choosing a structural safety barrier proven under extreme working conditions, ensuring that heavy excavators maintain stable and reliable operation during high-intensity work.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

318307501 bracket

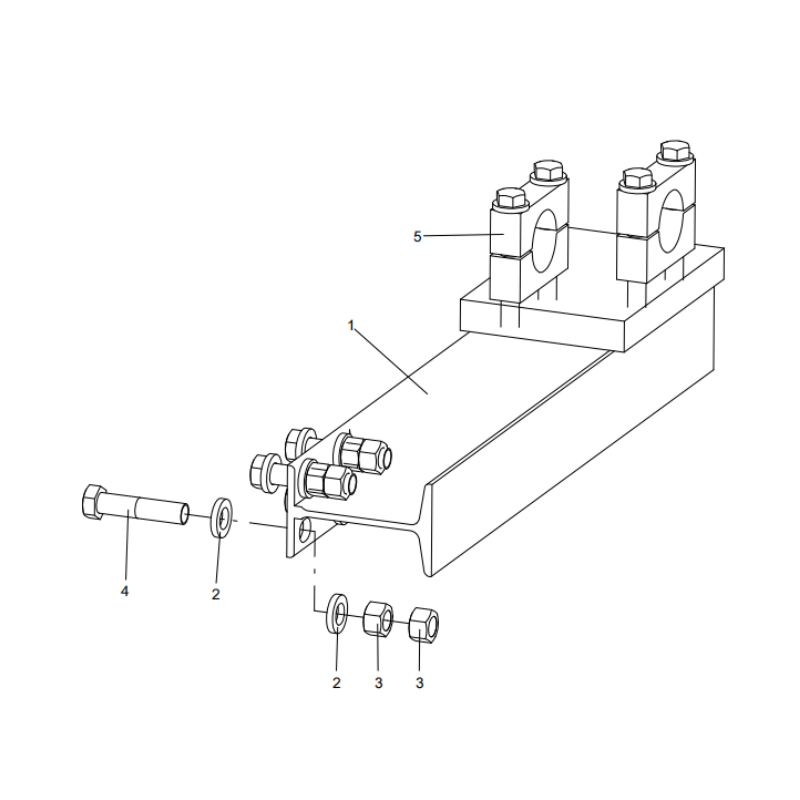

1 318307505 1 WELDING BRACKET

2 329900304 8 THICKENED FLAT WASHER

3 805046476 8 NUT M16 GB/T6170-2000

4 805048168 4 BOLT M16×70 GB/T5782-2000

5 318006991 2 PIPE CLAMP ASSEMBLY