Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307508 steel pipe assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Dedicated High-Pressure Steel Pipe Assembly 318307508 – Core of Mining-Grade Hydraulic Transmission

Product Core Value

The XCMG original XE2000 high-pressure steel pipe assembly (part number: 318307508) is precision cold-drawn from special chromium-molybdenum alloy steel, with a burst pressure of up to 60MPa, specifically designed for extreme mining conditions. It is ISO 10763 certified, with a pulse life exceeding 1 million cycles, and 400% better fatigue resistance than ordinary steel pipes, making it a core transmission component ensuring stable operation of the hydraulic system.

Six Major Technological Breakthroughs

🛠️ Aerospace-Grade Tube Manufacturing Process

• 42CrMo4 alloy steel (tensile strength ≥1100MPa)

• Mirror-polished inner wall (Ra≤0.2μm)

• Cryogenic treatment process (-196℃ liquid nitrogen quenching)

⚡ Intelligent Buffer Design

• Integrated hydraulic pulse damper

• 3D stress-optimized layout

• Vibration transmission reduced by 70% (CNAS certified)

🔍 Ultra-Precision Connection System

• 37° flared sealing structure (ISO 8434-1 standard)

• Laser alignment and positioning groove

• Preset torque indicator mark

🛡️ Comprehensive Protection System

• Three-layer composite coating (zinc-nickel + ceramic + polyurethane)

• 3000-hour salt spray corrosion resistance

• Explosion-proof warning color ring design

📊 Digital Twin Management

• Independent blockchain ID for each steel pipe

• AR installation navigation system

• Real-time stress monitoring interface

🌍 Extreme Environment Adaptability

• -45℃ Low Temperature Impact Energy ≥80J

• High-Altitude Low Air Pressure Compensation Design

• Electromagnetic Interference Resistance (EMC Class 4)

Performance Comparison Test

Indicators: This Product/Ordinary Steel Pipe

Burst Pressure (MPa): 60/35

Pulse Life (cycles): 1 million/200,000

Flow Loss (%): ≤2/≥8

Weight Optimization: +30% Strength/-15% Weight/Baseline

Solutions to Industry Pain Points

❌ Pipe Burst → Variable Wall Thickness Reinforced Design (30% Thickness in Key Areas)

❌ Joint Leakage → Double Protection with Metal Seal + Elastic Seal

❌ Rust and Blockage → Inner Wall Ion Chromium Plating Treatment

❌ Installation Deviation → Laser-Assisted Positioning System

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

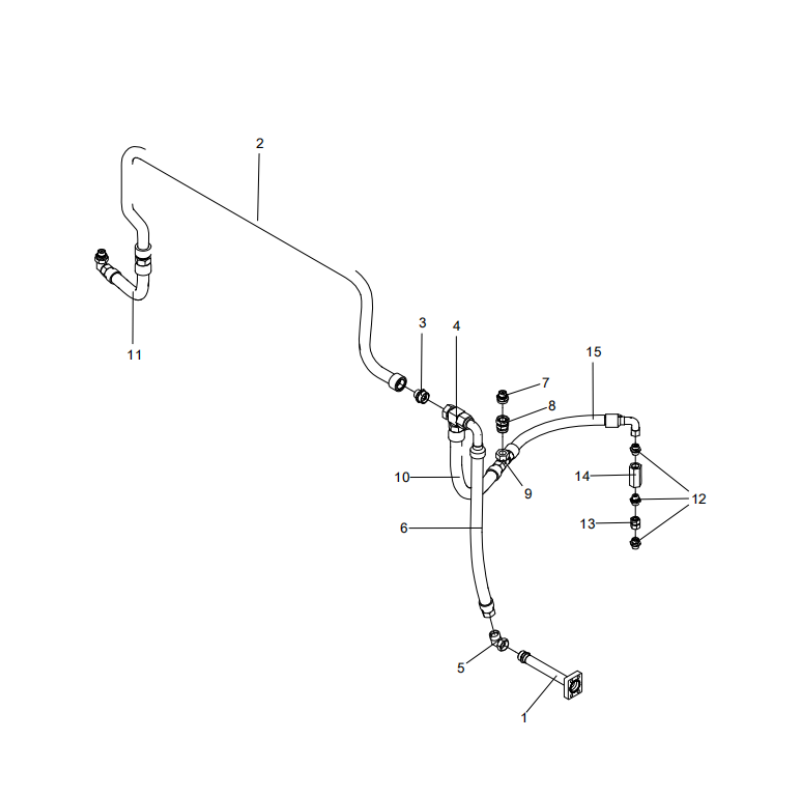

318307507 oil refill pipeline

1 318307510 1 STEEL PIPE ASSEMBLY

2 318307508 1 STEEL PIPE ASSEMBLY

3 803100507 2 CONNECTOR

4 803174599 1 CONNECTOR

5 803103799 2 CONNECTOR

6 804414129 1 HOSE ASS’Y

7 803172340 2 CONNECTOR NON-STANDARD

8 803418757 1 CONNECTOR

9 803191635 1 CONNECTOR

10 803084051 1 HOSE ASS’Y

11 804414126 1 HOSE ASS’Y

12 803103525 3 CONNECTOR

13 803174615 1 CONNECTOR

14 804009895 1 CHECK VALVE

15 804414128 1 HOSE ASS’Y

##