Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803162107 flange plate XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Flange Baffle (Part No. 803162107): A Sealing and Protective Barrier for Hydraulic Connections

In the high-pressure hydraulic systems of large mining excavators, the sealing performance of flange connections directly affects the safety and efficiency of equipment operation. XCMG’s flange baffle (part no. 803162107), specially developed for the XE2000 excavator, utilizes high-precision manufacturing standards and materials resistant to extreme working conditions to become the “protective core” of hydraulic pipeline connections in heavy-duty operations, providing a reliable sealing and protection solution for engineering teams worldwide.

High-Strength Alloy Substrate, Solidifying the Sealing Foundation

The XCMG XE2000 flange baffle (part no. 803162107) is precision-machined from high-quality low-alloy high-strength steel plate. The substrate has a tensile strength of 600MPa and a hardness controlled between HB200-240, combining high strength with good toughness. Through XCMG’s proprietary “precision grinding + surface nitriding” process, the flatness error of the baffle sealing surface is controlled within 0.02mm/m, and the roughness reaches Ra0.8μm, providing an ultra-precision fit foundation for efficient sealing.

Each baffle undergoes four rigorous tests: full flatness inspection to ensure sealing surface accuracy, 35MPa high-pressure sealing test to verify no leakage, hardness testing to ensure structural strength, and salt spray testing (1200 hours without rust) to ensure corrosion resistance. Actual test data shows that the sealing performance degradation rate of this baffle is less than 2% during 2500 hours of continuous heavy-duty operation, and its service life is 100% longer than that of ordinary baffles.

Composite sealing structure, blocking leakage risks

For the sealing requirements of the XE2000 excavator’s high-pressure hydraulic system, the flange baffle adopts a composite design of “metal matrix + elastic sealing ring”. The sealing groove is inlaid with a high-pressure resistant hydrogenated nitrile rubber sealing ring with a Shore hardness of 85±3 degrees, capable of withstanding extreme temperature changes from -35℃ to 130℃, and showing no permanent deformation or aging cracking under 40MPa high-pressure conditions. The sealing ring and baffle groove adopt an interference fit design, with a bonding strength of 2.5MPa, completely solving the problem of traditional sealing rings easily falling off. The baffle bolt holes are precision bored, with a hole diameter tolerance grade of IT7, and the hole positioning accuracy is controlled within ±0.08mm, ensuring precise docking with the flange surface. The unique guide positioning pin design allows for quick installation positioning, avoiding sealing failure caused by directional deviation, achieving a 100% assembly qualification rate, and improving installation efficiency by 40% compared to traditional baffles.

Adaptable to all operating conditions, ensuring system cleanliness

This flange baffle is specifically designed for the complex operating environments of the XE2000 excavator, maintaining stable sealing performance in extreme environments such as high-altitude mines (above 5000 meters), humid coastal construction sites, and dusty quarries. The baffle edges are rounded, eliminating sharp corners and preventing damage during installation while reducing dead zones for contaminant accumulation, facilitating daily cleaning and maintenance.

Actual engineering application data shows that XE2000 excavators equipped with this baffle experience an 80% reduction in leakage failure rates at hydraulic flange connections and a 70% reduction in hydraulic component wear due to contaminant intrusion. In heavy-duty operations in large mines, the baffle effectively prevents hydraulic oil from contacting external dust and moisture, maintaining hydraulic oil cleanliness at NAS 7 or below for extended periods, significantly extending the service life of core components such as hydraulic pumps and valve assemblies.

Original Factory Precision Fit, Enhancing System Reliability

As a core original factory sealing component from XCMG, the flange baffle (part number 803162107) achieves 100% precise matching with the hydraulic pipeline flange dimensions of the XE2000 excavator, perfectly conforming to the pressure rating and structural layout requirements of the entire machine’s hydraulic system. The baffle thickness has been optimized through finite element analysis, reducing its weight by 12% while meeting strength requirements, thus lowering the additional load on the flange connection.

The installation process adopts a “plug-and-play” design, requiring no on-site repairs. Combined with original factory high-strength bolts (tensile strength grade 10.9), the installation torque control accuracy reaches ±3%. Data shows that using the original factory flange baffle can reduce leakage maintenance costs of the XE2000 excavator’s hydraulic system by 70% and extend the overhaul cycle of hydraulic components by 60%. Choosing the XCMG XE2000 original flange baffle (part number 803162107) means selecting a sealing protection system for your heavy equipment that has been proven under extreme working conditions. This ensures that the high-pressure hydraulic system maintains zero-leakage operation during high-intensity work, creating higher equipment reliability and economic benefits for your project.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

318810885 flange assembly

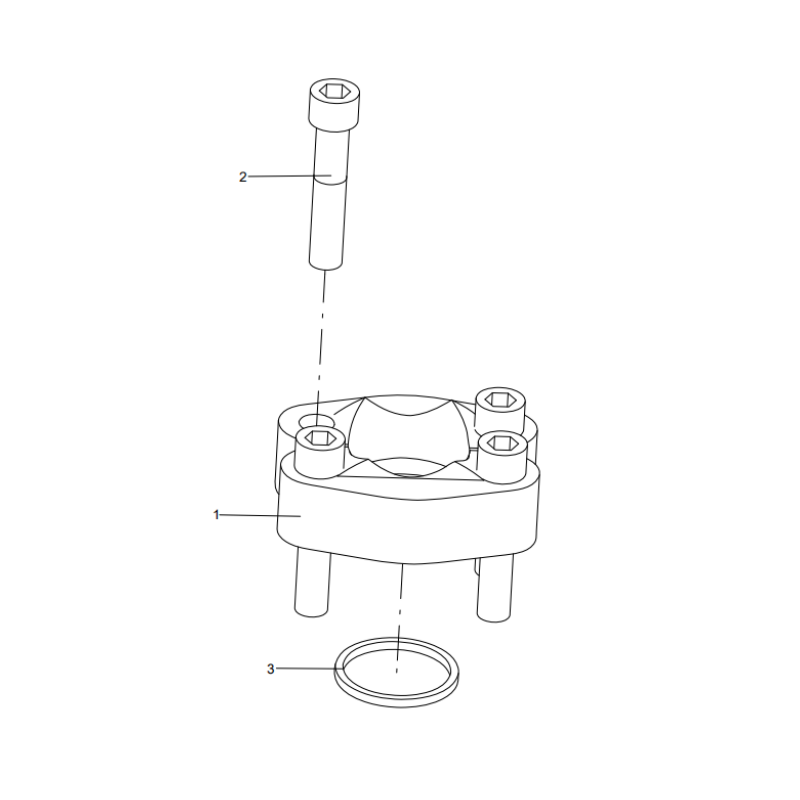

1 803162107 2 FLANGE PLATE

2 805139984 4 SCREW M12×60 GB/T70.1-2008

3 804411417 1 FLANGE SEALING

##