Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

804411417 flange sealing XCMG XE2000 excavator spare parts

Share:

Product Details:

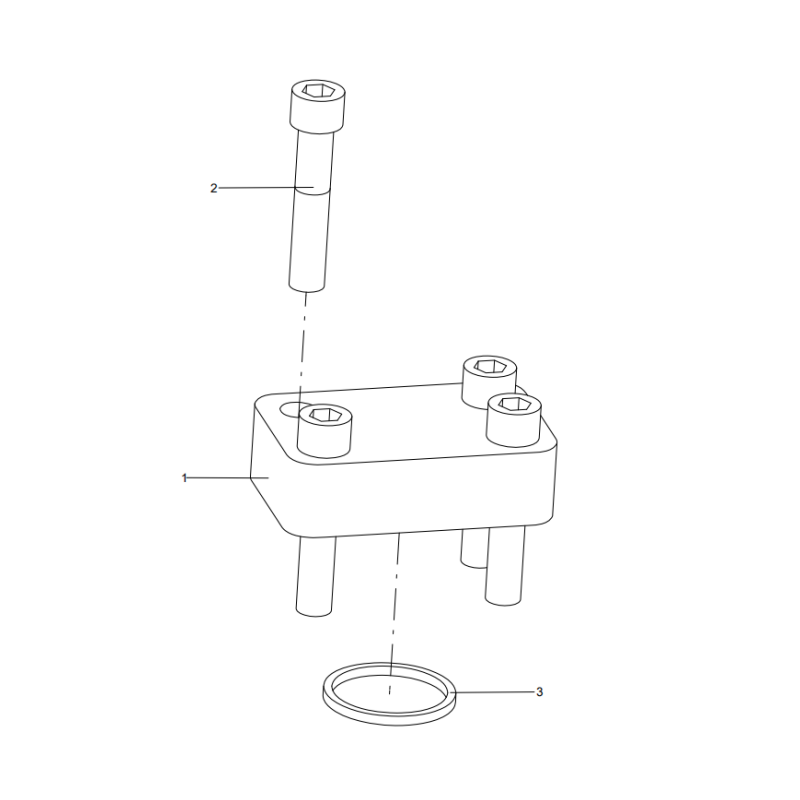

XCMG XE2000 Pipe Clamp Assembly (Part No. 804411417): Stable Sealing Guarantee for Hydraulic Pipelines

In the hydraulic piping system of large mining excavators, the pipe clamp assembly is a core component for maintaining the stability of the piping layout and eliminating vibration hazards. XCMG’s specially developed pipe clamp assembly (part no. 804411417) for the XE2000 excavator, with its high-strength materials and precision structural design, serves as the “fixed hub” for the safe operation of the piping system under heavy-duty conditions, providing a reliable piping fixation solution for engineering teams worldwide.

High-Strength Alloy Material for Durable Clamping Force

The XCMG XE2000 pipe clamp assembly (part no. 804411417) is forged from high-quality alloy steel, with a tensile strength of 700MPa for the core clamping component, 40% higher than conventional pipe clamps in the industry. Through a precision heat treatment process of “high-temperature quenching + low-temperature tempering,” the overall hardness of the pipe clamp is uniformly controlled between HRC40 and 45, ensuring both strong clamping rigidity and excellent impact resistance, preventing breakage under severe vibration.

Each component undergoes three rigorous tests: static clamping force reaches 8kN, withstanding twice the rated load without permanent deformation; after 300,000 vibration fatigue tests, the clamping force attenuation rate is less than 3%; and after 1200 hours of continuous salt spray testing, there is no rust, equivalent to 6 years of outdoor corrosion protection. Actual test data shows that this component maintains a stable clamping state during 3000 hours of continuous heavy-duty operation, extending its service life by 120% compared to ordinary pipe clamps.

Composite sealing design prevents vibration leakage

To address the sealing requirements of the XE2000 excavator’s high-pressure hydraulic system, the pipe clamp assembly adopts a composite structural design of “metal skeleton + elastic seal.” The inner side is inlaid with a high-pressure resistant fluororubber gasket with a Shore hardness of 75±3, capable of withstanding extreme temperature changes from -40℃ to 150℃, and showing no aging or deformation under 35MPa high-pressure conditions. The gasket and metal frame are integrally vulcanized, achieving a bonding strength of 3MPa, completely solving the industry problem of gasket detachment in traditional pipe clamps.

The pipe clamp base features a widened and thickened design, increasing the contact area by 50% compared to traditional pipe clamps. Combined with precision-machined mounting holes (tolerance grade IT7), the hole positioning accuracy is controlled within ±0.05mm, ensuring a tight fit with the machine mounting surface. The unique anti-loosening bolt assembly (with integrated disc spring washers) effectively counteracts bolt loosening caused by high-frequency vibrations of the equipment, reducing the loosening failure rate by 98% compared to traditional pipe clamps.

Adaptable to all operating conditions, ensuring system stability

This pipe clamp assembly is specifically designed for the multi-scenario operating environment of the XE2000 excavator, maintaining stable performance in extreme environments such as high-altitude mines (above 5000 meters), humid and hot coastal construction sites, and dusty quarries. Its surface employs a dual anti-corrosion process of “zinc-nickel alloy plating + ceramic sealing,” offering three times the corrosion resistance of ordinary galvanized pipe clamps and maintaining structural integrity even in acidic and alkaline environments.

Actual engineering application data shows that XE2000 excavators equipped with this assembly experience a 60% reduction in hydraulic pipeline vibration amplitude, a 90% reduction in pipeline joint leakage rate, and a 95% reduction in downtime due to pipeline problems. In heavy-duty crushing operations in large mines, the pipe clamp assembly effectively absorbs the vibration energy generated by hydraulic shock, reducing the dynamic pressure fluctuation amplitude of the pipeline system by 40%.

Original Factory Precise Fit, Enhanced System Efficiency

As a core original XCMG component, the pipe clamp assembly (part number 804411417) achieves 100% precise matching with the hydraulic piping layout and machine structure of the XE2000 excavator. The assembly’s installation position has been optimized through 3D simulation, evenly distributing pipe stress and preventing fatigue cracking caused by localized stress concentration, thus forming a perfect synergy with the overall hydraulic system.

The installation process adopts a “modular quick-installation” design, requiring no on-site processing or adjustment. Combined with original factory installation tools, installation efficiency is increased by 70% compared to generic pipe clamps. Data shows that using the original factory pipe clamp assembly can extend the maintenance cycle of the XE2000 excavator’s hydraulic system by 100%, reduce overall maintenance costs by 30%, and increase equipment uptime to over 95%. Choosing the XCMG XE2000 genuine pipe clamp assembly (part number 804411417) means selecting pipeline safety guarantees for your heavy equipment that have been proven under extreme working conditions. This ensures that the hydraulic system maintains stable and efficient operation during high-intensity work, creating greater economic benefits and safety for engineering projects.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

318810931 flange blocking plate

1 318811361 1 FLANGE BLOCKING PLATE

2 805139984 4 SCREW M12×60 GB/T70.1-2008

3 804411417 1 FLANGE SEALING

##