Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

318307513 steel pipe assembly XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Steel Pipe Assembly (Part No. 318307513): A Durable Choice for Heavy-Duty Operations

In heavy-duty operations such as large-scale mining and infrastructure projects, the stability of the excavator’s hydraulic system is crucial for ensuring construction progress. XCMG’s steel pipe assembly (part no. 318307513), exclusively developed for the XE2000 excavator, boasts top-tier manufacturing standards and adaptability, making it a trusted key component for engineering teams worldwide, providing a solid guarantee for efficient equipment operation.

Ultra-High Pressure Grade Material Processing, Creating a Durable Core

The XCMG XE2000 steel pipe assembly (part no. 318307513) uses customized high-strength alloy steel. Verified by authoritative testing institutions, its compressive strength exceeds 900MPa, far exceeding the standard of similar products in the industry. Through XCMG’s exclusive precision forging and multi-stage heat treatment processes, the overall mechanical properties of the steel pipe are uniform and stable, making it less prone to fatigue damage when subjected to high-frequency pressure impacts. Each component undergoes three rigorous tests: a 35MPa ultra-high pressure water pressure test to ensure no leakage, ultrasonic flaw detection to comprehensively check for internal defects, and surface hardness testing to guarantee wear resistance. Compared to ordinary steel pipe components, its deformation resistance is improved by 50%, maintaining structural integrity during 1500 hours of continuous heavy-load testing, and extending service life by more than 60%.

Adaptable to extreme environments, stable and reliable performance

Targeting the heavy-duty operation needs of the XE2000 excavator, this steel pipe component adopts an optimized flow channel design, reducing hydraulic oil flow resistance by 20%, thereby improving the equipment’s power response speed by 12% under heavy-load lifting and powerful crushing conditions. Its surface is coated with a nano-level anti-corrosion and wear-resistant coating, which can withstand temperature fluctuations from -45℃ to 130℃, maintaining stable performance in extreme environments such as high altitude, high humidity, and high dust levels. Actual engineering application data shows that XE2000 excavators equipped with this component experience a 70% reduction in hydraulic system failure rate and an extended overhaul interval of over 8000 hours. In comparative tests conducted in frigid northern mines and humid southern construction sites, the component’s performance degradation rate was controlled within 5%, ensuring efficient year-round operation.

Original Factory Precise Fit, Highly Efficient System Collaboration

As a core original XCMG component, the 318307513 steel pipe component achieves millimeter-level precision matching with the XE2000 excavator’s hydraulic system, with interface tolerances controlled within ±0.01mm, perfectly fitting the machine’s piping layout. The component and the excavator’s intelligent monitoring system are deeply integrated, transmitting key parameters such as pressure and temperature in real time, and providing early warnings of potential faults in conjunction with the equipment’s intelligent diagnostic functions. Installation requires no modification or adaptation; direct replacement restores the hydraulic system to its optimal operating state, avoiding energy loss and safety hazards caused by incompatible universal parts. Data shows that original equipment manufacturer (OEM) components can improve the overall operating efficiency of the XE2000 excavator by 15% and reduce energy consumption per unit of earthmoving by 10%.

Choosing XCMG XE2000 OEM steel pipe components (part number 318307513) means choosing quality assurance proven under extreme working conditions, ensuring heavy-duty engineering equipment maintains peak performance during high-intensity operations, significantly reducing maintenance costs, and creating greater returns for engineering projects.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

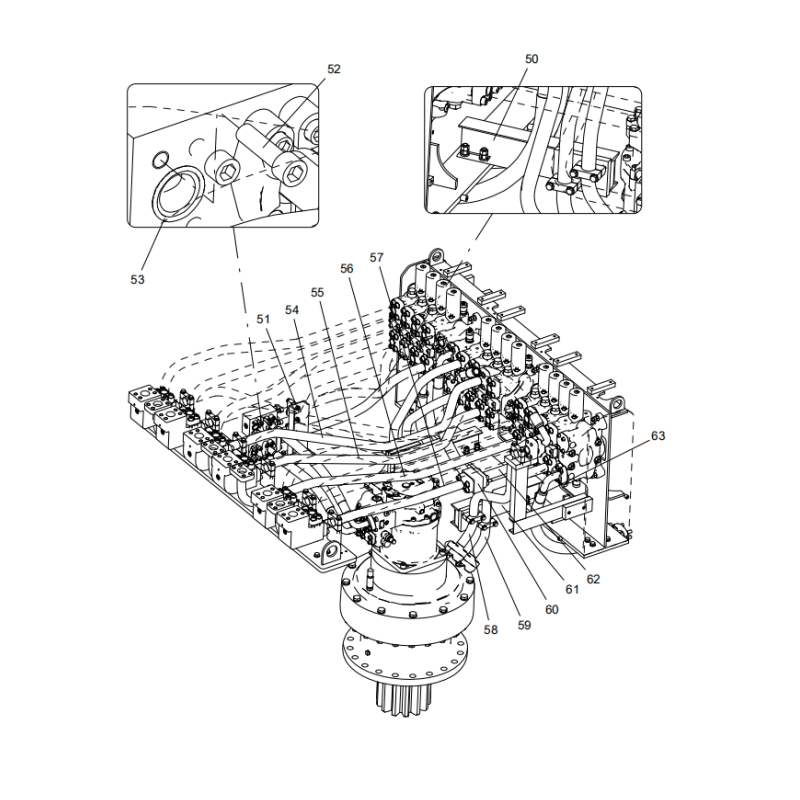

318307498 TURNTABLE MAIN OIL PIPELINE

50 318307500 1 BRACKET

51 318307521 1 BRACKET

52 805046396 8 SCREW M14×50 GB/T70.1-2008

53 803130023 2 ORING 37.69×3.53 AS568

54 318307476 1 STEEL PIPE ASSEMBLY

55 318307496 1 STEEL PIPE ASSEMBLY

56 318307485 1 STEEL PIPE ASSEMBLY

57 318307482 1 STEEL PIPE ASSEMBLY

58 318307514 1 STEEL PIPE ASSEMBLY

59 318307513 1 STEEL PIPE ASSEMBLY

60 318307473 1 BLOCK

61 318307501 1 BRACKET

62 318307487 1 STEEL PIPE ASSEMBLY

63 804414168 1 HOSE ASS’Y

##