When maintaining heavy-duty machinery like shield tunneling machines or mining trucks, ensuring clean transmission fluid is critical. Allison transmission remote filter assembly (29545846) stands out as a kind of high-quality spare part.This paper discusses its unique advantages, technical specifications and top-level applications.

What is Allison Transmission Remote Filter Assembly (29545846)?

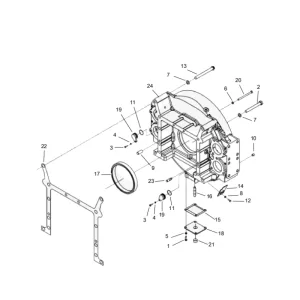

Different from the traditional built-in filters,the Allison transmission remote filter assembly (29545846) uses a remote setting with flexible hoses, allowing installation in limited areas.

Unique Advantages

1.Space – Efficient Installation

Given the extremely limited space of only 0.8 m × 0.6 m in the drive chamber of the cutter head, the 29545846 Allison Transmission Remote Filter Assembly offers a space – efficient solution. By using a 4-meter-long high-pressure hose to install it on the side maintenance platform, it eliminates the complicated and time-consuming need to disassemble the structure of the drive room for replacing the filter.

2.Enhanced reliability and durability

Compared with the previous third-party remote filters, this Allison filter component shows excellent reliability and durability. The high – quality filtration media and robust pipe design contribute to its long – lasting performance, reducing the frequency of maintenance and repair activities.(Source:https://www.iso.org/standard/73700.html)

3.Cost – Effective Maintenance

The extended filter element replacement cycle from 2,000 hours to 4,000 hours significantly reduces the annual replacement frequency, halving the number of filter elements required over a given period.

Product Specifications

| Feature | Detail |

| Model | 29545846 |

| Filtration Accuracy | ≥99.8% (1.5μm+) |

| Temperature Range | -35℃ to 140℃ |

| Max Pressure | 1.5MPa (working), ≥3.8MPa (burst) |

| Flow Rate | 80L/min @ ≤0.18MPa loss |

| Hose Length | 3–5m (customizable) |

| Certifications | CE 2014/30/EU, DOT FMVSS 116, IATF 16949:2016, CNAS L15678, DIN 73378:2020 |

Popular Applications

1. Special Construction machinery (55%)

Core customers include manufacturers of shield tunneling machines and heavy-duty supporting vehicle for mining, such as China Railway Equipment and XCMG Mining. These devices usually integrate the transmissions in a compact bodies, making it difficult to install the traditional filter. The 29545846 remote assembly solves this problem by extending the filter to the side of the equipment through a 3-5 m long pipe.

2. Commercial vehicle modification (28%)

It is mainly used for refitting RV and special logistics vehicles such as refrigerated trucks and dangerous chemicals transport vehicles. The remote filter can be flexibly arranged on the side of the frame to avoid the space conflicts during refitting.

3. Port machinery (17%)

Covers equipment such as container shore cranes and gantry cranes, with customers like Shanghai Zhenhua Heavy Industries. The remote filter can be installed on the equipment platform in a position convenient for maintenance, thus reducing the risk of working at high altitude during maintenance.

Common problems

Q 1:What are the causes of oil leakage in the pipeline of remote filter and how to solve it?

A :Common reasons include: ①The pipe joints are not tightened to the specified torque (standard torque: 22 N・m); ②aging and cracking of pipes (used for more than 3 years);③gasket damage.

Solutions:①Re-tighten the connector to the standard torque with a torque wrench;②check the appearance of the pipeline, and replace it with an original pipeline (model: 29545847) in case of aging or crack;③ replace the fluororubber sealing gasket (model: 29545848), and apply Allison special sealant (model: Allison 1068127) before installation.

Q 2:What should I do if the oil supply of the remote filter is delayed, resulting in insufficient oil pressure when the transmission starts?

A : Troubleshooting steps:①Check if the check valve is stuck (disassemble the check valve, clean the valve core with alcohol, and apply special lubricating grease);②confirm whether the length of the pipeline exceeds 5 m (if it exceeds 5 m, increase the diameter to avoid transmission delay);③check if the filter element is clogged (if the pressure difference ≥ 0.3 MPa, replace the filter element);④in winter, under low temperature, check whether the delay is caused by high viscosity of engine oil (pipeline preheating device can be installed).

Q 3:What are the main operation steps for installing the 29545846 remote filter assembly?

A :①Determine the installation location (reserve a maintenance space of ≥ 20 cm, away from high-temperature parts such as exhaust pipes);② cut the high-pressure pipe into a suitable length (it is recommended to be 10 cm longer than the actual need to avoid excessive stretching);③ the pipe joint adopts “double wrench tightening method” (one wrench is used to fix the joint body and the other wrench is used to tighten the nut to prevent pipe from being twisted);④carry out pressure test after installation (keep the pressure of 1.5 MPa, and do not leak for 30 minutes);⑤start the equipment and idle it for 10 minutes, checking that the oil pressure gauge is stable without significant fluctuations.

Q 4:29545846 How to adjust the maintenance period of remote filter screen under different working conditions?

A :It should be adjusted according to the working conditions:①For normal tunnel/port operations (moderate pollution): replace the filter element every 4000 hours; Check the pipeline seal every 6 months;②for highly polluting operations: replace the filter element every 2500 hours, and check the pipeline every 3 months. Pre-filter is recommended;③for coastal environment with high salt fog: replace the filter element every 3500 hours: and carry out rust prevention treatment on the pipe joints every 4 months;④for extreme low-temperature/high-temperature environments: replace the filter element every 3000 hours and check the check valve and pipe elasticity every 2 months.

Q 5: Can the 29545846 remote filter assembly be compatible with all Allison gearboxes that need to be installed remotely?

A :It needs to be matched according to the transmission displacement:①29545846 is compatible with Allison 3000/4000 series large displacement transmissions (oil flow: 60-100 L/min);②Allison 2000 series small displacement gearbox (oil flow: 40-60 liters/minute) needs 29545849 remote filter assembly;③The pipe diameters and filter element flow rates of the two are different, and using the wrong one will result in excessive pressure loss or insufficient filtration, so the transmission model and oil flow rate parameters must be provided before purchase.

Q 6:What are the advantages of a remote filter compared with the traditional built-in filter? Does it work in all scenarios?

A :Advantages:①flexible installation, suitable for equipment with narrow spaces around the transmission (such as shield machine and modified vehicles);②easy maintenance, and the filter element can be replaced without disassembling the device body;③it can be far away from high temperature/vibration sources, thus prolonging service life.

Application scenarios: equipment with insufficient space around the gearbox, inconvenient maintenance and harsh environment; Inappropriate scene: For equipment with sufficient space and strict restrictions on pipeline layout (such as ultra-small installation clearances), conventional built-in filters (such as 29539579) are more suitable.

Conclusion

By selecting 29545846 Allison Transmission remote filter assembly, the products you invest not only meet but also exceed the industry standards, ensuring the service life and efficiency of Allison transmission. Whether you’re operating in extreme conditions or simply looking for a reliable maintenance solution, this remote filter assembly is your go-to choice.