Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800168973 connecting flange XCMG XE2000 excavator spare parts

Share:

Product Details:

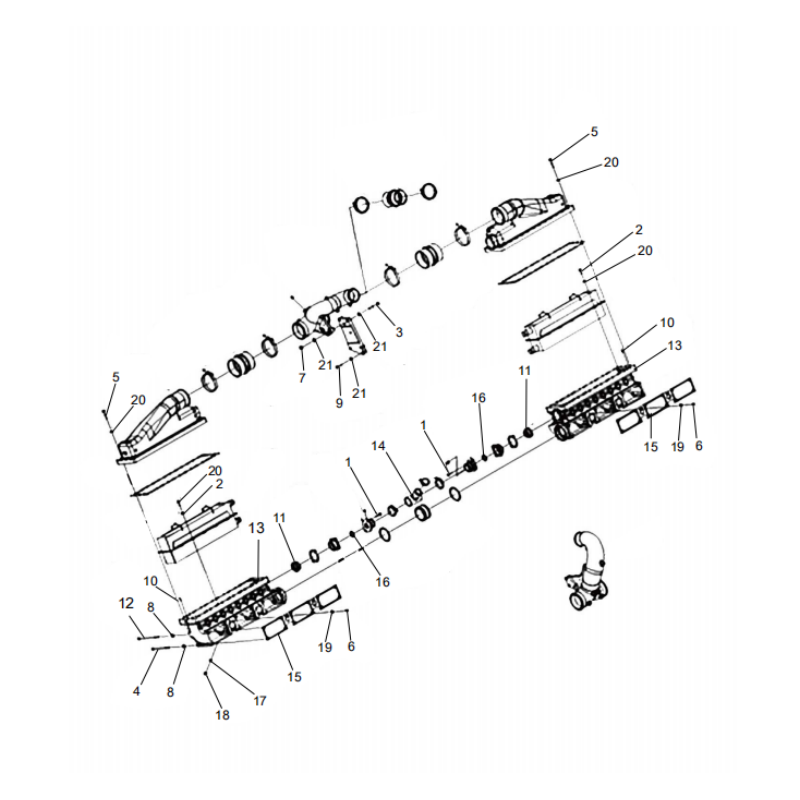

XCMG XE2000 excavator connecting flange (part number 800168973): Sealed and pressure-bearing, ensuring a stable core pipeline connection.

In the hydraulic and cooling fluid piping systems of the XCMG XE2000 excavator, the connecting flange is a core component for achieving precise connection between pipelines and equipment, and between pipelines themselves. Its sealing performance and pressure resistance directly determine the stability of fluid transmission. Once the flange connection fails, it can easily lead to high-pressure leakage, sudden drop in system pressure, and other malfunctions, seriously affecting operational efficiency. This article focuses on the XCMG XE2000 original factory connecting flange (part number 800168973) – a high-pressure connecting flange for excavators specifically designed for this model, which uses precision craftsmanship and reliable performance to build a solid “safety line” for pipeline connections.

Precisely compatible with XE2000: Millimeter-level matching of original piping

This connecting flange (part number 800168973) is custom-made strictly according to the interface parameters, installation spacing, and flange standards of the XCMG XE2000 excavator piping system. The flange outer diameter, number and spacing of bolt holes, and sealing surface flatness perfectly match the original factory design. No additional processing or adjustment of the installation position is required; it can directly connect to the piping interfaces of core components such as hydraulic pumps, cylinders, and radiators. The bolt holes are precisely aligned, and the sealing surfaces fit tightly—avoiding installation jams caused by dimensional deviations and eliminating the risk of leakage due to gaps. As a dedicated piping flange for the XE2000, it forms a highly synergistic connection with the original factory piping and seals, ensuring the stability of the piping connection from the source.

High-strength material: High pressure resistant and corrosion resistant, suitable for heavy-duty working conditions.

Made from high-quality carbon structural steel or stainless steel through forging, and processed with heat treatment and surface anti-corrosion coating, the flange possesses excellent high-pressure corrosion resistance: under high-pressure conditions exceeding 30MPa in the XE2000 excavator hydraulic system, the flange body shows no deformation or cracks and can withstand fluid impact for extended periods; facing the humid environment of construction sites and the corrosive effects of hydraulic oil and coolant, the surface coating effectively blocks corrosive media, preventing the flange from rusting or deteriorating. Compared to ordinary cast flanges, its tensile strength is increased by more than 40%, and its service life is extended by 2 times, easily handling harsh working conditions and high-frequency vibrations in heavy-duty operations.

Precision sealing design: Prevents leakage and ensures system pressure.

The flange sealing surface adopts a “convex face + sealing groove” structure (as per original factory configuration). When used with a dedicated sealing gasket, it forms a double sealing effect: the sealing groove precisely positions the gasket, preventing gasket displacement; the convex face fits tightly with the gasket, completely blocking fluid leakage channels under the force of bolt tightening. Even under the continuous vibration generated by excavator operation, the sealing structure remains stable, preventing loosening of the sealing surface due to vibration. This leak-proof flange structure effectively prevents hydraulic oil and coolant leakage, ensures stable pipeline system pressure, guarantees precise hydraulic action and efficient cooling, and reduces downtime maintenance costs caused by leaks.

Every 800168973 connecting flange must pass XCMG’s four core tests:

Dimensional accuracy inspection: Use a coordinate measuring machine to calibrate the flange outer diameter, bolt hole positions, and sealing surface flatness, with the error controlled within ±0.03mm;

Pressure test: Simulate high-pressure conditions in the pipeline and conduct water or oil pressure tests to ensure that the flange is free from leakage and deformation;

Material testing: The steel composition is verified through spectral analysis to ensure that the material meets the standards and avoids insufficient strength caused by inferior materials;

Corrosion resistance testing: Salt spray test and medium immersion test are conducted to verify the corrosion resistance of the surface coating and ensure that it can adapt to harsh outdoor environments.

Only products that pass all tests will be marked with part number 800168973 before leaving the factory, ensuring that every product received by the user is a reliable original part.

Key function: Supporting the efficient operation of the pipeline system

Hydraulic system: Pipelines connecting the hydraulic pump to the cylinders and valve groups transmit high-pressure oil to ensure strong power output from the boom and bucket;

Cooling system: Pipes connecting the radiator to the engine and hydraulic oil cooler, delivering coolant and maintaining the normal operating temperature of the system;

Structural support: Serving as a “bridge” for pipeline connections, it stabilizes the pipeline route and reduces displacement and wear caused by vibration.

As a core connector in engineering machinery pipelines, the XCMG XE2000 excavator connecting flange (part number 800168973) is an essential accessory for maintaining the quality of original factory pipelines and ensuring efficient excavator operation. Choosing the original factory flange means choosing leak-free connection safety and long-term stable operation.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169252 rear cooler XCMG XE2000 excavator spare parts

22 800167212 SEALRETAINER

23 800161836 O-RING6

24 800161657 COUPLINGGASKET

25 800167120 PIPEPLUG

26 800167007 PIPEPLUG

27 800158237 FLANGEHOSE

28 800169184 AIRCROSSCONNECTIONPIPE

29 800169133 AIRCROSSCONNECTIONPIPE

30 800169154 SUPPORTCONNECTION

31 800169060 DRAINVALVE

32 800169014 AFTERCOOLERCORE

33 800169105 AFTERCOOLERCOVER

34 800158238 TTYPECLAMP

35 800158239 FLANGEHOSE

36 800158240 HOSECLAMP

37 800158241 HOSECLAMP

38 800169139 AFTERCOOLERCOVER

39 800169020 AFTERCOOLERCOVER GASKET

40 800158242 TTYPECLAMP

41 800168973 CONNECTINGFLANGE

42 800169188 AIRBALANCEPIPE

XCMG XE2000 connecting flange

800168973 Genuine parts

Excavator high-pressure connection flange

XE2000 Dedicated Pipeline Flange

Leak-proof flange structure

Core connectors for engineering machinery pipelines