Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800158239 flange hose XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 excavator flange hose (part number 800158239): pressure-resistant and flexible, ensuring efficient fluid transmission.

The core systems of the XCMG XE2000 excavator, such as hydraulics and cooling, rely on stable fluid transmission to maintain operation. As a key component connecting pipelines and equipment, the pressure resistance and sealing performance of flange hoses directly affect the overall machine’s operating efficiency. This article focuses on the XCMG XE2000 original flange hose (part number 800158239) – a dedicated high-pressure flange hose for excavators, providing reliable fluid transmission under heavy-duty conditions.

Precisely compatible with XE2000: Seamless system integration

This flanged hose (part number 800158239) is custom-made to strictly conform to the interface specifications, flange dimensions, and installation spacing of the XE2000 excavator’s fluid piping. The hose length and flange bore diameters at both ends are perfectly matched to the original equipment system. No additional fittings or pipe cutting are required; it can be directly connected to components such as hydraulic pumps and coolers. The flange sealing surfaces fit tightly, eliminating fluid leakage or pressure loss due to mismatches. As a dedicated fluid hose for the XE2000, it ensures seamless integration with the system and rapid restoration of operational capability.

Heavy-duty material: High pressure resistant and wear resistant

It adopts a three-layer structure design of “oil-resistant inner tube + steel wire reinforcement layer + wear-resistant outer coating layer”, which has excellent high-pressure wear resistance.

The inner tube is made of oil-resistant nitrile rubber, which does not swell or crack after long-term contact with hydraulic oil and coolant, and has strong corrosion resistance.

The middle layer is made of high-tensile steel wire braid, which can withstand an explosion pressure of up to 32MPa and can withstand the high pressure impact when the XE2000 is operating at full load, eliminating the risk of hose rupture.

The outer layer is made of wear-resistant synthetic rubber, which can resist the scratches of gravel, dust erosion and temperature fluctuations from -35℃ to 110℃ at the construction site, thus extending its service life.

Flexible transmission: vibration-damping pipeline

The continuous vibrations generated during XE2000 operation can easily lead to loosening of rigid pipeline connections. This flange hose, with its excellent flexibility, can effectively absorb vibration energy, compensate for pipeline installation deviations and component displacements, and reduce the stress on flange interfaces. As a vibration-resistant flange hose, it can prevent premature wear of pipeline joints, reduce leakage failures caused by vibration, maintain stable fluid transmission, and ensure precise hydraulic system operation and efficient heat dissipation of the cooling system.

Every 800158239 flange hose must pass XCMG’s triple quality inspection.

Dimensional inspection: Precisely calibrate pipe length and flange dimensions to ensure consistency with original factory specifications;

Performance testing: The pressure resistance and weather resistance have been verified through 10,000+ pressure cycle tests and temperature aging tests.

Sealing test: Pressure test the sealing performance between the flange interface and the pipe body to eliminate potential leakage risks.

Only qualified products are labeled with part numbers before leaving the factory to ensure reliable use.

Key function: Supporting the efficient operation of the system

Hydraulic system: transmits high-pressure oil to provide stable power for the boom and bucket movements;

Cooling system: delivers coolant, regulates engine and hydraulic oil temperatures, and prevents equipment from overheating;

Protective adaptation: Adapts to complex operating environments, protects pipeline connections, and reduces downtime due to malfunctions.

As a fluid transmission component for construction machinery, the XCMG XE2000 flange hose (part number 800158239) is an ideal choice for excavator maintenance, providing continuous fluid transmission assurance for XE2000 heavy-duty operations.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

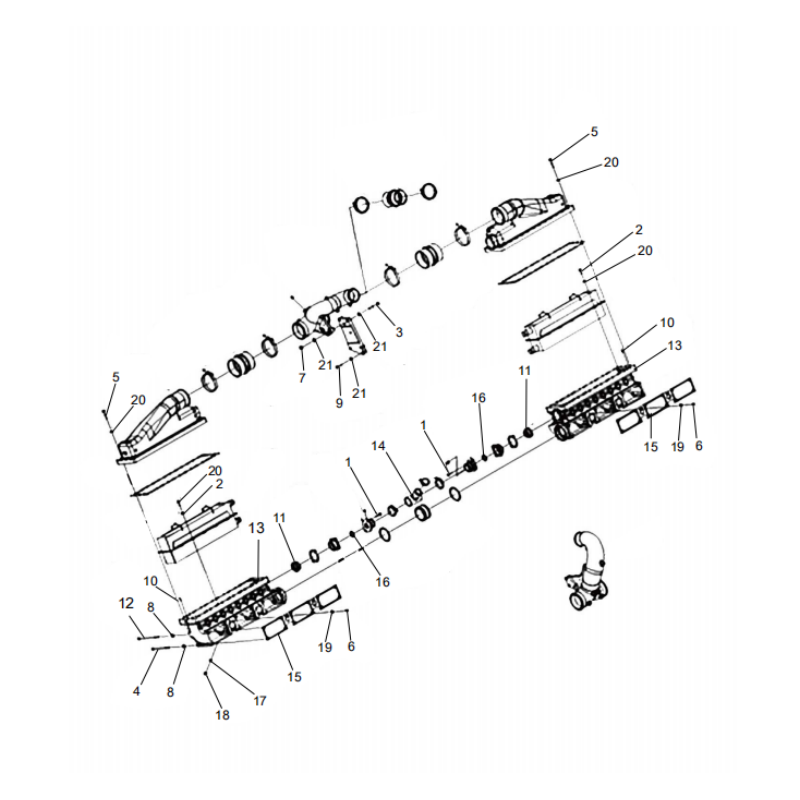

800169252 rear cooler XCMG XE2000 excavator spare parts

22 800167212 SEALRETAINER

23 800161836 O-RING6

24 800161657 COUPLINGGASKET

25 800167120 PIPEPLUG

26 800167007 PIPEPLUG

27 800158237 FLANGEHOSE

28 800169184 AIRCROSSCONNECTIONPIPE

29 800169133 AIRCROSSCONNECTIONPIPE

30 800169154 SUPPORTCONNECTION

31 800169060 DRAINVALVE

32 800169014 AFTERCOOLERCORE

33 800169105 AFTERCOOLERCOVER

34 800158238 TTYPECLAMP

35 800158239 FLANGEHOSE

36 800158240 HOSECLAMP

37 800158241 HOSECLAMP

38 800169139 AFTERCOOLERCOVER

39 800169020 AFTERCOOLERCOVER GASKET

40 800158242 TTYPECLAMP

41 800168973 CONNECTINGFLANGE

42 800169188 AIRBALANCEPIPE

XCMG XE2000 Flange Hose

Excavator high-pressure flange hose

800158239 Genuine parts

XE2000 Dedicated Fluid Hose

Vibration-resistant flange hose

Engineering machinery fluid transmission components