Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800158325 o-ring XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator O-ring 800158325 | Original factory fit, oil-resistant and leak-proof, temperature-resistant and corrosion-resistant, protecting the sealing safety of fluid systems.

For core fluid system components of the XCMG XE2000 excavator, such as hydraulic line interfaces, fuel filter sealing surfaces, and coolant valve assemblies, O-rings serve as the “last line of defense” against leaks. Once the seal fails, it can lead to hydraulic oil loss and system pressure drop, or even component wear and downtime. The XCMG XE2000 genuine O-ring (part number 800158325) is specifically designed for high-seal applications, tightly filling gaps between components and offering oil resistance, temperature resistance, and anti-aging properties. This provides a robust “protective barrier” for the long-term sealing and stable operation of critical systems such as hydraulics and fuel in the XE2000 excavator.

800158325 O-ring: Three core advantages, compatible with XE2000

Original factory precision fit, seamless seal: Dimensions strictly adhere to the XCMG XE2000 fluid system sealing groove design standard, with an inner diameter tolerance ≤0.03mm and wire diameter accuracy controlled within ±0.02mm. The cross-sectional curvature perfectly matches the sealing groove contour, allowing for direct installation without cutting or grinding. Whether it’s a hydraulic pump outlet, fuel line connector, or coolant circulation valve assembly, it perfectly fits the corresponding sealing position, avoiding “sealing blind spots” caused by dimensional deviations, ensuring a seamless sealing structure with components, and compatible with system operating pressures up to 30MPa.

Highly oil-resistant and leak-proof, suitable for multiple media: Made of high-quality fluororubber (FKM), the rubber has a stable molecular structure. After immersion in various media such as hydraulic oil, diesel, and coolant for 168 hours, the volume change rate is ≤8%, and the hardness change is ≤15 Shore A, with no swelling, cracking, or dissolution. With a compression rebound rate of up to 95%, it can maintain elastic tension for a long time, tightly filling the sealing gaps. Even under system pressure fluctuations or temperature changes, it can still achieve a “zero leakage” seal, effectively preventing power loss due to hydraulic oil leakage or safety hazards caused by fuel leakage.

Temperature resistant, corrosion resistant, and durable, adaptable to various working conditions: Temperature range covers -20℃ to 200℃; it does not crack or harden in low-temperature environments, making it suitable for outdoor operations in northern winters; it does not soften or flow under high-temperature conditions and can withstand the high-temperature radiation of engine compartments and hydraulic systems. The surface is treated with an anti-aging coating to resist corrosion from mining dust, construction site moisture, and chemical media, preventing seal failure caused by rubber aging and cracking. Service life exceeds 6000 hours (75% longer than ordinary nitrile rubber O-rings), reducing downtime maintenance costs and operational interruption risks caused by frequent seal replacements.

Stable performance in multiple scenarios, traceable quality, worry-free use.

Whether the XE2000 is engaged in hard rock excavation in a high-dust mining environment (high-load operation of the hydraulic system), heavy-duty operation in muddy conditions at construction sites (risk of multi-media contamination), or long-term outdoor construction in humid and rainy conditions, the 800158325 O-ring can reliably perform its sealing function. Each piece has passed XCMG’s triple rigorous testing (high-pressure sealing test, oil and temperature resistance cycle test, and dimensional accuracy calibration), conforming to the ISO 3601-1 international standard for hydraulic transmission O-rings and the specifications for sealing components in engineering machinery. It supports official traceability (scanning the anti-counterfeiting code on the product packaging can verify authenticity), ensuring safe use without hidden dangers and avoiding system failures, component damage, and other accidents caused by leakage from inferior O-rings.

Select 800158325, protect XE2000 fluid seal.

If you are experiencing hydraulic oil leakage, fuel leakage, or coolant loss on your XCMG XE2000 excavator, or need to replace aged or deformed O-rings, the 800158325 genuine O-ring is the best choice. Its reliable sealing performance ensures a clean and stable fluid system, reduces wear on core components, and helps the XE2000 maintain high-efficiency operation under various high-intensity working conditions, ensuring the smooth progress of engineering tasks.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

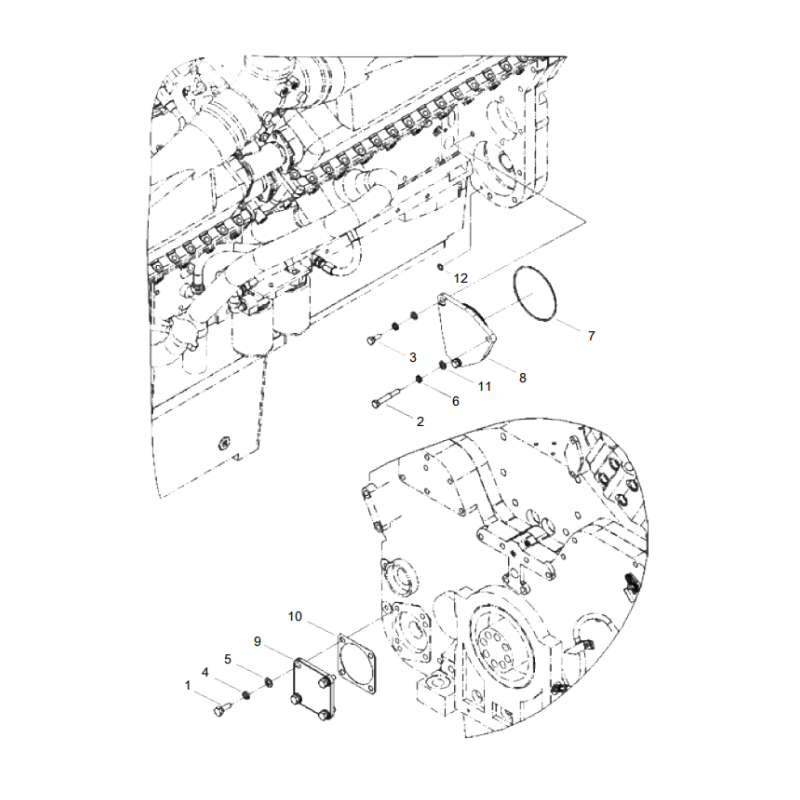

800169244 front-gear drive-system auxiliary drive XCMG XE2000 excavator spare parts

1 800168958 BOLT

2 800169101 BOLT

3 800167065 HEXAGONSCREW

4 800169113 WASHER

5 800169075 WASHER

6 800169180 WASHER

7 800158325 ORING

8 860149587 HYDRAULICPUMPBLINDFLANGE

9 800168946 BLINDFLANGE

10 800167063 GASKETFORHANDHOLE

11 800168926 WASHER

12 800142725 ORING

XCMG XE2000 excavator O-rings

800158325 O-ring

XCMG XE2000 Original O-rings

800158325 Original factory seal

O-rings in excavator hydraulic system

XCMG XE2000 Fluid Leakage Solution

Fluororubber oil-resistant O-rings

High-temperature resistant O-rings

XE2000 excavator fuel system O-ring

800158325 Excavator Parts

O-rings for sealing in mining operations

Hydraulic O-rings for infrastructure construction

High-pressure O-rings for construction machinery

XCMG XE2000 coolant sealing O-ring

Anti-aging excavator O-rings