Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800158277 anti-wear bushing XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Wear-Resistant Bushing 800158277 | Original Equipment Manufacturer, High Hardness and Wear Resistance, Cushioning Protection, Ensuring Long-Term Operation of Vulnerable Parts

In hard rock excavation in mining and heavy-duty construction operations, the XCMG XE2000 excavator is prone to excessive wear in parts such as the boom pin, boom connection point, and slewing bearing due to high-frequency friction and impact. The XCMG XE2000 original wear-resistant bushing (part number 800158277) is a core protective component for high-wear parts. It can form a “wear-resistant buffer layer” between metal parts, preventing scratches and increased gaps caused by direct friction. It builds a solid “protective barrier” for the long-term stable operation of the vulnerable connection parts of the XE2000 excavator.

800158277 Wear-resistant bushing: Three core advantages, compatible with XE2000

Original factory precise fit: The dimensions strictly follow the design standards of high-wear parts of XCMG XE2000. The fit tolerance of inner diameter, outer diameter, length and pin shaft and mounting hole is controlled within 0.01-0.02mm. The inner wall surface finish reaches Ra≤0.4μm. It can be directly press-fitted without grinding, avoiding bushing loosening and component misalignment caused by fit deviation. It ensures tight fit with pin shaft and structural parts, and is compatible with the connection requirements of multiple parts such as stick, boom, and bucket, ensuring accurate and smooth movement trajectory of parts.

High hardness, wear resistance, and impact resistance: Made of special wear-resistant alloy material (containing manganese and chromium alloy components), and subjected to overall quenching and low-temperature tempering treatment, the surface hardness reaches HRC60-65, and the wear resistance is improved by 120% compared with ordinary steel bushings; the inner wall of the bushing is treated with a special honing process to form a micro-convex texture structure, which can store lubricating oil and reduce dry friction loss; it can withstand the high-frequency impact load during excavator operation (maximum impact pressure ≥80MPa), avoiding bushing breakage and deformation caused by impact, and effectively extending the service life of pins and structural components.

Buffering, vibration damping, corrosion resistance and durability: The mating surface between the bushing and the structural components has a built-in elastic buffer layer with a compression rebound rate of ≥90%, which can absorb the vibration energy during component movement and has a vibration attenuation rate of ≥35%, reducing the damage of resonance to the connection parts; the surface is protected by a double coating of phosphate and anti-rust coating, and has passed the salt spray test for more than 400 hours, which can resist the corrosion of mine dust, construction site rainwater and hydraulic oil leakage, and avoid the increase of mating clearance caused by bushing corrosion; the overall service life is more than 10,000 hours (80% higher than ordinary wear-resistant bushings), reducing downtime maintenance costs caused by frequent bushing replacements.

Suitable for multiple scenarios, with traceable quality, and safe to use.

Whether the XE2000 is operating in hard rock mining (high-wear conditions), heavy-duty earthmoving operations in infrastructure (continuous friction loads), or in humid, dusty, and fluctuating outdoor environments, the 800158277 wear-resistant bushing consistently provides stable wear protection. Each bushing undergoes triple testing by XCMG (dimensional accuracy calibration, wear resistance testing, and impact strength testing), conforming to the ISO 13374 standard for wear-resistant bushings and connecting components in engineering machinery. Official traceability is supported, ensuring safe and trouble-free use and preventing malfunctions such as component jamming and structural damage caused by the breakage of inferior bushings.

Select 800158277 to protect high-wear areas of XE2000.

If you are experiencing issues such as abnormal noise from the boom of your XCMG XE2000 excavator, excessive wear on the pins, increased clearance in connection areas, or need to replace aged or damaged wear-resistant bushings, the original XCMG 800158277 wear-resistant bushing is the optimal choice. Its reliable wear resistance and cushioning performance reduce wear in high-wear areas, ensure stable connections, and help the XE2000 maintain its flexible operating capabilities under various high-intensity working conditions, promoting efficient project execution.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

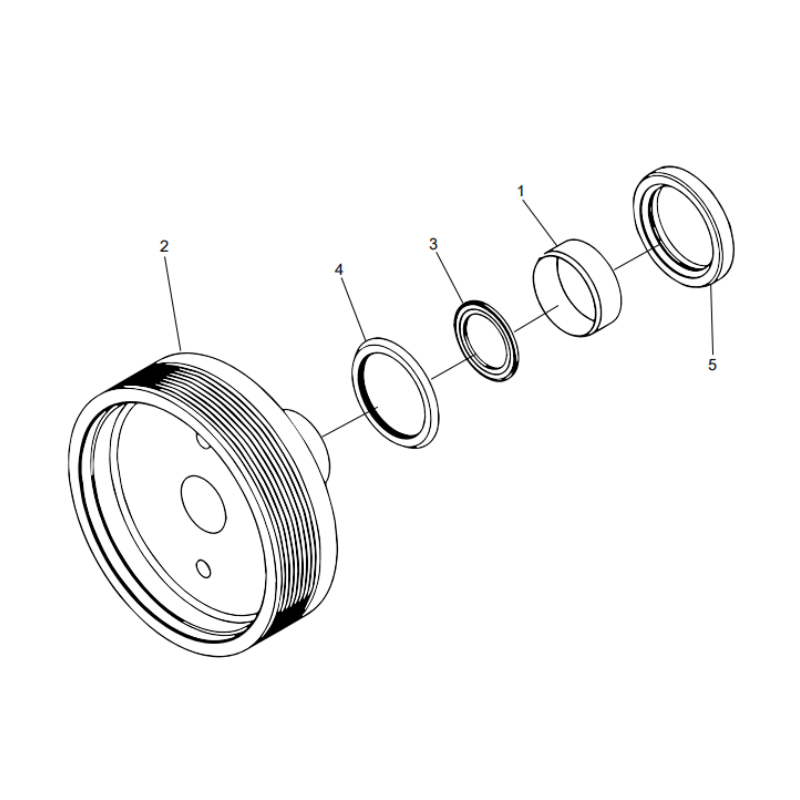

800169256 auxiliary drive device pulley XCMG XE2000 excavator spare parts

1 800158277 ANTI-WEARBUSHING

2 800167194 AUXILIARY DRIVE DEVICE PULLEY

3 800167195 KEYGROOVESEAL

4 800167196 DUSTRING

5 800167197 ORING

XCMG XE2000 excavator wear-resistant bushings

800158277 Wear-resistant bushing

XCMG XE2000 Original Wear-resistant Bushings

800158277 Original protective bushing

Bushings in high-wear parts of excavators

XCMG XE2000 Pin Wear Solution

High hardness wear-resistant bushing

Impact-resistant excavator bushings

XE2000 Excavator Boom Wear-resistant Bushings

800158277 Excavator parts

Wear-resistant bushings for mining operations

Heavy-duty protective bushings for infrastructure

High-hardness bushings for construction machinery

XCMG XE2000 bucket connecting bushing

Corrosion and wear resistant excavator bushings