Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800169087 mounting plate XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Original Mounting Plate (800169087) – A Solid Foundation for Structural Connections

XCMG XE2000 Dedicated Mounting Plate | Part Number 800169087 | High-Precision Positioning and High-Strength Support

In the structural system of the XCMG XE2000 large excavator, the mounting plate (800169087) serves as the mounting base for key components, undertaking important load-bearing and positioning tasks. This original equipment manufacturer (OEM) mounting plate, with its superior strength and precision, ensures stable connections between all components even under extreme working conditions. Choosing an OEM mounting plate is a wise choice to provide reliable structural protection for your equipment.

Why is the original manufacturer’s mounting plate so important?

The mounting plate is the “skeleton connector” of the equipment’s structural system, and its core functions include:

1. Precise positioning: Ensures the accuracy of the installed component positions and guarantees the coordinated operation of the equipment.

2. High-strength support: withstands heavy loads and impacts from the working device, preventing deformation.

3. Vibration buffering: Effectively disperses vibrations and stresses generated during equipment operation.

4. Long-term durability: Fatigue-resistant design extends the overall service life of the equipment.

Four Advantages of Choosing Original Part Number 800169087

1. Precision manufacturing process

The process involves one-time forming using a CNC machining center, with hole tolerances controlled within ±0.1mm to ensure perfect matching with related components.

2. Guaranteed high-quality materials

Using Q345B high-strength steel plate, after heat treatment and surface sandblasting for rust prevention, the tensile strength is increased by 40%.

3. Original factory precise matching

Designed specifically for the XE2000, it is fully compatible with the frame, workpiece, etc., and requires no adjustment during installation.

4. Extreme operating condition verification

Reliability under heavy load conditions is ensured through 1 million fatigue tests and ultimate load tests.

Applicable Scenarios and Replacement Recommendations

•Applicable Models: XCMG XE2000 series excavators

• Original part number: 800169087

• Application areas: Key mounting locations such as engine mounts, hydraulic pump mounts, and valve assembly mounting plates.

• Replacement timing: It is recommended to check for deformation and cracks every 5000 working hours, and replace immediately if any abnormalities are found.

Fault warning signals

If the following situations occur, please check or replace the mounting plate promptly:

• Visible cracks or deformation on the surface of the mounting plate

• The fixing bolts are frequently loose.

• Abnormal vibrations intensify during equipment operation

• Signs of stress concentration were observed at the installation location.

Choose the original manufacturer, benefit for life.

• Structural safety: Ensure that critical components of the equipment are securely installed to prevent structural failures.

• Reduce maintenance: Minimize damage to associated components due to mounting plate issues.

• Maintain Value: Preserve the original performance of the equipment and protect its value as a used device.

Take action now!

[Professional Advice]

During installation, please use a torque wrench to tighten the bolts according to standard torque increments to ensure even force distribution. Regularly inspect the mounting plate, especially after heavy-duty operations. It is recommended to periodically apply anti-rust oil to the mounting plate surface to extend its service life.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169249 rust protection machine XCMG XE2000 excavator spare parts

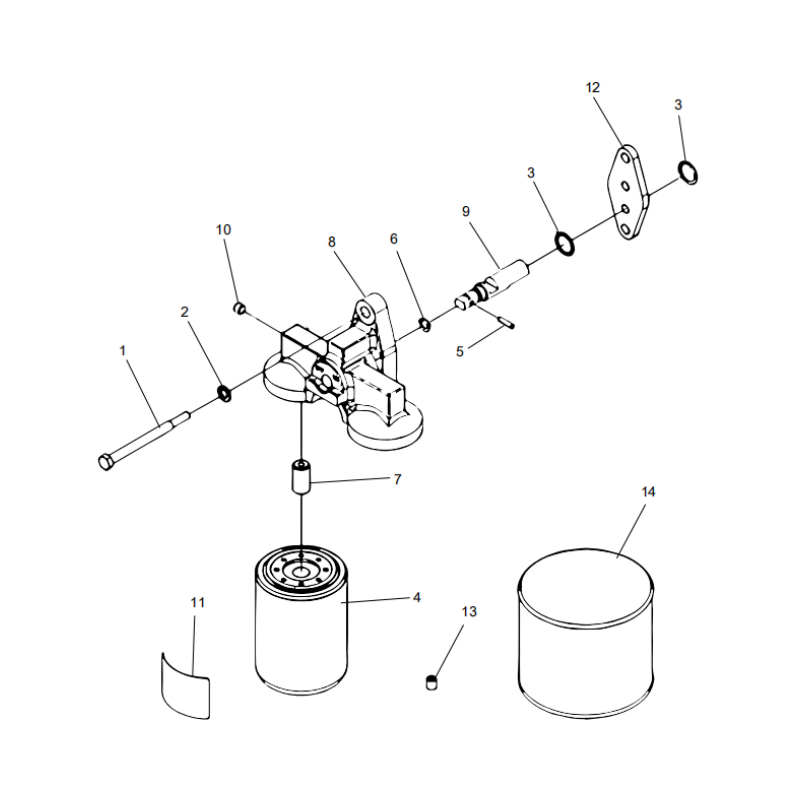

1 800168932 BOLT

2 800138362 MAT

3 860149597 ORING

4 800107886 WATERFILTERELEMENT

5 860149616 ROLLPIN

6 860149596 ORING

7 800168999 FILTER ADAPTER

8 800169191 CONNECTOR

9 800168971 STOPVALVESHAFT

10 800167120 PIPEPLUG

11 800169035 NAMEPLATE

12 800169087 MOUNTINGPLATE

13 800169039 RUSTINHIBITOR

14 800168959 ANTI-CORROSION COOLANT ADDITIVE

XCMG XE2000 mounting plate, 800169087, excavator structural parts, equipment mounting base plate, genuine XCMG parts