Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

860149611 flange gasket XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Flange Gasket 860149611 | Original factory sealing gasket, leak-proof and high-pressure resistant, ensuring efficient equipment operation.

When XCMG XE2000 excavators operate under high-intensity conditions in mines and construction sites, the sealing performance of the flange connections directly affects the overall machine performance. If the flange gasket fails, leading to media leakage, it will not only waste materials but may also cause equipment failure and prolong downtime. The XCMG XE2000 original flange gasket (part number 860149611) is specifically designed to solve this problem. With its superior sealing performance and precise fit, it has become a key component ensuring the stable operation of the XE2000 excavator.

860149611 Flange Gasket: Compatible with XCMG XE2000, three core advantages solve sealing problems

As a large excavator, the XCMG XE2000’s flange connections must withstand high pressure, vibration, and corrosion from complex media, placing extremely stringent requirements on gasket performance. The 860149611 sealing gasket uses XCMG’s original customized formula materials and undergoes multiple processing steps, resulting in superior sealing reliability, durability, and compatibility compared to ordinary gaskets. Specific advantages are as follows:

Superior high-pressure sealing eliminates leakage risks: Designed for the high-pressure operating conditions of the XCMG XE2000 excavator’s hydraulic system and pipelines, the 860149611 flange gasket can withstand a maximum working pressure of 40MPa and maintains excellent elasticity and sealing performance within a temperature range of -30℃ to 100℃. Its sealing surface features a precision-textured design that ensures a tight fit to the flange interface, effectively preventing leakage of hydraulic oil, coolant, and other media. This avoids equipment corrosion and power loss caused by leaks, and reduces maintenance frequency.

Anti-aging and wear-resistant, extending service life: Considering that the XE2000 excavator operates in harsh environments of dust, moisture, and vibration for extended periods, the XCMG XE2000 dedicated flange gasket (860149611) is made of oil-resistant and aging-resistant composite fiber material, with a surface anti-corrosion coating. Compared to the replacement cycle of ordinary gaskets of approximately 2000 hours, this original equipment gasket has a service life of over 4500 hours, with 50% improved wear resistance and 40% enhanced anti-aging performance, significantly reducing equipment maintenance costs and downtime.

Precise original factory dimensions, convenient and error-free installation: As an original factory flange gasket (860149611), its dimensional parameters fully comply with the design standards of the XCMG XE2000 excavator flange interface. The bore diameter, thickness, and outer diameter are precisely matched, eliminating the need for on-site cutting or adjustment. Even novice maintenance personnel can quickly complete the installation, avoiding secondary problems such as seal failure and flange damage caused by incorrect gasket dimensions, improving maintenance efficiency, and ensuring the equipment is back in operation as soon as possible.

Multi-scenario compatibility, full quality traceability, and greater peace of mind when using.

Whether your XCMG XE2000 excavator is used for ore excavation in open-pit mines, earthmoving operations in large-scale infrastructure projects, or material handling at port terminals, the XCMG XE2000 excavator flange gasket 860149611 can adapt to the sealing requirements under different working conditions and consistently perform well. Each gasket undergoes triple quality testing by XCMG before leaving the factory: raw material media resistance testing, high-pressure sealing simulation testing, and dimensional accuracy calibration. Product traceability is also supported, ensuring compliance with the ISO 9001 quality management system and engineering machinery industry sealing standards, completely eliminating your concerns about the quality of the seals.

Choose flange gasket 860149611 now to safeguard your XCMG XE2000.

If you are troubled by flange leakage issues on your XCMG XE2000 excavator, or need to purchase reliable original equipment manufacturer (OEM) gaskets to ensure efficient equipment operation, the 860149611 flange gasket is undoubtedly the best choice. It not only solves the current sealing problem, but also saves you long-term maintenance costs through its long-term durability, allowing your XCMG XE2000 excavator to maintain stable operation in various high-intensity tasks, thus contributing to the efficient progress of your project.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

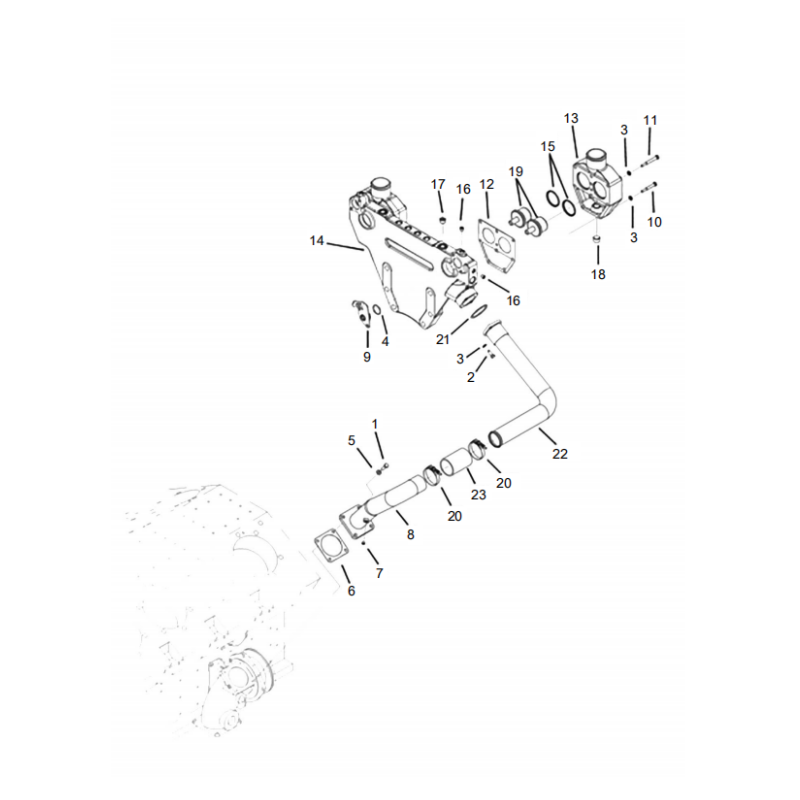

800169264 thermostat seat XCMG XE2000 excavator spare parts

1 800167112 BOLT

2 860135156 BOLT

3 800138362 MAT

4 800142693 ORING

5 800168701 SPRINGWASHER

6 860149611 FLANGEGASKET

7 800167120 PIPEPLUG

8 800168979 BYPASSWATERPIPE

9 800169198 THERMOSTATHOUSINGCOVER

10 800169177 BOLT

11 800169054 BOLT

12 800167215 THERMOSTATCASEGASKET

13 800169005 THERMOSTATSEAT

14 800169193 THERMOSTATSUPPORT

15 800167213 THERMOSTATSEAL

16 800167121 PIPEPLUG

17 800167093 PIPEPLUG

18 800167010 PIPEPLUG

19 860149615 THERMOSTAT

20 800158271 TTYPECLAMP

21 800167644 ORING

22 800168878 WATERDELIVERING PIPE

23 800158244 HOSE

XCMG XE2000 excavator flange gasket

860149611 Flange gasket

860149611 Sealing gasket

XCMG XE2000 Original Flange Gasket

XCMG XE2000 dedicated flange gasket

860149611 Original factory sealing gasket

High-pressure flange gaskets for construction machinery

Excavator flange anti-leakage gasket

Oil-resistant flange gaskets

Flange gaskets for mining operations

Construction sealing gaskets

XCMG excavator maintenance costs

hydraulic system flange gaskets

XE2000 Excavator Sealing Gasket

High wear-resistant flange gasket

XCMG XE2000 Flange Leakage Solution

Excavator flange gasket replacement cycle