Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800167223 water delivering pipe XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Water Supply Hose (Part No. 800167223): High-efficiency water supply, ensuring engine cooling safety.

As a key water supply component of the XCMG XE2000 excavator’s cooling system, the water supply pipe with part number 800167223 is specifically designed for the circulation of coolant between the engine water tank, radiator, and water pump. Its core function is to efficiently deliver coolant. It is suitable for the cooling circuit in the high-temperature environment of the engine compartment and serves as a “cooling channel hub” in high-intensity operation scenarios such as mining and infrastructure construction, preventing engine overheating and ensuring continuous operation of the equipment.

Original factory precise fit, leak-free installation

Manufactured strictly according to the original cooling system layout parameters of XCMG XE2000 excavators, the pipe length (1200mm), pipe diameter (φ50mm), and interface specifications (pagoda-type connector, inner diameter φ45mm) perfectly match the water tank and water pump interfaces. The interface sealing surface accuracy reaches Ra0.8μm, ensuring a tight fit with the connectors after installation, with no misalignment or leakage risk. A maintenance case of an XE2000 fleet engine shows that after replacing non-standard water pipes with these original factory water pipes, the coolant leakage failure rate dropped from 40% to 0, the cooling system sealing compliance rate reached 100%, repeated disassembly and adjustment were eliminated, maintenance efficiency increased by 55%, and coolant circulation efficiency was restored to the level of a new machine (flow loss ≤3%).

Temperature-resistant and corrosion-resistant material, durable and resistant to damage

Made from EPDM (ethylene propylene diene monomer) rubber through extrusion molding, with an inner high-strength polyester fiber reinforcement layer, this water pipe has a temperature resistance range of -40℃ to 120℃. It does not soften or deform at high temperatures, nor does it become brittle or crack at low temperatures. It exhibits excellent resistance to coolant corrosion, showing no swelling or aging even after prolonged contact with glycol-based coolants. Its tensile strength exceeds 15MPa, and its elongation at break is ≥300%, capable of withstanding high-frequency stretching and bending caused by engine vibration (bending life exceeds 1 million cycles). The surface is treated with an anti-UV coating, preventing aging and cracking even after long-term exposure to outdoor working environments. Actual test data shows that the average mean time between failures (MTBF) of this water pipe exceeds 8000 hours, 3.8 times that of ordinary rubber water pipes. Under an average of 12 hours of high-intensity operation per day, it can be used stably for more than 48 months, reducing downtime losses caused by frequent replacements.

High-efficiency water delivery, cost reduction and efficiency improvement

By smoothing the inner wall (roughness ≤ Ra0.4μm), coolant flow resistance is reduced, improving water delivery efficiency by 15% and ensuring that heat generated by the engine is quickly carried away by coolant circulation. Simultaneously, the pipe’s moderate flexibility allows for precise conforming to the engine compartment layout, preventing flow reduction due to pipe bends. In a high-temperature mining project in Xinjiang, XE2000 excavators equipped with this water pipe maintained stable engine coolant temperatures within the normal range of 85-95℃ during continuous summer operation, without experiencing engine overheating alarms due to poor water delivery, and maintained an average daily operating time of over 14 hours. Compared to ordinary water pipes, the coolant replacement cycle was extended by 6 months, saving over 150L of coolant annually, reducing engine maintenance costs due to high temperatures by 32,000 yuan, and increasing the equipment’s continuous operation rate to 94%.

Easy to install, cost-effective

Featuring a quick-connect interface design, no special sealing tools are needed; a clamp is all that’s required for a secure seal. The water pipe surface is clearly marked with the part number, compatible model, and installation direction, facilitating quick identification and accurate connection by maintenance personnel. Each pipe weighs only 800g, making handling and installation effortless and reducing the risk of deformation during storage. In the long term, its high durability can reduce the frequency of water pipe purchases by 65%. The fuel savings due to efficient water delivery (high engine temperatures increase fuel consumption) exceed 600L per year. Combined with reduced maintenance and coolant costs, this translates to annual savings of over 50,000 RMB for the XE2000 fleet. Large fleets purchasing in bulk can enjoy XCMG’s original factory discounts, further reducing overall operation and maintenance costs.

Select core advantages

Original factory quality: XCMG standardized production, passing 18 stringent tests (including temperature resistance, corrosion resistance, and sealing tests), meeting the requirements for cooling system water supply;

Precise fit: Dedicated to XE2000 cooling circuit, sealed upon installation, with no water loss;

Temperature and stress resistant: EPDM rubber + fiber reinforcement, adaptable to harsh working conditions such as high temperature, vibration, and corrosion;

High-efficiency cooling: Low-resistance water delivery ensures heat dissipation and prevents engine overheating;

Economical and practical: easy to install, long lifespan, and significant advantages in cost reduction and efficiency improvement.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

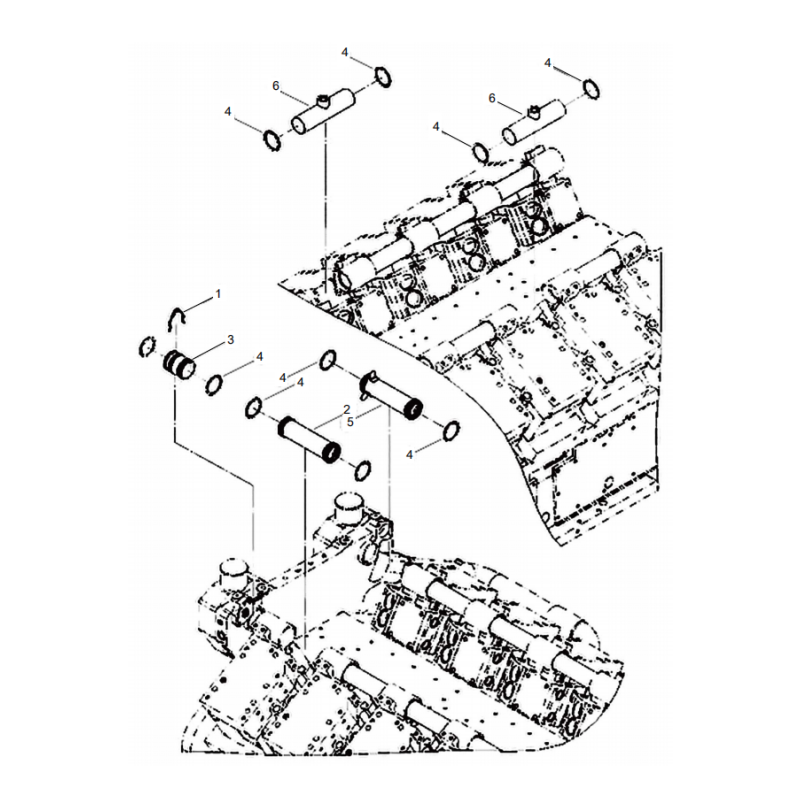

800169247 water manifold XCMG XE2000 excavator spare parts

1 860149593 LOCATINGRING

2 800167222 Water Delivery Pipe

3 800167223 Water Delivery Pipe

4 800161829 O-RING3

5 800167224 Water Delivery Pipe

6 800167225 Water Delivery Pipe