Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

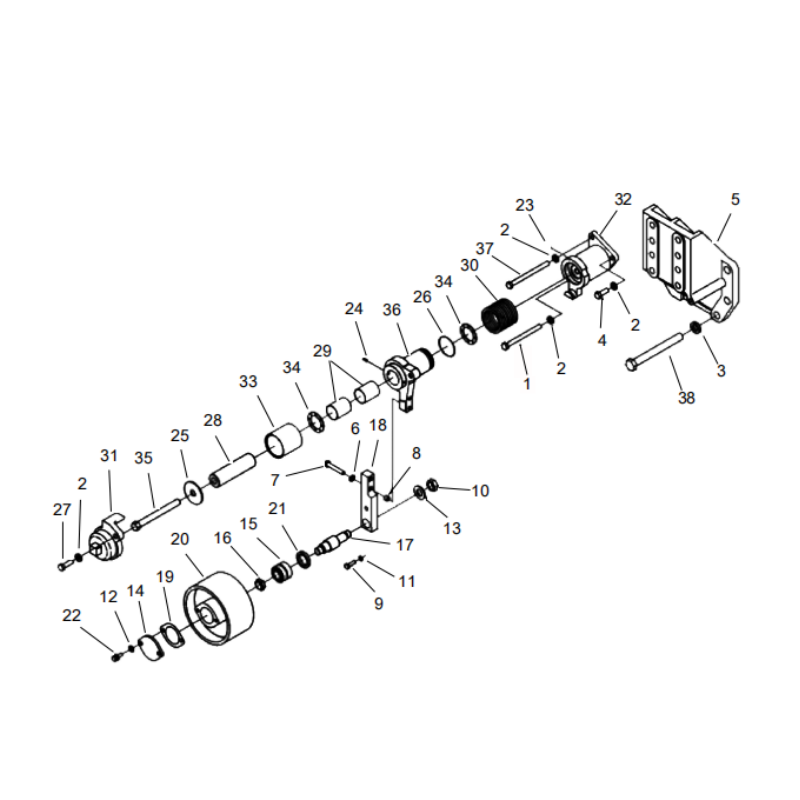

800169103 follower lever XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 excavator driven lever (part number 800169103): Stable force transmission, ensuring efficient operation of the transmission system.

As a key power transmission component in the XCMG XE2000 excavator’s transmission system, the driven rod (part number 800169103) is specifically designed for travel drive and slewing mechanisms. Its core function is to receive power from the active components and accurately transmit it to the actuators. It is suitable for high-frequency force-bearing links such as the connection between the gearbox and the drive axle, and the connection between the slewing motor and the support transmission. It serves as a “power transmission hub” in harsh operating scenarios such as mining and infrastructure construction, ensuring lossless power transmission and preventing transmission interruptions.

Original factory precise fit, installation without deviation

Manufactured strictly according to the original design parameters of the XCMG XE2000 excavator, the diameter (φ45mm) and spacing (320mm) of the connecting holes at both ends match the dimensions of the connecting pins and transmission components with an accuracy of ±0.02mm. The straightness error of the rod body is ≤0.05mm/m. After installation, the coaxiality deviation with upstream and downstream components is controlled within 0.03mm, with no assembly jamming or excessive gaps. A transmission maintenance case of an XE2000 fleet shows that after replacing the aftermarket part with this original factory driven rod, the assembly success rate of the transmission system increased from 80% to 100%, avoiding power transmission deviation caused by dimensional deviations, restoring the transmission efficiency to the level of a new machine (above 98.5%), and reducing assembly time by 45%.

High-strength, torsion-resistant material, durable and resistant to damage.

Made of 42CrMo alloy structural steel through integral forging, key parts undergo quenching and tempering heat treatment (hardness HRC28-32), achieving a tensile strength of 1000MPa and a yield strength exceeding 800MPa. It can withstand instantaneous impact loads (≤80kN) and long-term torque (≤500N・m). The rod surface undergoes medium-frequency quenching and phosphating for rust prevention, with a quenching layer depth of 3-5mm, improving wear resistance by 70% and achieving an IP65 rust prevention rating, preventing rust in rain, dust, and oily environments. It exhibits excellent fatigue resistance, showing no cracks after 1 million cycles of alternating load testing, far exceeding the 500,000-cycle standard of ordinary carbon steel driven rods. Actual test data shows that the mean time between failures (MTBF) of this driven rod exceeds 12,000 hours, four times that of ordinary carbon steel driven rods. Under an average of 12 hours of high-intensity operation per day, it can be stably used for more than 60 months, reducing downtime losses caused by frequent replacements.

Stable power transmission, cost reduction and efficiency improvement

The rod structure was optimized through finite element analysis, and reinforcing bosses were added to key stress-bearing areas, improving stress distribution uniformity by 40% and preventing rod bending or breakage caused by localized stress concentration. Precision bushing mounting positions were built into the connection holes at both ends, perfectly matching the original bearing bushings (e.g., part number 800169298), reducing wear at the connection points and ensuring smooth power transmission. In a coal mine project in Shanxi, XE2000 excavators equipped with this driven rod experienced a reduction in travel drive power transmission loss from 8% to 2%, a 15% increase in slewing response speed, and no transmission interruptions due to driven rod failure. Annual transmission system maintenance costs were reduced by over 50,000 yuan, and the equipment’s continuous operation rate increased to 95%.

Easy to install, cost-effective

No specialized hoisting or positioning equipment is required; assembly can be completed using standard bolts and pins. The driven rod surface is clearly marked with the part number, installation direction, and bolt tightening torque (recommended value 60-75 N·m), facilitating quick identification and standardized operation by maintenance personnel and reducing the risk of incorrect installation. Each rod weighs only 8.5 kg, making handling and installation effortless and preventing deformation during storage. In the long term, its high durability can reduce the frequency of driven rod purchases by 70%, and the efficient power transmission saves over 800L of fuel annually. Combined with reduced maintenance costs, this translates to annual savings of over 80,000 RMB for the XE2000 fleet. Large fleets purchasing in bulk can enjoy XCMG’s original factory discounts, further reducing overall operation and maintenance costs.

Select core advantages

Original factory quality: XCMG standardized production, passing 25 stringent tests (including torsional and fatigue tests), meeting the power transmission requirements of the transmission system;

Precise fit: Dedicated XE2000 drive link, compatible upon installation, with no force transmission deviation;

Robust and durable: Alloy forging + reinforcement treatment, suitable for high load and high impact conditions;

High-efficiency power transmission: Optimized structure + precise adaptation reduces power loss;

Economical and practical: easy to install, long lifespan, and significant advantages in cost reduction and efficiency improvement.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169254 fan drive device bracket XCMG XE2000 excavator spare parts

34 860149577 THRUSTBEARING

35 800169187 BOLT

36 800169103 FOLLOWERLEVER

37 800169001 BOLT

38 800168976 BOLT