Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800169254 fan drive device bracket XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Fan Drive Unit Bracket (Part No. 800169254): Provides stable support and ensures the operation of the drive system.

As a core load-bearing component of the XCMG XE2000 excavator’s fan drive system, the fan drive unit bracket (part number 800169254) primarily functions to fix key components such as the fan drive motor and bearings, ensuring stable power transmission to the fan. It serves as a “solid foundation” in high-intensity work scenarios such as mining and infrastructure construction, maintaining the normal operation of the engine cooling system and preventing displacement and damage to drive components.

Original factory precise fit, installation without deviation

Manufactured strictly according to the original design parameters of XCMG XE2000 excavators, the mounting hole accuracy reaches H7 level, the flatness error of the mating surface with the engine block and fan drive unit is ≤0.03mm, and the fitting gap is controlled between 0.02-0.05mm. Precise alignment of components can be achieved without additional adjustments after installation. A case study of repairing the cooling system of an XE2000 fleet shows that after replacing the non-standard bracket with this original bracket, the assembly deviation rate of the drive unit decreased by 95%, and the coaxiality of the fan and drive motor improved to within 0.04mm, avoiding belt wear or motor noise problems caused by misalignment.

High-strength structure, resistant to loads and durable.

Manufactured from Q345B high-strength steel using CNC cutting and robotic welding, the overall structure has been optimized for mechanical properties through CAE, with reinforcing ribs added to key load-bearing areas. Its bending strength reaches 600MPa, capable of withstanding radial loads (≤8kN) and axial thrust (≤5kN) generated during fan drive system operation. The surface is treated with an electrophoretic anti-rust coating, with over 600 hours of salt spray testing, resisting engine compartment high temperatures (≤180℃), oil stains, and rainwater corrosion. The structure remains stable and undeformed within a temperature range of -40℃ to 160℃. Actual test data shows that its service life is 4.2 times that of ordinary welded steel plate brackets, and it can be stably used for over 40 months under an average of 12 hours of high-intensity operation per day, reducing downtime losses caused by frequent replacements.

Stable support ensures driving efficiency

Precision machining ensures that the perpendicularity error between the mounting surface and the reference surface of the bracket is ≤0.02mm, effectively dispersing the vibration energy of the drive unit and reducing operating noise (vibration amplitude ≤0.5mm). Simultaneously, it provides stable support for the drive motor and bearings, ensuring power transmission efficiency of over 99%. In a low-temperature mining project in Inner Mongolia, an XE2000 excavator equipped with this bracket operated smoothly in the fan drive system after starting in low winter temperatures. No belt slippage or drive failure occurred due to bracket deformation. The engine coolant temperature remained stable within the normal range of 80-92℃, and the average daily operating time was maintained at over 14 hours without interruption of construction due to heat dissipation issues.

Easy to install, cost-effective

No special hoisting or positioning tools are required; installation can be completed using standard bolts. The bracket surface is clearly marked with part numbers, installation baselines, and bolt tightening torque (recommended value 35-45 N·m), facilitating quick identification and standardized operation by maintenance personnel and reducing the risk of incorrect installation. From a long-term cost perspective, its high durability and low failure rate can reduce bracket procurement and replacement expenses for the XE2000 fleet by 48%. For large fleets using it in batches, they can also enjoy XCMG’s original bulk purchase discounts, making the cost advantage even more significant.

Select core advantages

Original factory quality: XCMG standardized production, meeting the stringent support requirements of the heat dissipation system drive unit;

Precise compatibility: Dedicated XE2000 fan driver system, installation error-free;

Robust and load-bearing: High-strength steel + optimized structure, adaptable to harsh working conditions;

High-efficiency drive: Stable support ensures power transmission and improves heat dissipation efficiency;

Economical and practical: easy to install, long lifespan, and reduced overall operation and maintenance costs.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

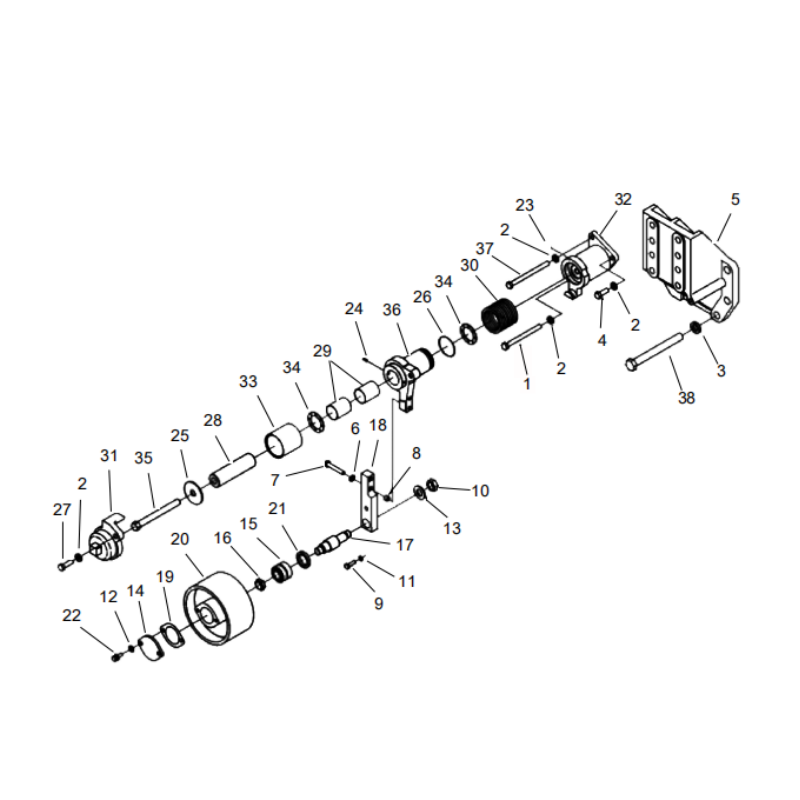

800169254 fan drive device bracket XCMG XE2000 excavator spare parts

1 800167084 BOLT

2 800138361 LOCKINGPLATE

3 860530224 LOCKWASHER

4 860125172 BOLT

5 800168977 FANSUPPORT

6 800138362 MAT

7 800169179 BOLT

8 800167008 DOWELRING

9 800169107 BOLT

10 800168892 NUT

11 860149559 MAT

12 800164686 S626

13 800168904 MAT

14 800169114 IDLERWHEELCOVER

15 800168957 ROLLERBEARING

16 800169132 NUT

17 800168931 IDLERSHAFT

18 800169044 IDLERWHEELBRACKET

19 860149624 FLANGEGASKET

20 800169293 IDLERWHEEL

21 860149573 OILSEAL

22 800168947 BOLT

23 800168886 BUTTERNOZZLE

24 800169029 COLUMNPLUG

25 800169079 MAT

26 860149578 ORING

27 800168908 BOLT

28 860149575 PIVOT

29 860149576 SLEEVEPIPE

30 800169295 TORSIONSPRING

31 800168983 DRIVENBARCOVER

32 800168919 MAINSHAFTSUPPORT

33 800169298 BEARINGBUSHING