Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800168938 connector XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG Original Excavator Connector 800168938 – Core Component for Electrical Signal Transmission in XE2000 Model

If you need to replace the connectors on your XCMG XE2000 excavator, the XCMG original connector (part number 800168938) is the preferred choice. As the “signal bridge” of the XE2000’s electrical system, it is mainly used for the circuit connections of components such as the cab control unit, sensors, and actuators. It bears the critical responsibility of current conduction and signal transmission, and is a core component for construction companies and excavator maintenance teams worldwide to ensure the stable operation of the equipment’s electrical system.

Why choose XCMG XE2000 original connector 800168938?

1. Precise factory fit, seamless installation.

Strictly designed according to the original XE2000 electrical system interface specifications, the number of plug pins, spacing, and housing dimensions are perfectly matched to the equipment interface, requiring no modification to the wiring harness or adjustment of the interface; it can be directly plugged in and unplugged for installation. This avoids the loosening and incompatibility issues caused by dimensional deviations in universal connectors, significantly reducing maintenance time and quickly restoring electrical system connections.

2. Stable transmission with no signal loss.

The pins are made of highly conductive brass with a tin-plated surface, resulting in a contact resistance of less than 5mΩ, ensuring efficient current conduction. At the same time, the pins and sockets are tightly interference-fitted, ensuring stable contact pressure after insertion. Even with high-frequency vibration of the equipment, it can avoid signal interruption or attenuation caused by poor contact, ensuring accurate transmission of sensor data and control commands, and preventing action delays and false alarms caused by signal problems.

3. Waterproof, corrosion-resistant, and highly durable.

The outer shell is injection molded from flame-retardant PA66 engineering plastic and has IP67 waterproof and dustproof performance, which can resist the corrosion of rain, dust and oil stains commonly encountered in XE2000 operations. The interior is equipped with a sealing ring and waterproof terminals to further prevent moisture penetration. It can maintain structural stability even under extreme working conditions of -40℃ to 85℃, and its service life is extended by 60% compared with ordinary connectors, reducing electrical failures caused by connector damage.

4. Vibration-resistant and anti-detachment, safe and reliable.

It adopts a snap-locking structure design, and the snap locks automatically after insertion. The pull-out force is over 150N, which can effectively prevent the connector from accidentally falling off due to equipment vibration or wire harness pulling. At the same time, the outer shell is equipped with reinforcing ribs, which has excellent impact resistance and can withstand the bumps and collisions during excavator operation, avoiding the risk of short circuit caused by the outer shell breaking.

Fully adaptable to various scenarios

The 800168938 connector maintains stable transmission performance in various complex operating scenarios of the XE2000:

Heavy-duty mining operations: Resistant to strong vibration and dust, with stable connection to hydraulic system sensors to ensure accurate feedback of pressure and flow signals;

Infrastructure earthwork construction: Suitable for long-term continuous operation, connected to the cab control harness to ensure real-time transmission of operating instructions and avoid action delays;

Building foundation engineering: resistant to rain and muddy environments, with reliable sealing performance to prevent short circuits caused by moisture infiltration and ensure normal equipment startup;

Agricultural and forestry operation scenarios: It can withstand field dampness and insect infestation, and its shell has strong corrosion resistance. Long-term use will not affect signal transmission efficiency.

800168938 connectors have ample stock and support local allocation and delivery, shortening the supply cycle;

Flexible procurement options: Supports both single retail and bulk wholesale, providing customized quotes for different customers such as repair shops and distributors to meet daily maintenance and bulk inventory needs.

The electrical system of the XCMG XE2000 is the “nerve center” for precise control of the equipment. The original 800168938 connector, with its precise fit, stable transmission, and durable materials, builds a solid “signal transmission defense line” for the electrical system: reducing downtime due to electrical failures, lowering maintenance costs, extending system lifespan, and helping the equipment operate efficiently.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

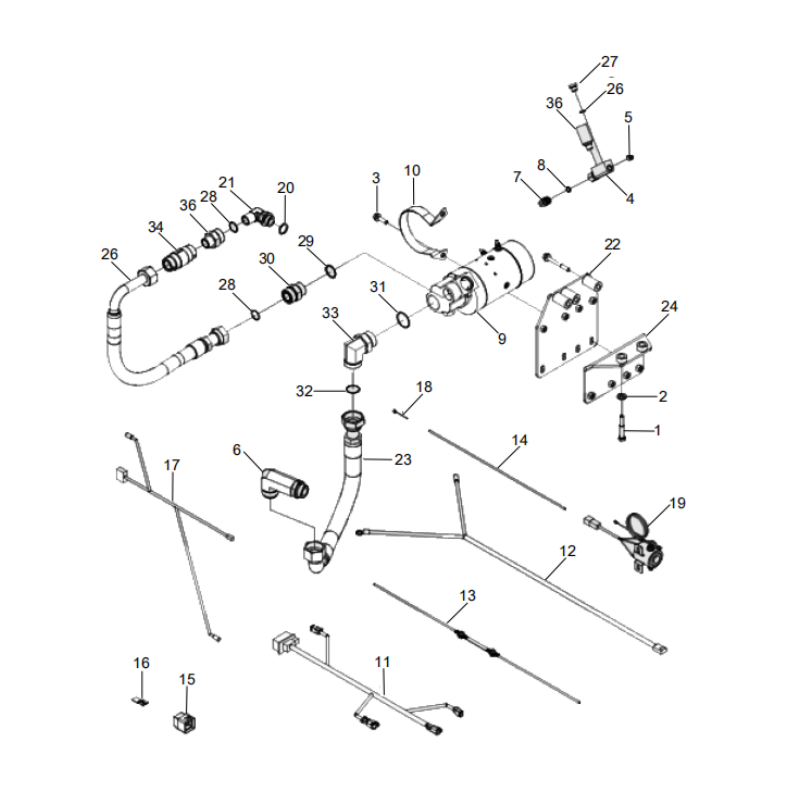

800169259 lubricating pipe XCMG XE2000 excavator spare parts

1 800167126 BOLT

2 860149552 LOCKINGPLATE

3 800169032 BOLT

4 800169195 MULTI-INTERFACE ADAPTER

5 800167121 PIPEPLUG

6 800169077 CONNECTOR

7 800168916 CONNECTOR

8 860149541 ORING

9 800159792 LUBRICANTPUMPBODY

10 800169137 PUMPBRACKET

11 800168936 HARNESS

12 800168988 HARNESS

13 318601418 PRE-LUBRICATION MOTOR POWER CABLE (300A)

14 800168996 BATTERYWIRE

15 318601417 PRE-LUBRICATION CONTROL RELAY

16 800169047 RELAYBRACKET

17 800169007 HARNESS

18 800169066 BATTERYWIRE

19 318601420 PRE-LUBRICATION RELAY

20 800158289 ORING

21 800169109 EXTERNALSCREWTHREADELBOW

22 800168906 PUMPSUPPORT

23 800169164 HOSE

24 800168920 PUMPSUPPORT

25 800169097 HOSE

26 800143982 ORING

27 800143983 SCREWPLUG

28 800158292 ORING

29 800158293 ORING

30 800168938 CONNECTOR

31 800158290 ORING

32 800158296 ORING

33 800168989 CONNECTOR

XCMG XE2000 connector, part number 800168938, XCMG genuine excavator electrical accessories, XE2000 signal transmission connector, XCMG 800168938, XE2000 excavator repair connector, XCMG excavator connector