Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800169290 locating ring XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Positioning Ring (Part No. 800169290): Precise Positioning Guarantee for Precision Components

The XCMG XE2000 mining excavator, with its 192,000kg operating weight, 810kW imported engine, and 10-14m³ bucket capacity, demonstrates superior performance in heavy-duty mining operations worldwide. The positioning ring (part no. 800169290), as a precision positioning device for the core component of the equipment, is a key foundational component ensuring the concentric assembly and coordinated operation of related components, directly affecting the operating accuracy and service life of precision mechanisms such as the engine and hydraulic system.

This positioning ring is precision-machined from high-strength alloy structural steel, possessing excellent dimensional stability and structural rigidity. It maintains stable positioning performance in the vibration, high temperature, and dusty environments of mining operations, effectively resisting deformation or displacement under external forces, avoiding problems such as accelerated component wear and seal failure caused by positioning deviations, and providing durable and reliable positioning support for the precise assembly of precision components. In terms of design, it was specifically developed based on the assembly parameters of the XE2000 core components. The inner diameter accuracy, outer diameter dimensions, and thickness tolerances have undergone multi-dimensional calibration and optimization. Employing a high-precision fit design, the clearance between the ring and related components is controlled within the range of 0.005-0.01mm, precisely limiting the radial displacement and axial movement of components and ensuring that the concentricity error after assembly does not exceed 0.01mm, laying the foundation for efficient collaborative operation of the components.

Relying on XCMG’s advanced manufacturing processes, this positioning ring undergoes rigorous precision machining and quality inspection. The inner and outer circular surfaces are machined using ultra-precision grinding, with a roughness controlled within 0.4μm, ensuring a tight fit with the mating components. Through a tempering heat treatment process, the body hardness reaches 30-35HRC, possessing sufficient strength and good toughness to meet the mechanical requirements of long-term positioning support. Each positioning ring undergoes strict dimensional inspection and roundness testing to eliminate machining defects such as ellipticity and taper. The performance of the positioning ring directly affects the operating efficiency and reliability of precision components. In critical assembly areas such as engine cylinder liners and cylinder blocks, and hydraulic pump rotors and housings, it ensures uniform clearance between components through precise positioning, reducing frictional losses and vibration noise during operation. Its stable positioning ensures uniform force on seals, improving sealing performance and reducing the risk of oil leakage. Simultaneously, precise concentricity control extends the service life of precision components such as bearings and gears, reducing equipment maintenance costs.

Choosing the XCMG XE2000 excavator positioning ring (part number 800169290) not only provides you with a high-quality, durable, and reliable basic component with precise positioning, but also allows you to enjoy timely parts supply and professional technical support through XCMG’s global service network. Let the precise positioning of this precision component lay a solid foundation for the precise operation of your mining equipment, contributing to efficient and stable production.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

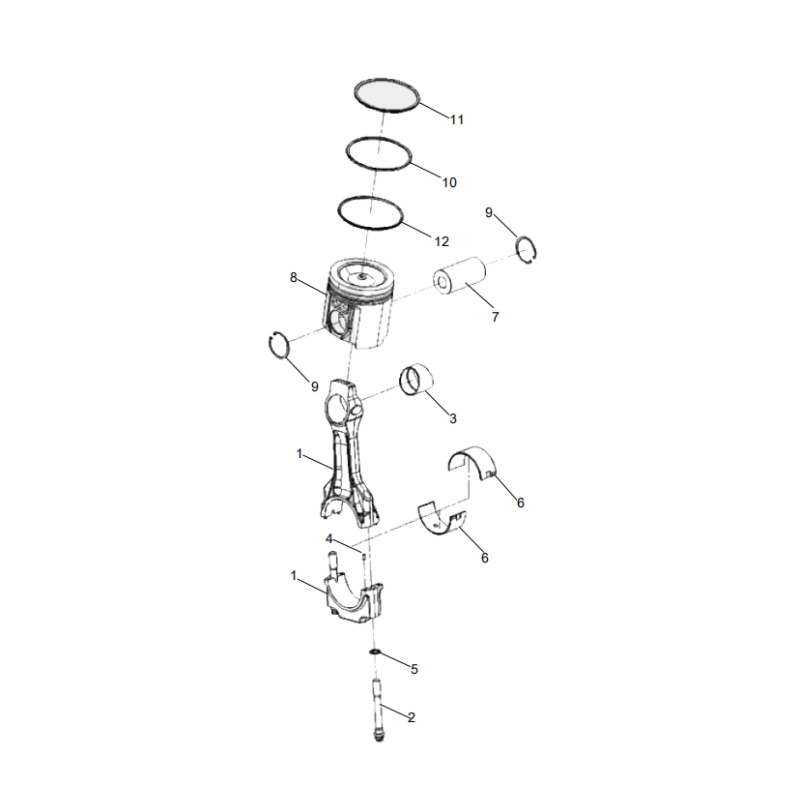

800169282 connecting rod and piston XCMG XE2000 excavator spare parts

1 800168935 12 ENGINE CONNECTING ROD

2 800169294 2 BOLT

3 800169297 1 BUSH

4 800167113 4 SET PIN

5 800166987 2 MAT

6 800158202 2 CONNECTING ROD BEARING

7 800169116 1 PISTON PIN

8 800169037 1 ENGINE PISTON

9 800169290 2 LOCATING RING

10 800169173 1 PISTON RING

11 800169011 1 PISTON RING

12 800169096 1 ENGINE OIL PISTON RING