Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800167055 roll pin XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Needle Roller (Part No. 800167055): A Key Wear-Resistant Support Component for Precision Transmission

The XCMG XE2000 mining excavator, with its 192,000kg operating weight, 810kW imported engine, and 10-14m³ large bucket capacity, demonstrates efficient transmission performance in heavy-duty mining operations worldwide. The needle roller (part no. 800167055), as a core support component of the equipment’s precision transmission system, is crucial for achieving efficient force transmission between shaft parts and bearings, directly affecting the stability of the machine’s power transmission and the service life of its components.

This needle roller is manufactured using high-purity, high-carbon chromium bearing steel through a precision rolling process, possessing extremely high hardness and uniform material density. Through rigorous heat treatment processes, the core hardness reaches 58-62 HRC, and the surface hardness is even higher at 62-65 HRC. Combined with ultra-precision grinding, the surface roughness is controlled within 0.08 μm, ensuring excellent wear resistance even under high-intensity friction environments. Facing the high-frequency impact loads and continuous friction of transmission systems in mining operations, it effectively resists wear, deformation, and fracture, avoiding increased transmission clearance or jamming problems caused by needle roller failure.

In terms of design, it was specifically developed based on the structural parameters of the XE2000 transmission components, with length, diameter tolerances, and cylindricity calibrated in multiple dimensions. Utilizing an optimized length-to-diameter ratio design, it maximizes the contact area within a limited installation space, capable of withstanding radial loads up to [specific value] kN, evenly distributing the force on shaft parts and reducing localized stress concentration. The ends of the needle rollers are rounded to reduce stress wear when in contact with the flanges, minimizing operating noise and energy loss.

Relying on XCMG’s advanced manufacturing technology, this needle roller undergoes stringent quality control and performance testing. Automated sorting equipment ensures that the dimensional deviation of needle rollers in the same batch is controlled within 0.002mm, guaranteeing uniform stress after assembly. Each needle roller undergoes magnetic particle testing and eddy current testing to completely eliminate internal cracks, inclusions, and other quality hazards. The surface undergoes special lubrication treatment to improve lubrication during initial operation and reduce wear during the break-in period.

The performance of the needle rollers directly affects the efficiency and reliability of the transmission system. In key transmission components such as the excavator’s slewing bearing and travel reducer, it effectively reduces pressure per unit area through line contact force distribution, reduces the coefficient of friction, and improves power transmission efficiency. Stable support performance ensures the concentricity of shaft components, reduces vibration and misalignment, lowers the wear rate of related components, extends the overhaul cycle of the transmission system, and reduces equipment maintenance costs.

Choosing XCMG XE2000 excavator needle rollers (part number 800167055) not only provides you with high-precision, wear-resistant, and durable transmission components, but also allows you to enjoy timely parts supply and professional technical support through XCMG’s global service network. Let this wear-resistant support component of precision transmission lay a solid foundation for the efficient operation of your mining equipment’s transmission system and help ensure continuous and stable production.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169284 damper XCMG XE2000 excavator spare parts

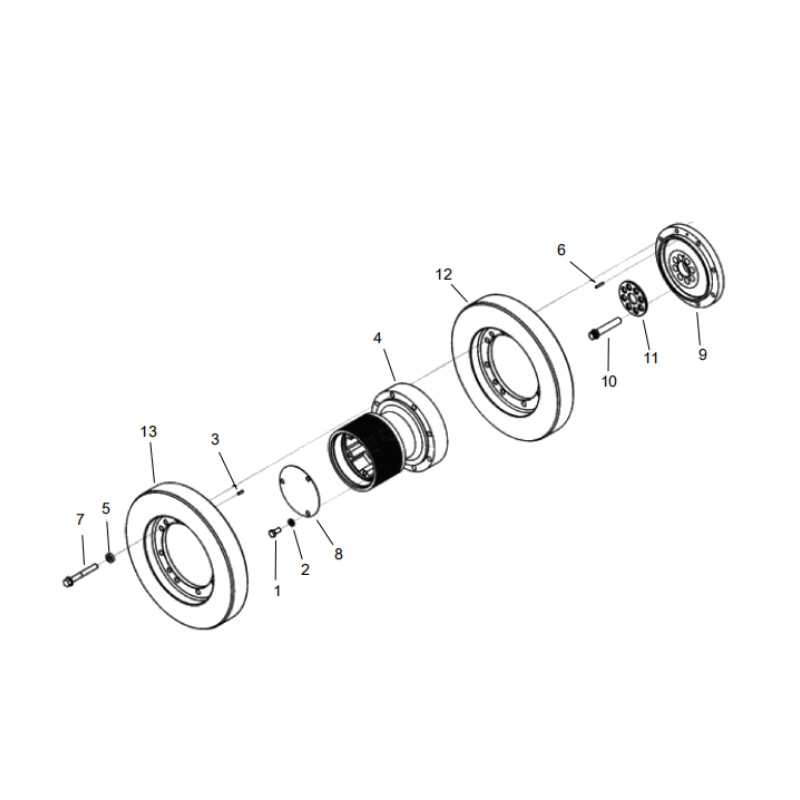

1 800168997 3 BOLT

2 800167052 3MAT

3 800144926 1 ROLLING NEEDLE

4 800169071 1 CRANKSHAFT BELT PULLEY

5 800167053 8MAT

6 800167055 1 ROLL PIN

7 800167056 8 BOLT

8 800167057 1 PROTECTION COVER

9 800167058 1 CRANKSHAFT ADAPTER

10 800167059 8 BOLT

11 800167060 1 CRANKSHAFT GASKET

12 800168975 1 VISCOUS DAMPING ABSORBER

13 800167062 1 VISCOUS DAMPING ABSORBER