Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

800167052 mat XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Gasket (Part No. 800167052): A Sealing and Protective Barrier for Core Components

The XCMG XE2000 mining excavator, with its 192,000kg operating weight, 810kW imported engine, and 10-14m³ bucket capacity, continues to demonstrate its robust performance in heavy-duty mining operations worldwide. The gasket (part no. 800167052), as a key sealing component connecting core parts of the equipment, is crucial for ensuring oil and gas sealing and protecting components, directly impacting the safety and stability of the entire machine’s operation.

This gasket is made of a composite of high-performance oil-resistant rubber and high-strength fiber substrate, manufactured using a precision molding process, possessing excellent sealing elasticity and structural stability. Facing long-term immersion in highly corrosive media such as hydraulic oil and fuel oil in mining operations, as well as alternating high and low temperature environments ranging from -30℃ to 120℃, it maintains stable physical properties, effectively resisting aging and hardening, ensuring a long-term tight seal and eliminating the risk of media leakage. In terms of design, it was specifically developed based on the structural parameters of key connection parts in the XE2000 engine or hydraulic system. The sealing surface contour, thickness, and mounting positioning holes have all been calibrated using 3D scanning. Through optimized cross-sectional curvature design, it can form a uniform compression under bolt tightening pressure, fully filling the connection gaps and maintaining a reliable seal even under high-frequency vibration conditions, avoiding leakage problems caused by micro-gaps.

Relying on XCMG’s strict manufacturing standards, this gasket has undergone multi-dimensional performance verification. It passed a 72-hour oil immersion test, with the volume change rate controlled within 5%; it passed 100,000 vibration fatigue tests, with no degradation in sealing performance; the surface features a micro-protrusion texture treatment, improving adhesion to metal contact surfaces and reducing the risk of assembly misalignment. Each batch of products undergoes random sealing inspection to ensure consistent factory quality.

The reliable performance of the gasket directly affects the operating efficiency of the core equipment system. In engine blocks and oil pans, it effectively prevents oil leakage, ensuring sufficient lubrication. In hydraulic valve groups and pump connections, it prevents high-pressure oil leakage, maintaining stable system pressure. Simultaneously, its barrier function prevents external dust and mud from entering components, reducing the probability of wear and tear and extending the service life of valuable components such as the engine and hydraulic pump.

Choosing the XCMG XE2000 excavator pad (part number 800167052) not only provides you with a precisely matched, reliably sealed, high-quality protective component, but also allows you to leverage XCMG’s global service network for timely parts replenishment and professional technical support. Let this core component’s sealing and protective barrier build a solid safety barrier for your mining equipment, ensuring uninterrupted and efficient production.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

800169284 damper XCMG XE2000 excavator spare parts

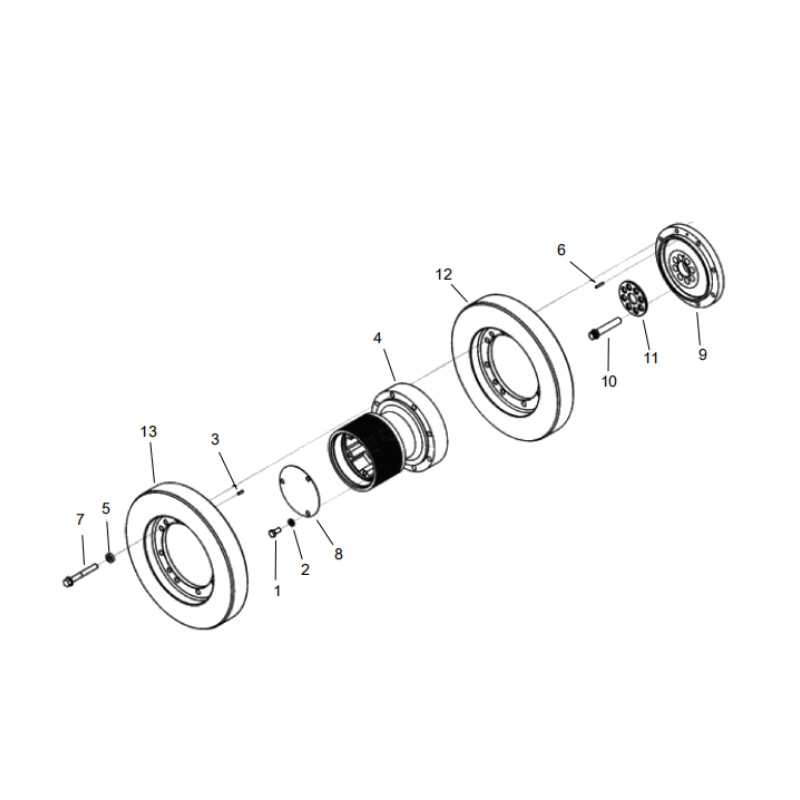

1 800168997 3 BOLT

2 800167052 3MAT

3 800144926 1 ROLLING NEEDLE

4 800169071 1 CRANKSHAFT BELT PULLEY

5 800167053 8MAT

6 800167055 1 ROLL PIN

7 800167056 8 BOLT

8 800167057 1 PROTECTION COVER

9 800167058 1 CRANKSHAFT ADAPTER

10 800167059 8 BOLT

11 800167060 1 CRANKSHAFT GASKET

12 800168975 1 VISCOUS DAMPING ABSORBER

13 800167062 1 VISCOUS DAMPING ABSORBER