Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

329900503 pipe clip XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Pipe Clamp (Part No. 329900503): Precise Clamping for Safe Pipeline Operation

In the piping system of the XCMG XE2000 excavator, pipe clamps are core fixing components that maintain the orderly arrangement of pipelines and prevent vibration damage. The pipe clamp with part number 329900503 is custom-designed for the critical pipelines of the XE2000 excavator. With its superior structural strength and clamping stability, it provides solid support for the safe operation of the equipment’s pipelines under complex working conditions.

This pipe clamp is made of high-strength alloy steel through precision forging. The overall structure has undergone stress relief treatment, giving it significantly higher resistance to deformation and load-bearing capacity than ordinary pipe clamps. Facing the high-frequency vibrations, heavy-load impacts, and collisions from the external environment during XE2000 excavator operation, the 329900503 pipe clamp maintains a stable structural shape, firmly locking core pipelines such as hydraulic and fuel lines. This effectively prevents problems such as loosening of interfaces and pipe wall wear caused by pipeline displacement due to shaking, reducing the risk of pipeline leakage at its source and ensuring the continuity of power transmission and media circulation.

In terms of clamping precision, the clamping groove curvature of the 329900503 pipe clamp has been optimized through 3D modeling to achieve a micron-level fit with the outer diameter of the corresponding pipelines on the XE2000 excavator. Combined with high-strength anti-loosening bolts, it generates a uniform and durable circumferential force, preventing loosening and slippage in long-term vibration environments, ensuring that the pipeline remains in the preset installation position. The inner side of the pipe clamp is inlaid with oil-resistant and wear-resistant rubber gaskets, which not only increase the coefficient of friction to enhance the fixing effect but also absorb vibration energy through elastic buffering, avoiding rigid contact between metal and pipelines and significantly extending the service life of the pipelines. In terms of structural design, this pipe clamp adopts a one-piece stamping process, eliminating weak weld points and resulting in higher overall strength. The bottom mounting holes are precisely machined to perfectly match the holes on the XE2000 excavator’s mounting base, achieving precise alignment without additional adjustments during installation. All edges of the pipe clamp are rounded to completely eliminate sharp burrs, preventing scratches on the pipes during installation and reducing safety risks for operators during maintenance. Its compact layout allows for flexible installation in areas with dense piping, resulting in neater pipe arrangements and ample operating space for future maintenance.

Regarding compatibility, the pipe clamp with part number 329900503, as an XCMG original equipment manufacturer (OEM) certified accessory, is highly compatible with the fixing requirements of critical components such as multi-way valve pipes and engine peripheral pipes on the XE2000 excavator. Whether for the strong fixing of high-pressure rigid pipes or the buffer positioning of flexible hoses, it delivers ideal clamping performance. The installation process requires no modifications to the equipment structure; simply tighten the bolts according to the original factory torque standard to complete the fixation, significantly shortening maintenance and replacement time and helping the equipment quickly return to operational status.

In terms of environmental adaptability, the 329900503 pipe clamp performs exceptionally well. Its surface is treated with a multi-layer composite anti-corrosion coating, achieving over 1500 hours of salt spray testing. It effectively resists corrosion from harsh environments such as high dust levels in mines, high humidity in wetlands, and high salt spray in coastal areas, making it resistant to rust and corrosion over long-term use. The rubber gasket uses an oil-resistant and aging-resistant formula, maintaining stable elasticity within a temperature range of -40℃ to 120℃, ensuring reliable protection even under extreme working conditions.

When you need to replace pipe clamps on your XCMG XE2000 excavator, choosing the original product with part number 329900503 means choosing long-term protection for your pipeline safety. With its robust structural strength, precise clamping performance, and excellent environmental adaptability, it safeguards the excavator’s pipeline system, reducing downtime losses caused by pipeline failures, allowing you to work with peace of mind in various high-intensity construction scenarios and fully guaranteeing project progress.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

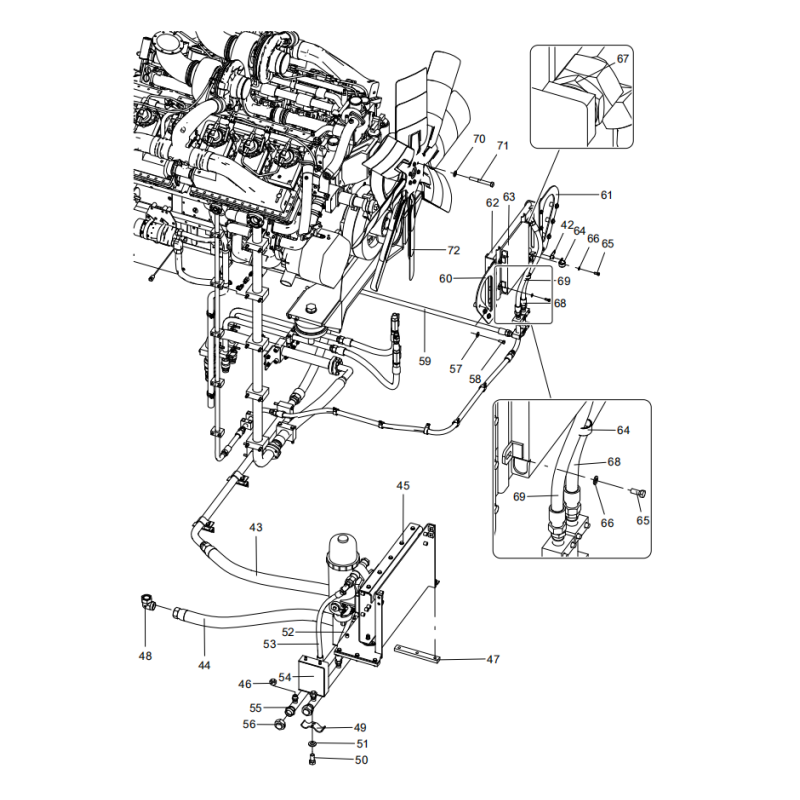

318306873 Engine mounting assembly XCMG XE2000 excavator spare parts

42 318306805 1 BRACKET

43 800171719 1 DIESEL PIPE

44 800166878 1 DIESEL PIPE

45 318300827 1 FUEL FILTER INSTALLATION

46 803177599 4 PLUG

47 318307383 2 PAD

48 803301445 2 CONNECTOR

49 329900503 2 PIPE CLIP

50 805046469 28 BOLT M12×25 GB/T5783-2000

51 805338281 28 WASHER 12 GB/T97.1-2002

52 800175192 1 DIESEL PIPE

53 803419817 1 HOSE ASS’Y

54 318800855 2 STEEL PIPE BRACKETA

55 318800843 2 OIL INLET STEEL PIPEA

56 803173882 2 PLUG

57 329900298 6 THICKENED LARGE WASHER

58 329901414 6 BOLT

59 803419820 1 HOSE ASS’Y

60 318306785 1 BRACKET

61 318306786 1 BRACKET

62 318300819 1 BRACKET

63 800152621 1 FUEL RADIATOR

64 803697900 8 IMPREGNATED HOOP

65 805011330 4 BOLT M10×25 GB/T5783-2000

66 805338279 4 WASHER 10 GB/T97.1-2002

67 800151146 2 CONNECTOR

68 800175156 1 DIESEL PIPE

69 800175154 1 DIESEL PIPE

70 318300796 6 WASHER

71 318300795 6 BOLT

72 800157257 1 FANS