Product

Blogs List

How to Find the Best Allison Transmission ...

2025-11-05 Comments Off on How to Find the Best Allison Transmission Spare Parts Supplier in China?Need More Information?

We’re happy to help you find the best option for your application.

803165999 connector XCMG XE2000 excavator spare parts

Share:

Product Details:

XCMG XE2000 Excavator Connector (Part No. 803165999): Stable Connection, Ensuring Efficient System Collaboration

In the electrical and hydraulic systems of the XCMG XE2000 excavator, connectors are key interface components for signal transmission and media flow between parts. The connector with part number 803165999 is specifically designed for the core system connections of the XE2000 excavator, providing reliable assurance for the efficient collaborative operation of all systems with its superior connection stability and sealing performance.

This connector is precision-manufactured using high-quality alloy materials and engineering plastics. Its main structure undergoes high-strength treatment, possessing excellent impact resistance and structural stability. Facing the continuous vibration, alternating high and low temperatures, and dust and oil contamination encountered during XE2000 excavator operation, the 803165999 connector maintains a stable connection, effectively preventing problems such as poor contact and loosening of the interface caused by external environmental influences. This ensures continuous transmission of electrical signals or hydraulic media, reducing system failures caused by connection failures at their source and guaranteeing the continuous operation capability of the equipment. In terms of connectivity, the 803165999 connector’s pins and sockets are precision-stamped and electroplated, resulting in extremely low contact resistance and excellent conductivity. In electrical signal transmission, it ensures accurate transmission of control commands and sensor data, preventing equipment malfunctions and monitoring failures caused by signal delays or loss. In hydraulic media transmission, its smooth internal flow channel design minimizes pressure loss, ensuring efficient flow of oil and other media, contributing to rapid response and sufficient power in hydraulic systems. The optimized mating structure provides uniform and moderate mating force, ensuring a secure connection while facilitating quick assembly and disassembly for maintenance.

Sealing protection is one of the connector’s core advantages. Employing a multi-seal design, the interface is equipped with a high-quality oil-resistant sealing ring and dust cap, achieving a protection rating of IP67 or higher. Effectively preventing dust, moisture, oil, and other impurities from entering the interior, it maintains internal cleanliness and dryness even in damp, muddy, and dusty mining or construction sites. This avoids short circuits, blockages, or component corrosion caused by contaminants, significantly extending the connector’s lifespan and reducing maintenance frequency.

In terms of structural design, the 803165999 connector features a precise and reliable positioning guide structure, enabling quick alignment during installation and avoiding the risk of incorrect insertion. The outer shell surface has clear markings and a foolproof design, facilitating quick identification and correct installation by operators, reducing assembly errors. Simultaneously, the connector’s fixing method is robust and reasonable, tightly connecting to the equipment body via bolts or clips, preventing displacement or loosening even in environments with severe vibration, ensuring long-term stability of the connection.

Regarding compatibility, the 803165999 connector is an original accessory for the XCMG XE2000 excavator, perfectly matching the interface specifications and installation dimensions of the corresponding system. Whether it’s connecting sensors and solenoid valves in the electrical control system or docking pipelines and valve groups in the hydraulic system, seamless adaptation is achieved. The installation process requires no modification to the original equipment structure; assembly can be completed quickly by following the original manufacturer’s specifications, ensuring that the connected system performance meets design standards and reducing commissioning time.

This connector excels in durability and environmental adaptability. Metal components undergo corrosion-resistant plating treatment, resisting the erosion of harsh environments such as acids, alkalis, and salt spray; plastic components use aging-resistant and high/low temperature resistant materials, maintaining stable performance within a temperature range of -40℃ to 125℃, and are not prone to cracking or deformation over long-term use. Rigorous vibration, impact, and life tests ensure reliable connection throughout the entire lifecycle of the XE2000 excavator.

When you need to replace the connector for your XCMG XE2000 excavator, choosing the original product with part number 803165999 means choosing the stable core of your system connection. With its precise connectivity, robust protective design, and original equipment manufacturer (OEM) compatibility, it safeguards the efficient and coordinated operation of all excavator systems, reduces equipment downtime caused by connectivity issues, and allows you to work with peace of mind in various complex construction scenarios, fully promoting project progress.

Get a personalized quote now

*For other spare parts procurement needs, please contact us!

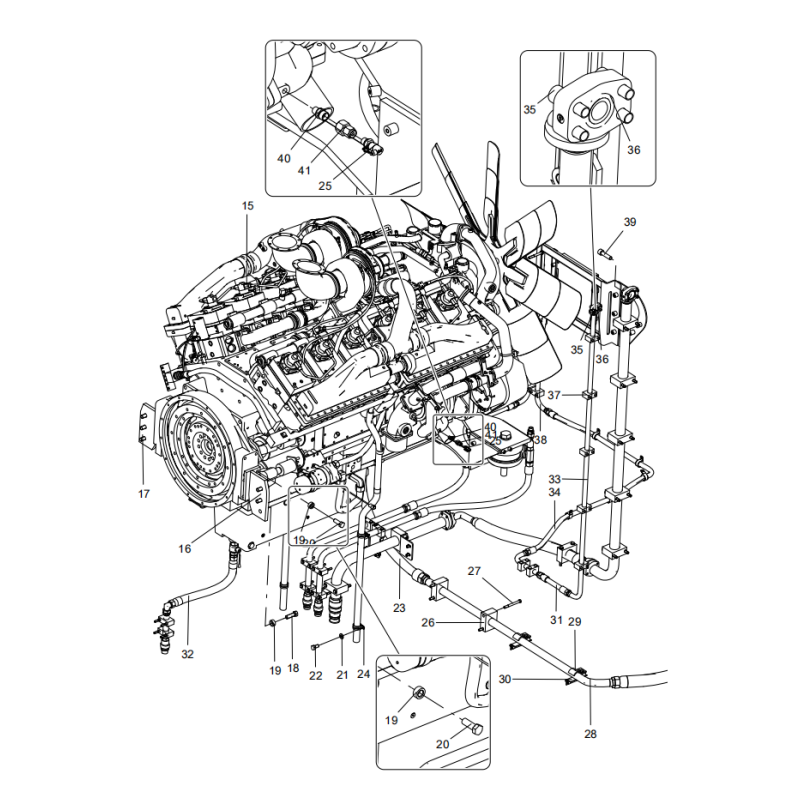

318306873 Engine mounting assembly XCMG XE2000 excavator spare parts

15 800157114 1 ENGINE ASSEMBLY

16 318306870 1 REAR OUTRIGGERS

17 318306863 1 REAR OUTRIGGERS

18 805006285 6 BOLT M20×65 GB/T5783-2000

19 318300798 12 WASHER

20 318300797 6 BOLT

21 805338277 5 WASHER 8 GB/T97.1-2002

22 805046503 5 BOLT M8×16 GB/T5783-2000

23 803419823 1 HOSE ASS’Y

24 801905468 4 RUBBER SLEEVE HOOP

25 803094858 2 SAMPLING VALVE

26 800166891 2 PIPE CLIP

27 805046433 4 BOLT M12×120 GB/T5782-2000

28 318300841 1 STEEL PIPE ASSEMBLY

29 329900502 2 PIPE CLIP

30 318800858 2 STEEL PIPE BRACKET B

31 803419818 1 HOSE ASS’Y

32 318300809 1 QUICK FILLING SYSTEM

33 318300811 1 STEEL PIPE ASSEMBLY

34 800166919 1 DIESEL PIPE

35 805139764 4 SCREW M10×30 GB/T70.1-2008

36 803192086 1 ORING 25.8×3.55 GB/T3452.1-2005

37 800153391 11 PIPE CLAMP ASSEMBLY

38 318300813 3 STEEL PIPE ASSEMBLY

39 805139929 4 SCREW M10×40 GB/T70.1-2008

40 803165999 1 CONNECTOR

41 803426651 2 CONNECTOR